Boron modified Y-type molecular sieve and preparation method thereof

A molecular sieve and modification technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Unsatisfactory effect and other problems, to achieve the effect of improving acidity and pore structure performance, increasing proportion, and strengthening acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

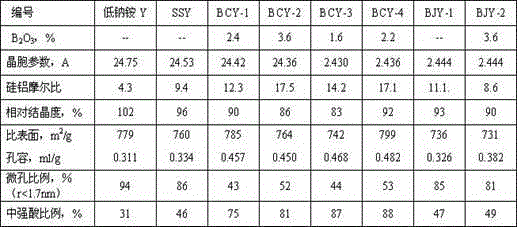

Examples

preparation example Construction

[0026] The preparation method of modified Y molecular sieve of the present invention specifically comprises the following steps:

[0027] (1) Take an appropriate amount of ammonium fluoroborate crystals, gradually add them into distilled water stirred at a temperature of 30-60°C, filter out impurities in the solution, and prepare a clear, transparent and stable ammonium fluoroborate solution.

[0028] (2) Take an industrially produced low-sodium Y molecular sieve with a sodium oxide content of 0.5~2.0wt%, put it into the ammonium fluoroborate solution under stirring, the solid-liquid ratio is 3:1~10:1, and the temperature of the solution rises to 80~100°C , you can turn on the ultrasonic instrument, place the mixed slurry under ultrasonic irradiation, the ultrasonic frequency is 40-100kHz, and the power is 2-40W / m according to the volume of the solution. The following dealumination and boron supplementation reactions occur in the slurry system:

[0029] NH 4 BF 4 +Al 3+ +N...

Embodiment 1

[0035] Measure 219.0 g of ammonium fluoroborate and gradually add it into 2000 mL of distilled water under stirring at 50°C to prepare an aqueous solution of ammonium fluoroborate. Get 500g industrial production low-sodium ammonium Y molecular sieve (Na 2 The O content is 1.1%, the crystallinity is 102%, and the unit cell constant is 2.475nm), molecular sieves are gradually added to the stirred ammonium fluoroborate aqueous solution, the temperature of the slurry is increased to 95°C, and the treatment is 60 minutes; first, the slurry is mixed with solid particles (fluoroaluminum Sodium acid) separation, and then solid-liquid separation, the filter cake was dried at 120 ° C for 6 hours; take the above 500g molecular sieve, and 200mL organic silicone oil ethanol solution (concentration 18.4gSiO 2 / 100mL) evenly sprayed onto the molecular sieve. Dry the impregnated molecular sieve at a temperature of 80°C for 3 hours; carry out a hydrothermal treatment of the molecular sieve co...

Embodiment 2

[0037] Change the low-sodium ammonium Y in Example 1 to SSY molecular sieve, adjust the concentration of ammonium fluoroborate solution to 15.2g / 100mL, make the beating solid-liquid ratio 1:5, beating temperature 70°C, beating time 2h, organic silicon into silicon oxide Alkane, other with example 1, numbering is BCY-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com