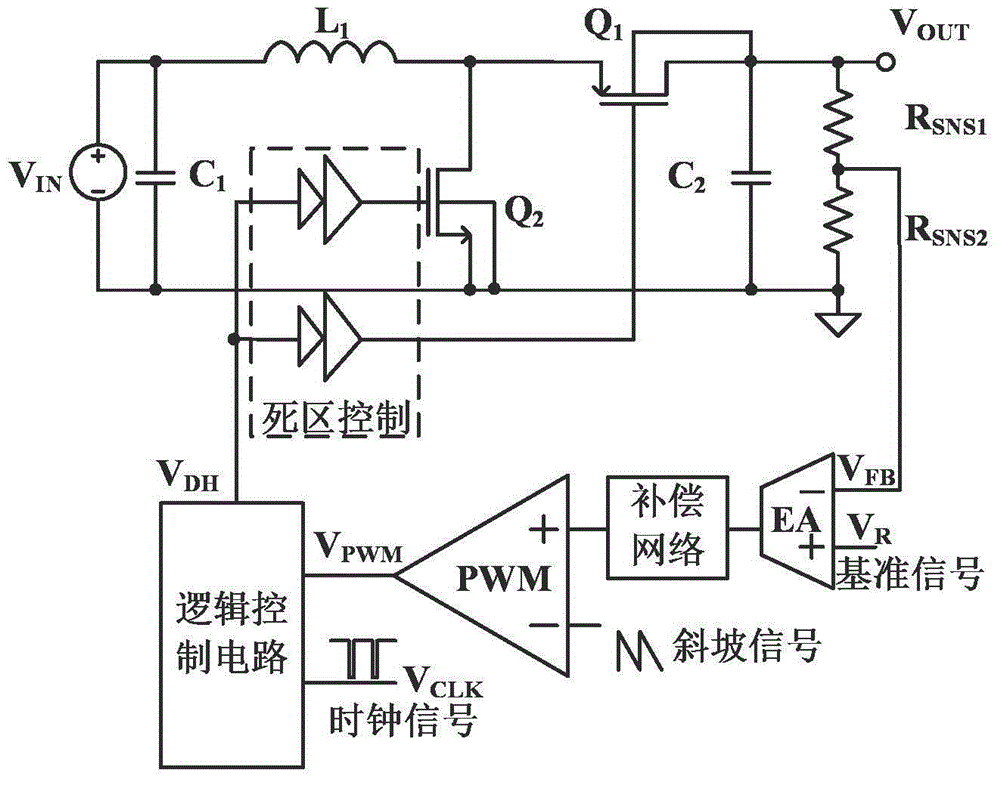

Boost type DC-DC converter synchronous power tube current limiting circuit

A DC-DC, synchronous power technology, applied in the direction of output power conversion devices, electrical components, etc., can solve problems such as damage to power tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

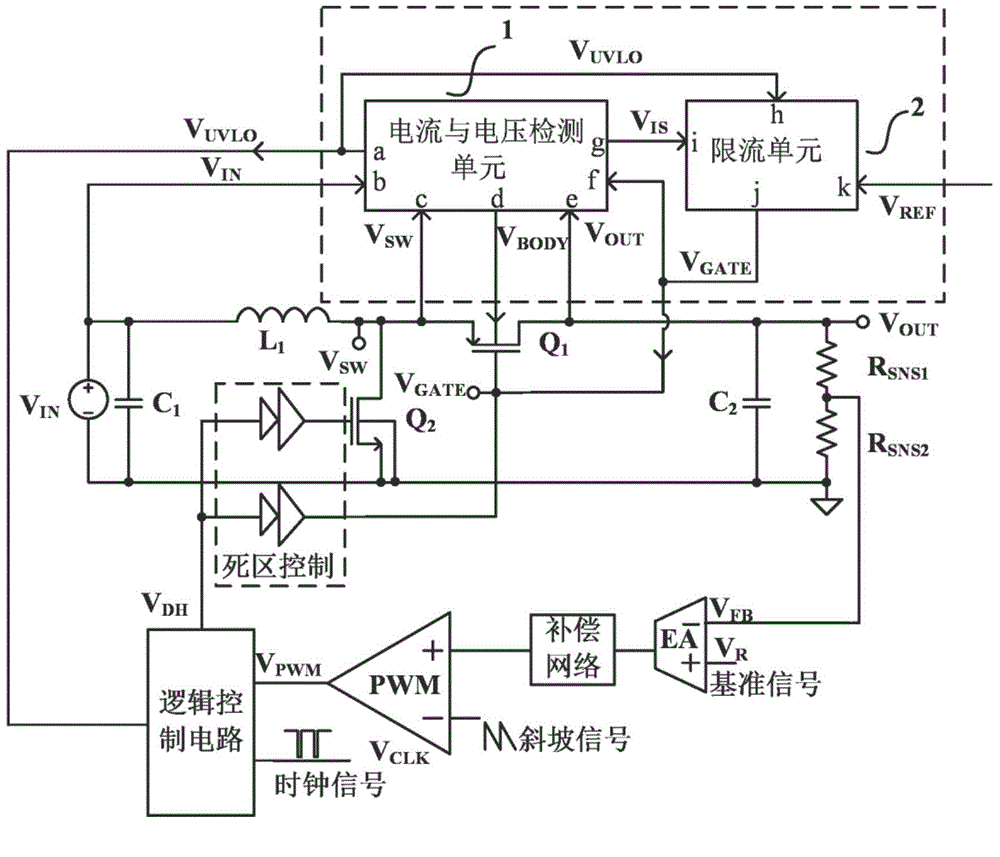

[0056] refer to figure 2 , the Boost type DC-DC converter synchronous power tube current limiting circuit of the present invention includes a current and voltage detection unit 1 and a current limiting unit 1 .

[0057] The voltage and current detection unit 1 is provided with four input terminals b, c, e, f and three output terminals a, d, g; the current limiting unit 2 is provided with three input terminals h, i, k and a Output terminal j; where the first input terminal b of the voltage and current detection unit 1 is connected to the input voltage V IN ; The second input terminal c, the third input terminal f and the fourth input terminal e are respectively connected to the synchronous power transistor Q 1 The source, gate and drain of the switch node voltage V SW , gate control signal V GATE and the output voltage V OUT ; Wherein the first output terminal a outputs the undervoltage control signal V UVLO To the undervoltage control terminal of the logic control circui...

Embodiment 2

[0079] The current and voltage detection unit 1 of this embodiment is the same as that of the first embodiment.

[0080] refer to Figure 5 , the current limiting unit 2 of the present embodiment includes an inverter 201, a current source I S1 , PMOS tube M 201 , PMOS tube M 202 , PMOS tube M 203 , PMOS tube M 204 , PMOS tube M 207 , PMOS tube M 208 , PMOS tube M 211 , NMOS tube M 205 , NMOS tube M 206 , NMOS tube M 209 , NMOS tube M 210 and NMOS tube M 212 ;in:

[0081] The current source I S1 , whose input terminal is connected to the internal power supply V DD , whose output terminal is connected to the PMOS tube M 201 and M 202 on the source;

[0082] The PMOS tube M 201 The gate and current sampling signal V IS Connected, and its drains are respectively connected to the NMOS transistor M 206 The drain and NMOS transistor M 205 The source is connected; PMOS tube M 202 gate with an external reference voltage V REF Connected, and its drains are respect...

Embodiment 3

[0090] The current limiting unit 2 in this embodiment is the same as that in Embodiment 1.

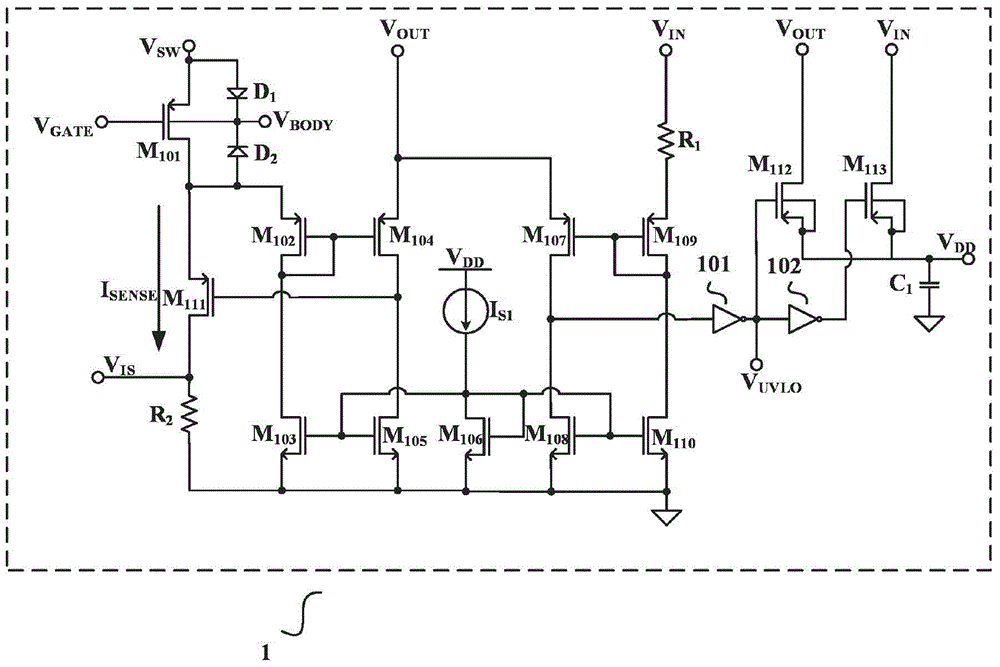

[0091] refer to Image 6 , the current and voltage detection unit 1 of the present embodiment includes an inverter 101, an inverter 102, a current source 1 S1 , the first resistor R 1 , the second resistance R 2 , the third resistor R 3 , the fourth resistor R 4 , the fifth resistor R 5 , the first diode D 1 , the second diode D 2 , the first capacitance C 1 , Power mirror PMOS tube M 115 , PMOS tube M 101 , PMOS tube M 103 , PMOS tube M 105 , PMOS tube M 111 , PMOS tube M 113 , PMOS tube M 116 , PMOS tube M 117 , PMOS tube M 118 , NMOS tube M 102 , NMOS tube M 104 , NMOS tube M 106 , NMOS tube M 107 , NMOS tube M 108 , NMOS tube M 109 , NMOS tube M 110 , NMOS tube M 112 and NMOS tube M 114 . in:

[0092] The current source I S1 , whose input terminal is connected to the internal power supply V DD , whose output terminal is connected to the NMOS tube M 107...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com