Numerical-control lathe tool table with convenience in assembling and disassembling tools

A technology of CNC lathe and tool table, which is applied in the direction of manufacturing tools, positioning devices, metal processing machinery parts, etc., and can solve the problem of single structure of CNC lathe tool table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

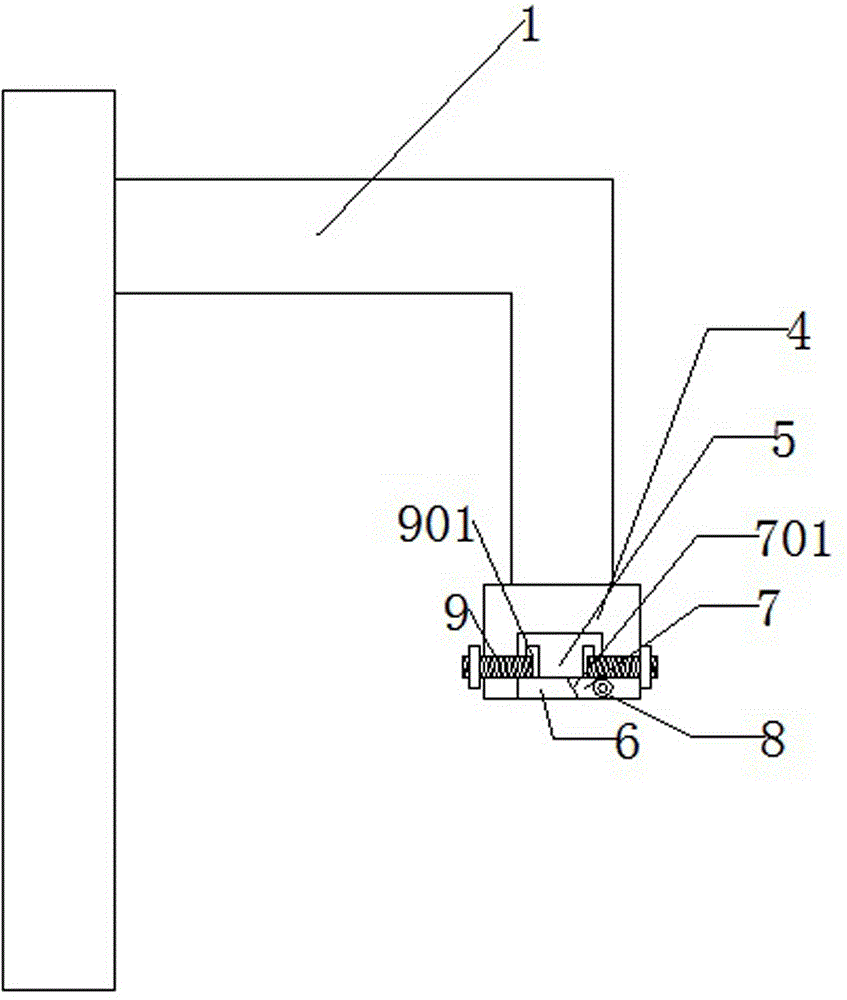

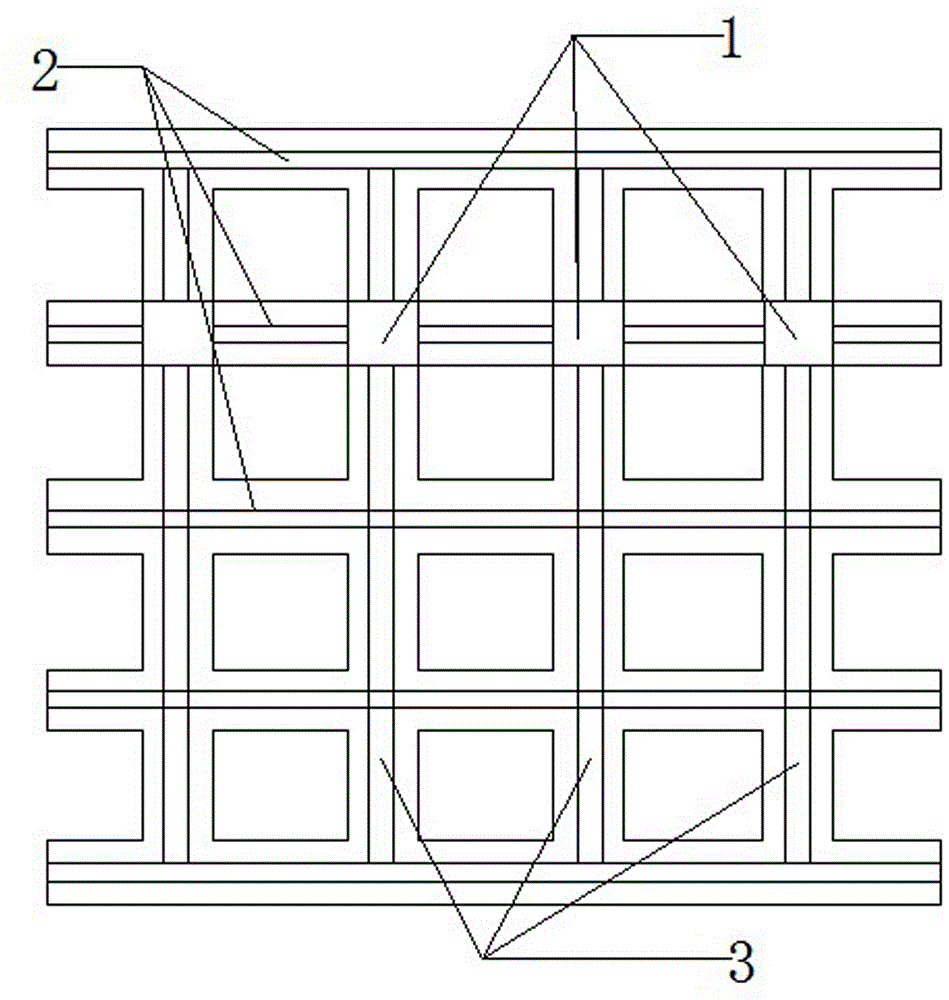

[0021] The CNC lathe tool table for convenient loading and unloading of tools includes: a moving component wall, a tool rack 1 that is movable at one end of the moving component wall, and an installation component fixed at the other end of the tool rack 1 and used for installing tools; the moving component wall includes: lateral moving parts, The vertical moving part intersecting with the lateral moving part, the mounting assembly includes: the mounting block 4 connected to the tool holder 1, the receiving groove 5 arranged on the mounting block 4 and used to accommodate the tool hook, the limit plate 6 of the limit hook, The movable plate 7 is clamped on the limiting plate 6 and closes the above-mentioned receiving groove 5, and stabilizes the position of the tool hook and runs through the limiting screw 9 of the mounting block 4; a hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com