A printing machine variable tension control method

A tension control and printing machine technology, applied in printing machines, general parts of printing machinery, printing, etc., can solve the problems of constant tension adjustment and large waste products, and achieve the effects of reducing waste products, improving performance and reducing total cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

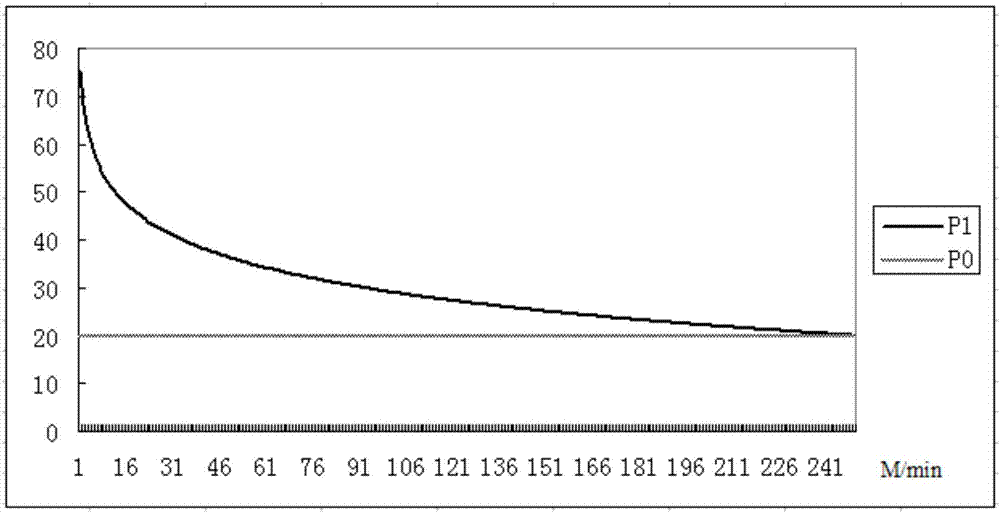

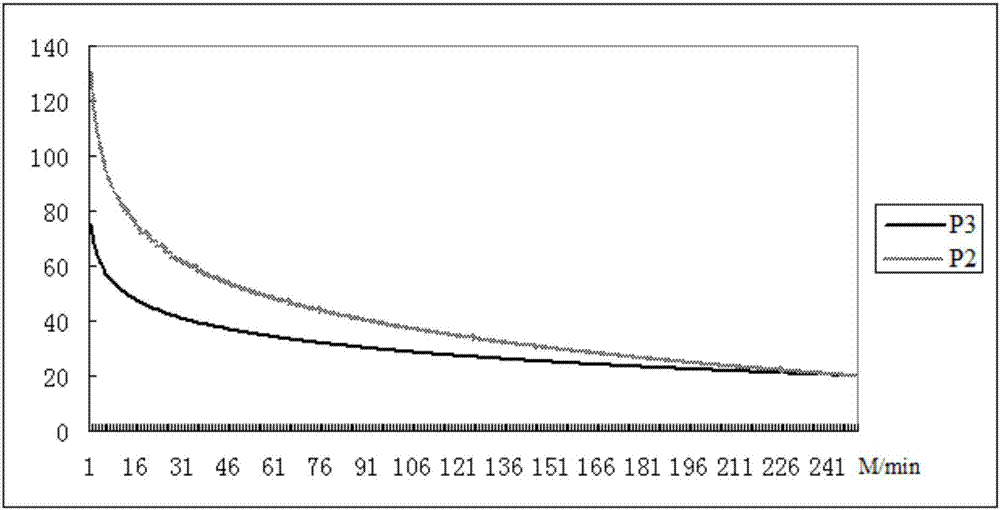

[0022] A method for controlling variable tension of a printing press satisfies the following functional relationship when controlling the speed of the printing press:

[0023] P=-Alnv+P 0 +B (1)

[0024] In the formula (1), P represents the tension adjustment amount,

[0025] v represents the speed of the machine,

[0026] P 0 Indicates the adjustment amount of the tension when the machine reaches a steady state;

[0027] A and B are adjustment parameters,

[0028] The relationship between A and B satisfies B=Aln(V max ) (2)

[0029] In formula (2), V max is the maximum speed of the machine;

[0030] Among them, A can change the decay speed and initial value of the tension adjustment amount, A=0.023mr 2 , where m is the mass of the roll and r is the radius of the roll. The value of A is related to the quality and radius of the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com