Multi-phase permanent magnet direct current motor

A permanent magnet DC, multi-phase technology, applied in motors, synchronous motors with stationary armatures and rotating magnets, electric vehicles, etc., can solve problems such as harmonic heating, output torque imbalance of permanent magnet DC motors, etc. Achieve the effect of small starting current, low modification cost and simple control equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

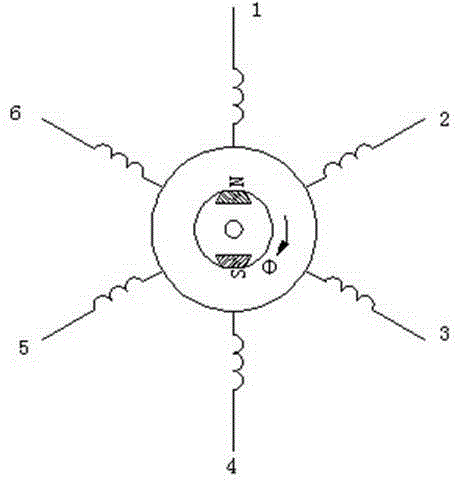

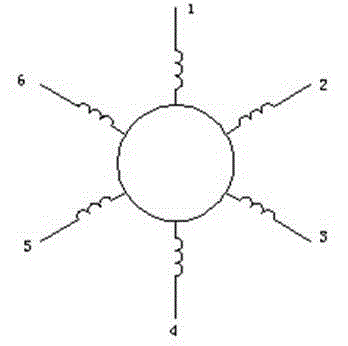

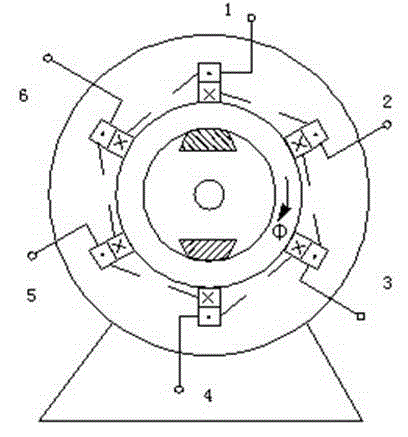

[0010] The multi-phase permanent magnet DC motor is composed of a stator, a rotor and a power supply device; the magnetic poles of the rotor are permanent magnet poles made of ferrite or rare earth permanent magnet materials; the stator has 12 np slots, n=1 / 2, 1 , 2, 3..., p is the number of pole pairs (that is, there are 12n slots under each pole pair of the stator), and each pole pair of the stator is provided with six-phase windings with symmetrical distribution and equal turns, with different pole pairs The lower in-phase windings are connected in series or in parallel, and the outlet ends of the phase windings are connected to each other; the power supply device continuously supplies power to the stator windings according to the position and speed of the rotor in the following order: the inlet ends of the first phase winding are positive and the fourth The incoming end of the phase winding is negative, the incoming end of the second phase winding is positive, the incoming e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com