Preparation method and application of hydrolyzed hydrogen cyanide catalyst

A catalyst and hydrogen cyanide technology, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., to achieve high selectivity and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

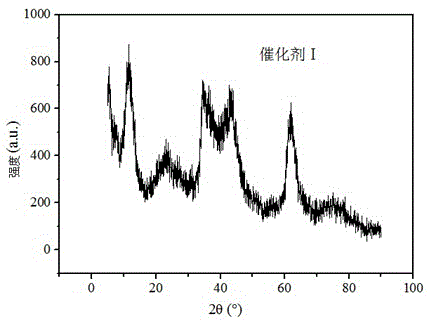

Embodiment 1

[0022] In this embodiment, the method for preparing a hydrogen cyanide hydrolysis catalyst using Cu-Zn-Al hydrotalcite as a precursor is as follows:

[0023] (1) Take 0.02mol Cu(NO 3 ) 2 ·6H 2 O, 0.1mol Zn(NO 3 ) 2 ·6H 2 O and 0.12mol Al(NO 3 ) 3 9H 2 O was dissolved in distilled water and configured as solution A, in which Cu 2+ and Zn 2+ The molar ratio of Cu, Zn and A is 0.2:1, and the molar ratio of Cu, Zn and A is 1:1; take 0.144mol NaOH and 0.06mol NaOH 2 CO 3 Dissolve in distilled water to make solution B 1 , so that where OH - with Cu 2+ , Zn 2+ and Al 3+ The molar ratio of the sum is 0.6:1, CO 3 2- with Al 3+ The molar ratio is 0.5:1.

[0024] (2) Drop the prepared solution A and solution B into a three-necked flask filled with an appropriate amount of water at the same time at a rate of 1 drop / second, so that the volume ratio of the sum of solutions A and B to the water in the three-necked flask is 0.5:1, while maintaining vigorous stirring, contr...

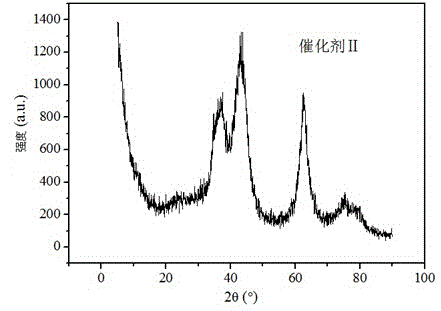

Embodiment 2

[0029] In this embodiment, the method for preparing a hydrogen cyanide hydrolysis catalyst using Cu-Zn-Al hydrotalcite as a precursor is as follows:

[0030] (1) Weigh 0.02mol Cu(NO 3 ) 2 ·6H 2 O, 0.01mol Zn(NO 3 ) 2 ·6H 2 O and 0.01mol Al(NO 3 ) 3 9H 2 O was dissolved in distilled water to prepare solution A, so that the molar ratio of Cu and Zn was 2:1, and the molar ratio of the sum of Cu, Zn and Al was 3:1; 0.08mol NaOH and 0.03mol NaOH were used 2 CO 3 Dissolve in distilled water to make solution B, where OH - with Cu 2+ , Zn 2+ and Al 3+ The molar ratio of the sum is 2:1, CO 3 2- with Al 3+ The molar ratio is 3:1.

[0031] (2) Drop the prepared solution A and solution B into a three-necked flask filled with an appropriate amount of water at the same time at a rate of 1 drop / second, so that the volume ratio of the sum of solutions A and B to the water in the three-necked flask is 2:1, while stirring vigorously, control the pH of the system to 11, and then...

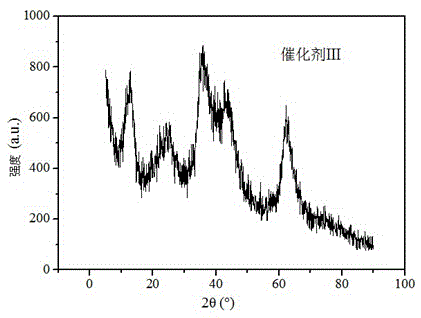

Embodiment 3

[0036] In this embodiment, the method for preparing a hydrogen cyanide hydrolysis catalyst using Cu-Zn-Al hydrotalcite as a precursor is as follows:

[0037] (1) Weigh 0.02mol Cu(NO 3 ) 2 ·6H 2 O, 0.02mol Zn(NO 3 ) 2 ·6H 2 O and 0.02mol Al(NO 3 ) 3 9H 2 Dissolve O in distilled water and prepare solution A, so that the molar ratio of Cu and Zn is 1:1, and the molar ratio of the sum of Cu, Zn and Al is 2:1; take 0.078mol NaOH and 0.04mol NaOH 2 CO 3 Dissolve in distilled water to make solution B, where OH - with Cu 2+ , Zn 2+ and Al 3+ The molar ratio of the sum is 1.3:1, CO 3 2- with Al 3+ The molar ratio is 2:1.

[0038] (2) Drop the prepared solution A and solution B into a three-necked flask filled with an appropriate amount of water at the same time at a rate of 1 drop / second, so that the volume ratio of the sum of solutions A and B to the water in the three-necked flask is 1:1, while stirring vigorously, control the pH of the system to 9, and then crystall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap