Automatic weed removal method

An automatic cleaning and weeding technology, applied in the field of farmland management, can solve the problems of low weeding efficiency, manpower consumption, and weeding area restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

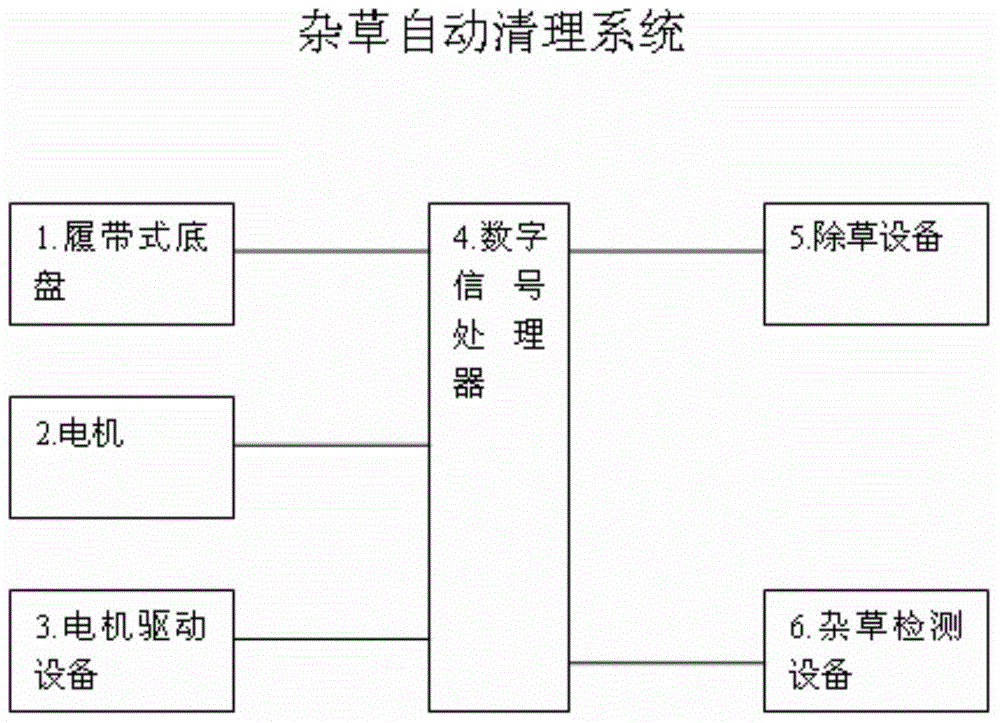

[0015] Embodiments of the automatic weed cleaning system of the present invention will be described in detail below with reference to the accompanying drawings.

[0016] In the past, the most commonly used method of weeding was to spray pesticides on the farmland to kill the target species of weeds in a targeted manner and maintain the healthy growth of normal crops. This method is widely used because of its convenience, and even some farmland management departments use mechanical methods to spray pesticides in large areas. Although pesticide weeding has the advantages of quick effect and high efficiency to a certain extent, on the one hand, the extensive use of pesticides brings chemical pollution to the natural environment, and the pollution will become more and more serious after long-term use. It will also have a certain impact on the growth of normal crops.

[0017] In order to avoid the harm of pesticides to the natural environment and crops, some countries and regions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com