Material melting device of color 3D printer

A 3D printer and melting device technology, applied in the field of 3D printer material melting device, can solve problems such as complex equipment structure, inability to provide pressure power, uniformity of molten products, poor stability, etc., and achieve good extrusion uniformity, suitable for popularization and application , the effect of heating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

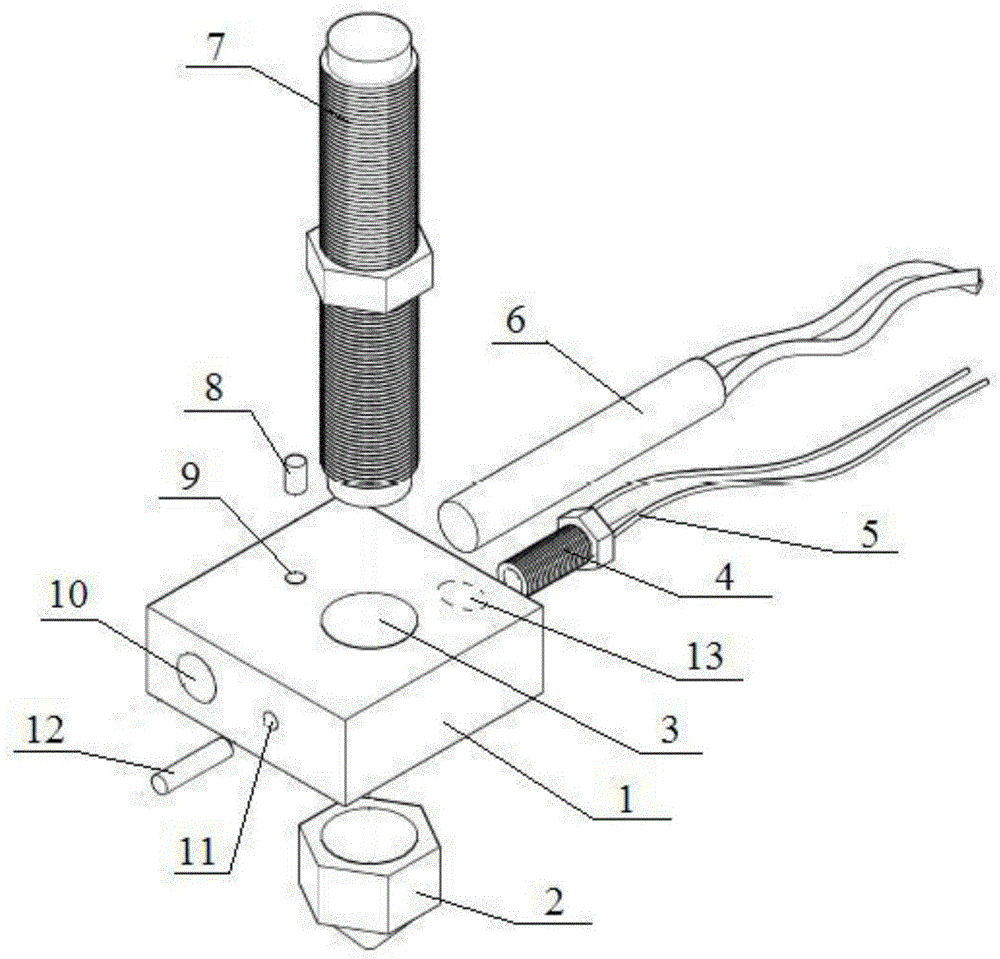

[0020] Such as figure 1 A material melting device for a color 3D printer is shown, comprising a support 1, a thermistor 5 installed on the support 1, a thermocouple 6, a heating tube 7, and a tapered nozzle 2 installed at the lower end of the heating tube 7, the support The front of 1 is provided with a first fixing hole 9 and a first through hole 3 passing through up and down, and the side of the bracket 1 is provided with a mounting hole 13, a second fixing hole 11 and a second through hole 10 passing through front and rear. A fixing hole 9 intersects with the second through hole 10, the installation hole 13 and the second fixing hole 11 both intersect with the first through hole 3, and the heating tube 7 is installed in the first through hole 3 and passes through the first through hole The through hole 3 is threadedly connected to the conical nozzle 2, the mounting hole 13 is internally threaded with a conductive stud 4 connected to the heating tube 7, the thermistor 5 is c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap