PCBA solder joint inspection method based on machine vision

A technology of solder joint detection and machine vision, which is applied in the field of PCBA solder joint detection based on machine vision, can solve problems such as thinning tin, insufficient smoothness, and high labor costs, and achieve the goals of overcoming difficult resolution, improving detection efficiency, and reducing labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

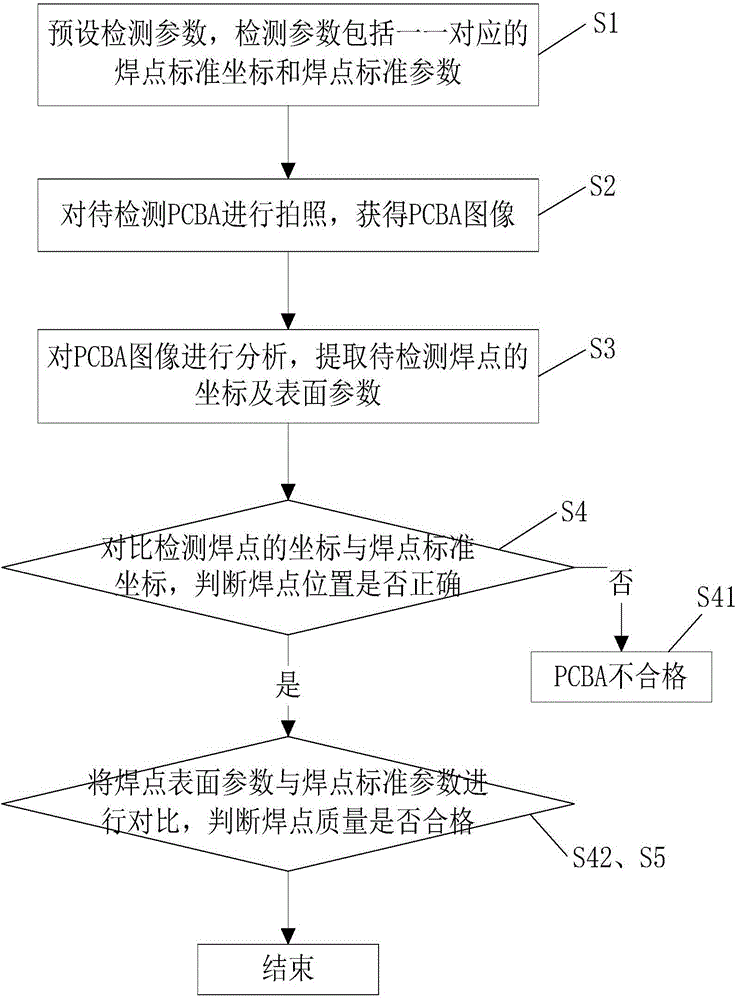

[0022] refer to figure 1 , a PCBA solder joint detection method based on machine vision proposed by the present invention, judges the position and quality of solder joints through image acquisition and analysis, with high accuracy and low labor cost.

[0023] A kind of PCBA solder spot detection method based on machine vision that the present invention proposes specifically comprises the following steps:

[0024] S1. Preset detection parameters. The detection parameters include one-to-one corresponding solder joint standard coordinates and solder joint standard parameters.

[0025] The solder joints are used to fix the components on the circuit board, so the positions of the solder joints on the same PCBA should be the same. Therefore, after selecting a fixed origin on the circuit board, the coordinates of the solder joints relative to the origin should be is consistent.

[0026] In this embodiment, the standard coordinates of the solder joints are the coordinates of the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com