Automatic test system and method for industrial production process control logic

An automatic test system and industrial production technology, applied in the direction of electrical testing/monitoring, etc., can solve problems such as endangering the environment and life safety, wrong detection and missed detection, time-consuming, etc., to achieve high efficiency and cost, verification reliability, and convenience Corrected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

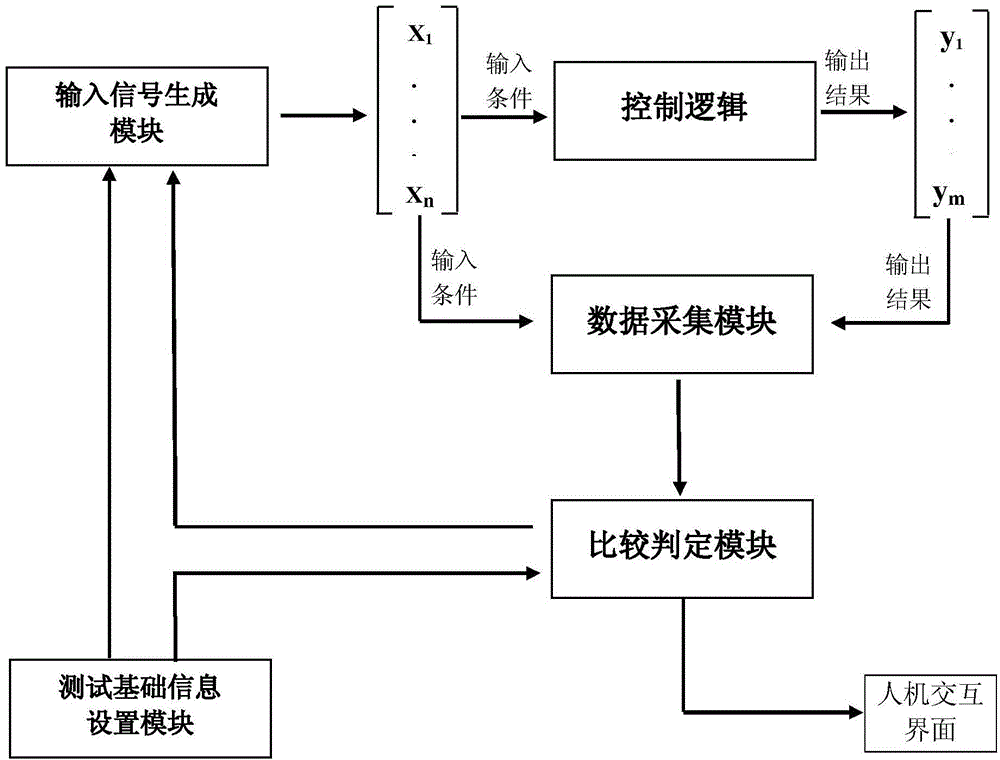

[0040] In order to describe the technical content, purpose and effect of the present invention in detail, the following will be further described in detail in conjunction with the accompanying drawings and specific implementation methods.

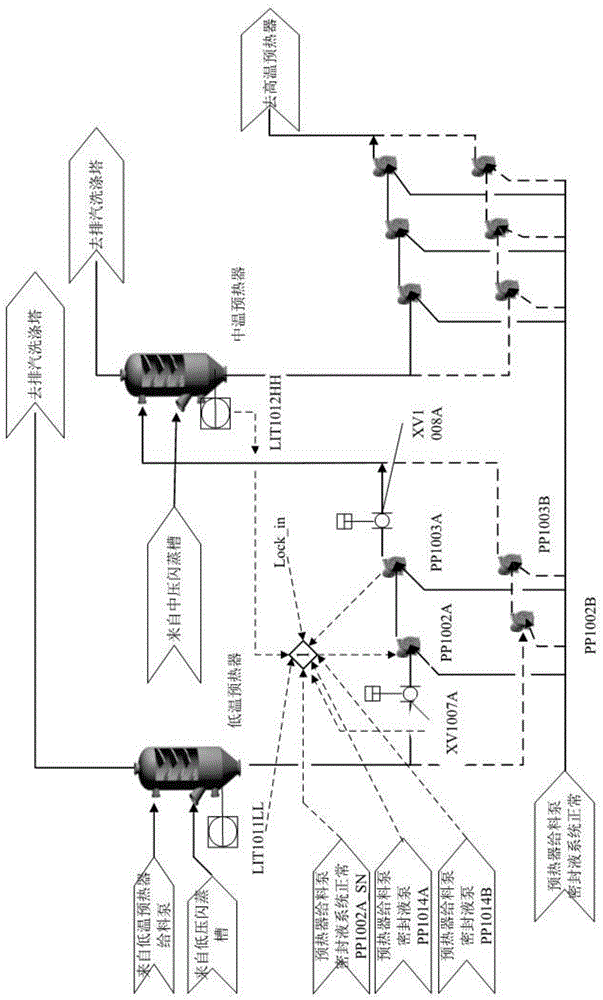

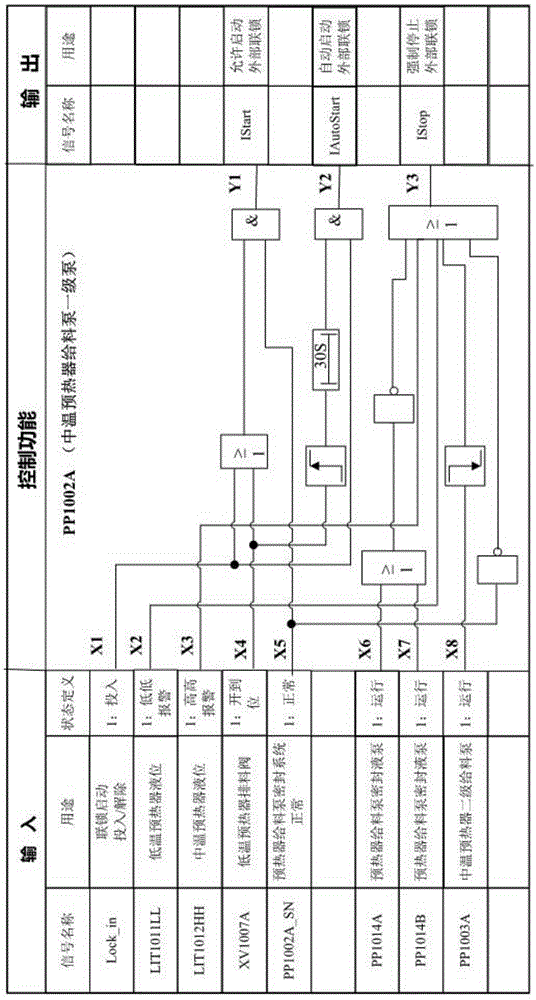

[0041] In this embodiment, if figure 1 As shown, it is the first two stages in the three-stage heating process of a certain production site, that is, the low-temperature preheater and the medium-temperature preheater. There are 2 feed pumps connected in parallel between each two-stage preheater, and each feed pump It is also connected in series. The control logic of the test in this embodiment is aimed at the first-stage pump of a certain road, that is, the previous pump of the two-stage series pump (the logic of the other pump is the same as this pump), for example, PP1002A is a stage pump. figure 1 The secondary pump of a certain road is the last pump of the two-stage series pump on the road, such as PP1003A.

[0042] This example is ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com