Picking and conveying manipulator for heat transfer printing

A technology of manipulators and thermal transfer printing, applied in the direction of manipulators, rotary printing machines, printing machines, etc., can solve the problems that are not conducive to the control of enterprise costs, cannot meet the requirements of large-scale production, and cannot guarantee safety, so as to improve the appearance High quality, reduced mechanical damage, compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

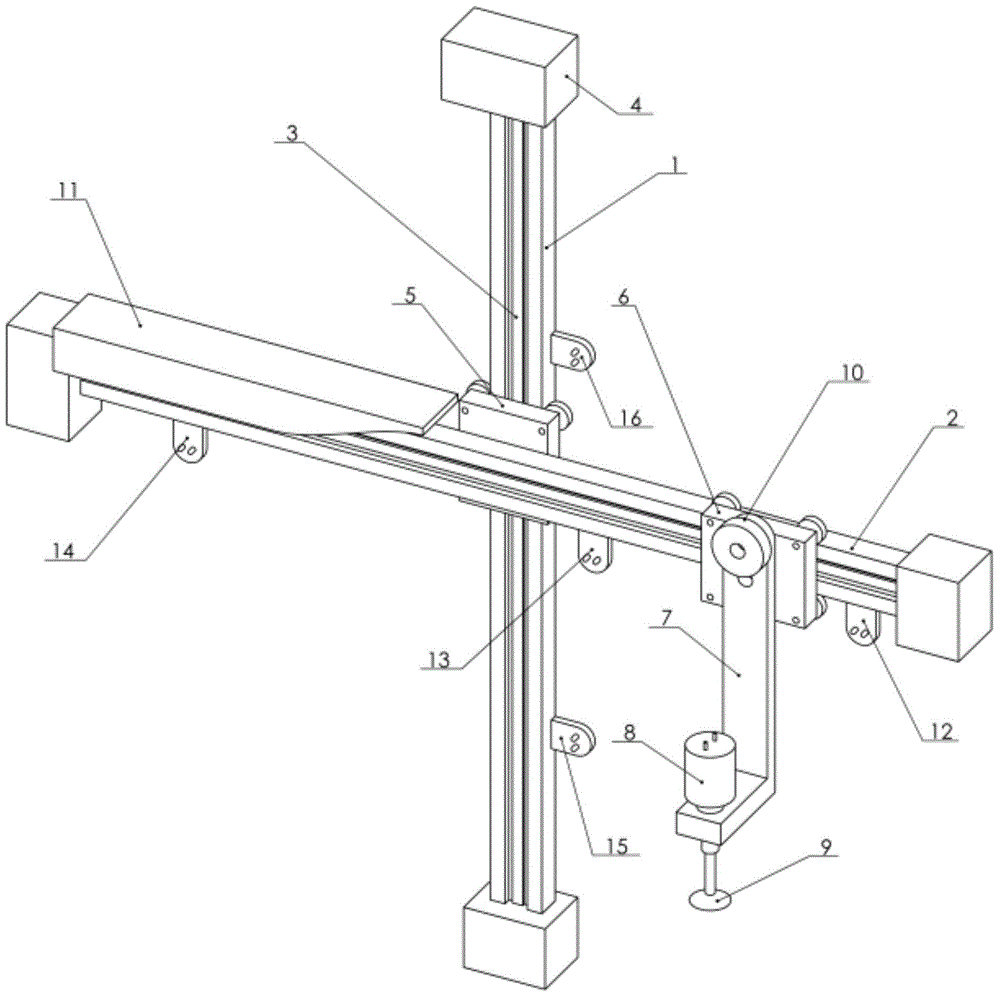

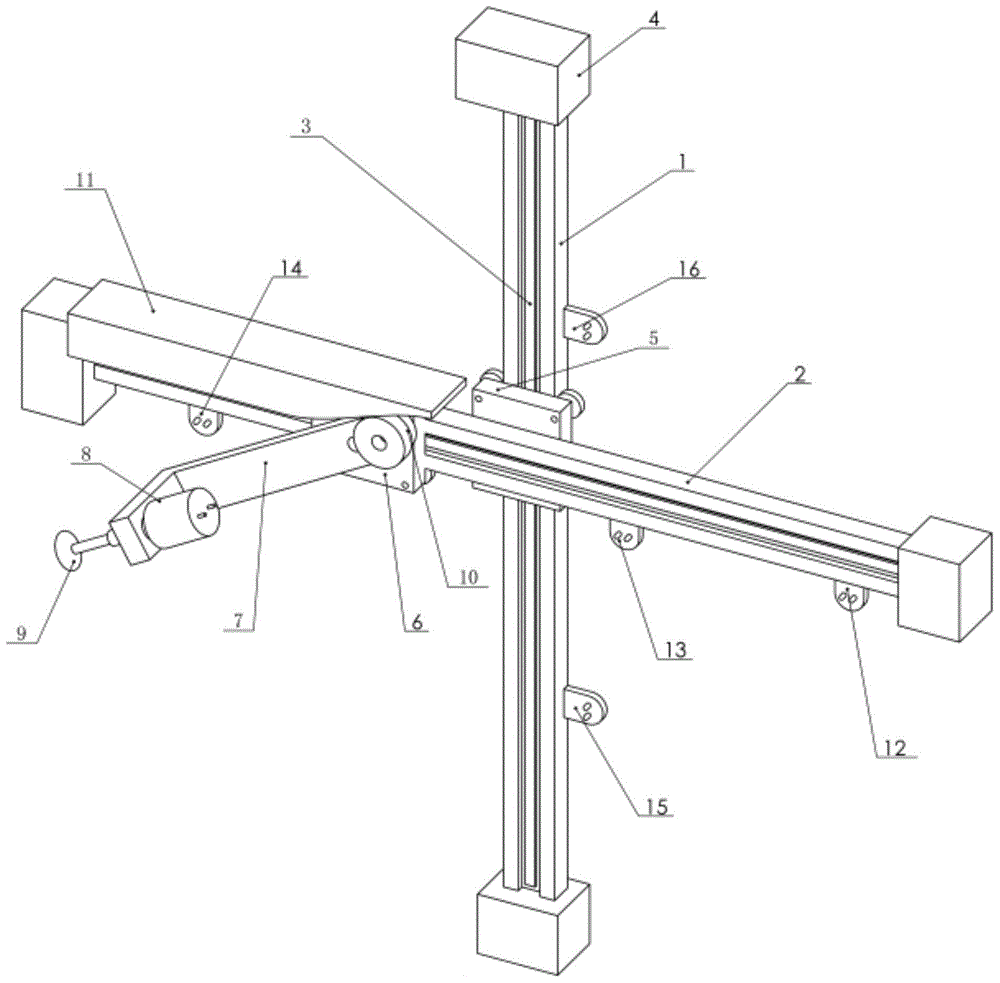

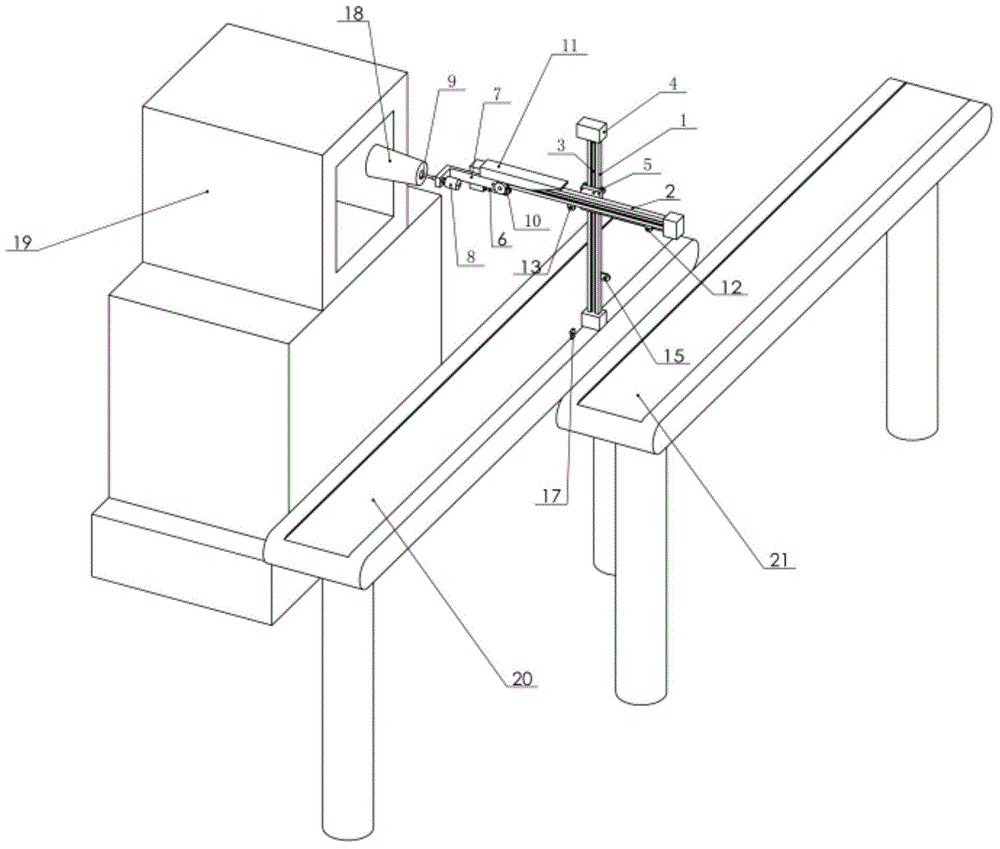

[0014] Such as Figure 1-Figure 3 As shown, the present invention is a thermal transfer material fetching and feeding manipulator, including a Z-axis linear guide rail 1, an X-axis linear guide rail 2, a belt 3, a stepping motor 4, a Z-axis slider 5, an X-axis slider 6, and a suction cup arm 7 , air pump motor 8, sucker 9, cam 10, cam rail 11, first infrared sensor 12, second infrared sensor 13, third infrared sensor 14, fourth infrared sensor 15 and fifth infrared sensor 16; wherein, the Z The axis linear guide 1 and the X axis linear guide 2 are installed in a cross shape; the Z axis linear guide 1 and the X axis linear guide 2 are equipped with a belt 3, and one end of the Z axis linear guide 1 and the X axis linear guide 2 are installed There is a stepping motor 4, the output shaft of the stepping motor 4 is mechanically connected to the belt 3 through g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com