A method of using a hydraulic multi-axis flange bolt tightening device

A technology of elastic device and shaft flange, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of limited application range, high production cost, complicated production, etc., so as to avoid bolt loosening, low production cost and high torque uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

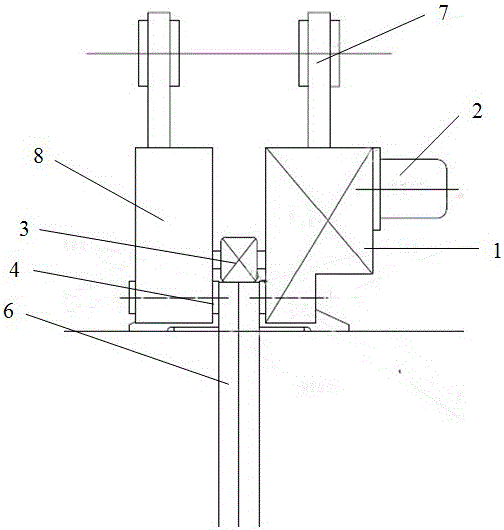

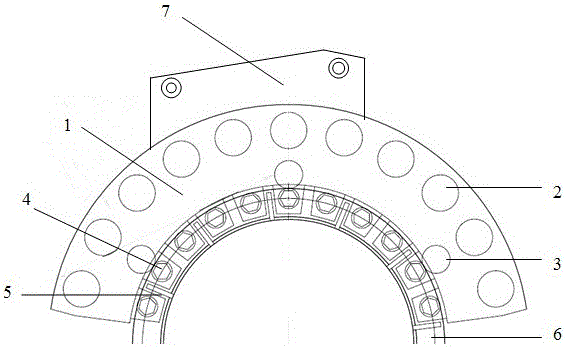

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0028] Such as figure 1 and figure 2 As shown, a hydraulic multi-axis flange bolt tightening device includes a main frame body 1 and a sub frame body 8, the main frame body 1 and the sub frame body 8 are semicircular, and the main frame body 1 and the sub frame body 8 are Both are equipped with a connecting seat 7, which can be directly connected with the mechanical arm of the backhoe excavator, such as being installed on the mechanical arm of the backhoe excavator, and the main frame body 1 and the auxiliary frame body 8 pass through three The connecting oil cylinder that controls the opening and closing of the frame and the 3 detachable positioning wheels 3 are connected. The main frame 1 is evenly equipped with 12 sets of reduction gears (not shown) and 12 hexagonal sleeves 4, corresponding to the outside of the main frame 1. There are 12 hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com