Main drive structure for high-speed servo press

A technology of servo presses and presses, applied to presses, stamping machines, manufacturing tools, etc., can solve the problems that the stamping efficiency cannot be greatly improved, the main drive structure cannot realize variable stroke stamping, and the structural layout is difficult. , to achieve the effects of simple structure, good transmission rigidity, low difficulty in assembly and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

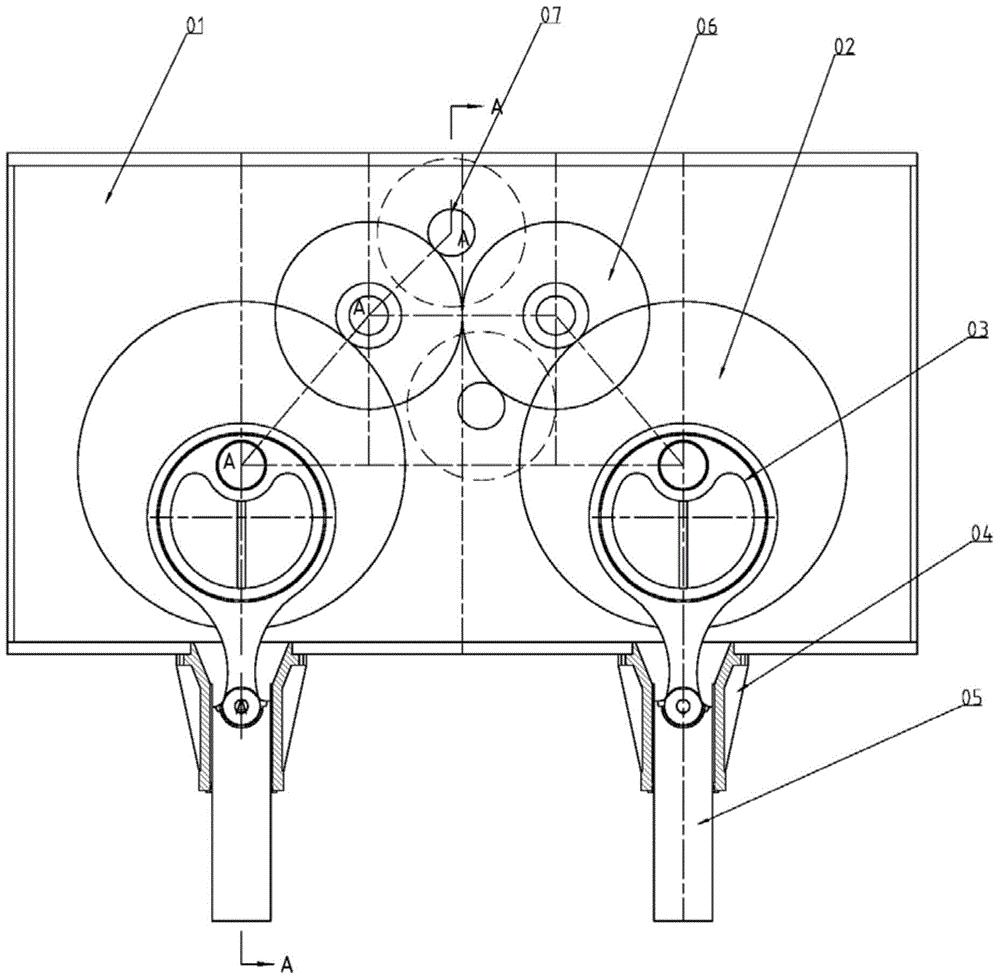

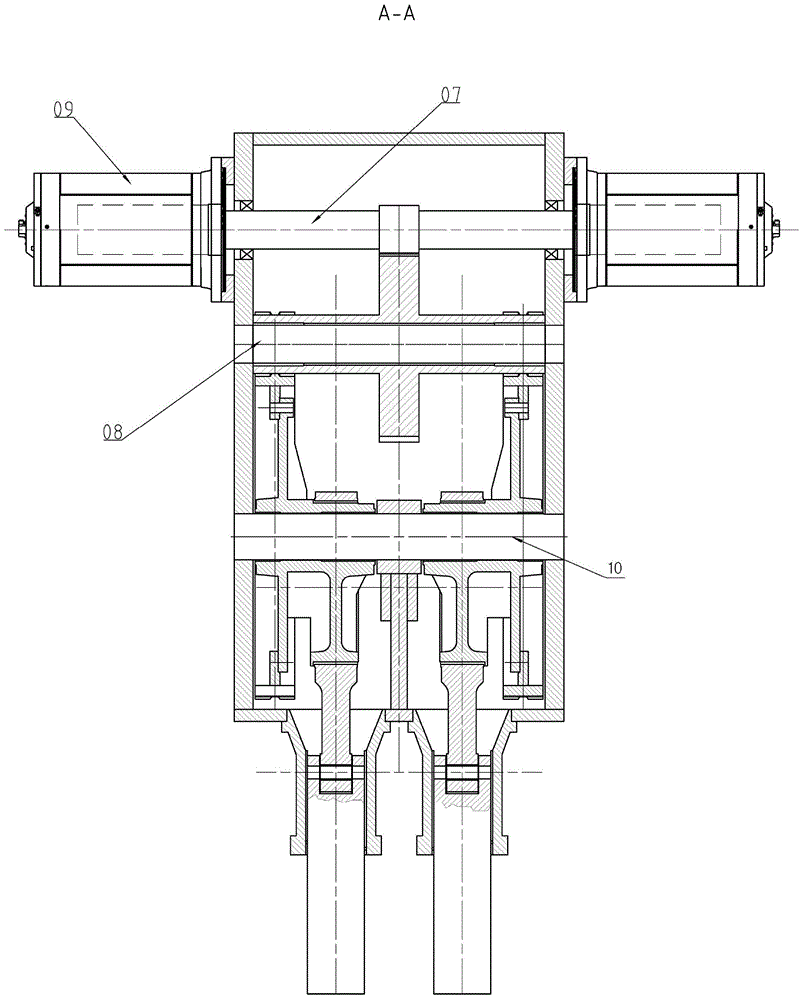

[0018] The present invention will be further described below in conjunction with drawings and embodiments. The embodiment is the main transmission structure of four servo motors.

[0019] Four servo motors 09 are installed on both sides of the upper beam 01 of the press, every two servo motors 09 are connected to both ends of a gear shaft 07 through splines, and four servo motors 09 are connected to both ends of two gear shafts 07 The gear shaft 07 is supported on the upper beam 01 of the press through bearings, and gear teeth are arranged in the middle of the gear shaft 07; the intermediate gear sleeve 06 is installed on the gear sleeve mandrel 08, and the two gear sleeve mandrels 08 are installed in parallel on the upper beam 09 of the press Below the gear shaft 07, the middle part of the intermediate gear sleeve 06 is provided with gear teeth that are larger than the outer diameter of the intermediate gear sleeve 06, and the two ends of the intermediate gear sleeve 06 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com