A kind of production process of lightweight composite floor

A composite flooring and production process technology, applied in the field of flooring, can solve the problems of not being able to achieve good wear resistance, adhesion, polyurethane surface density should not be too large, and high probability of problems, so as to achieve good appearance and overall Good structural stability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

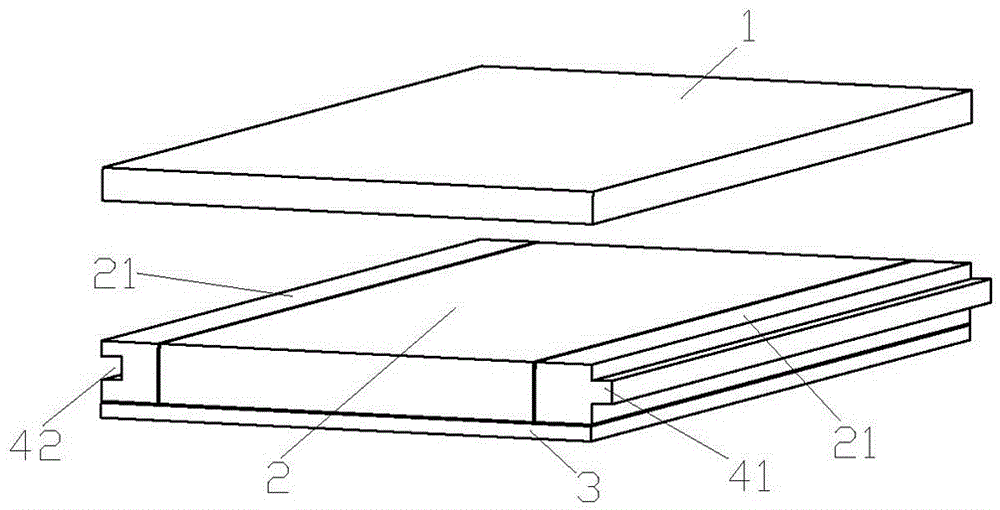

[0021] Example 1, such as figure 1 As shown, a production process of lightweight composite flooring includes steps in turn:

[0022] (1) Spare materials: use thin wood or thin bamboo or soft wood or EVA cushion or non-woven fabric as the bottom floor layer 3, cut into rectangular sheets of specified size and put them into the first automatic feeder, select Bamboo strips or wood strips or high-density glulam strips are used as rectangular strips 21 in the middle and put into the second automatic feeder. Bamboo boards or wood boards or high-density glulam boards are selected as the panel layer 1 and cut into specified sizes. rectangular sheet and put it into the third automatic feeder;

[0023] (2) One-time bonding: There is a guide roller conveying path, the bottom layer is continuously input from the entrance of the guide roller conveying path through the first automatic feeder, the bottom layer 3 is conveyed along the length direction, and the bottom layer 3 is convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com