Self-adhesive quick-drying thermal sublimation transfer printing digital cloth

A self-adhesive, digital technology, applied in printing, copying/marking method, temperature recording method, etc., can solve the problems of low reuse rate, increase production cost, low yield, etc., to solve the problem of low recycling rate and save production. cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

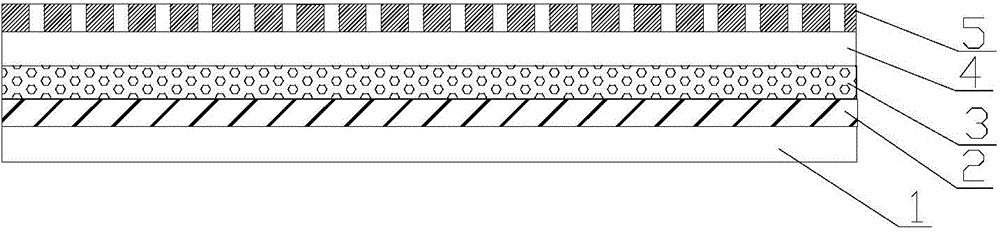

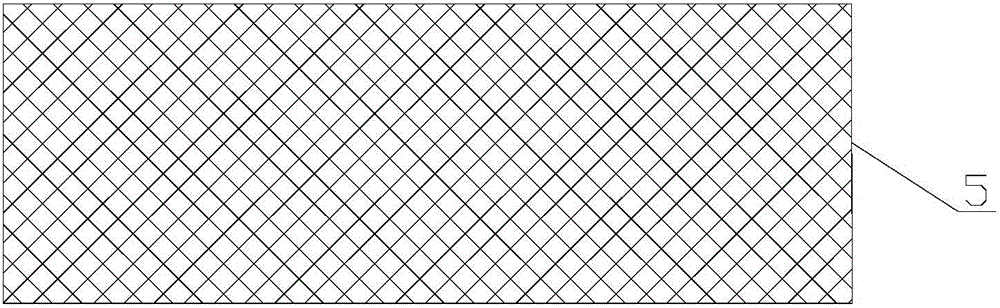

[0026] Self-adhesive fast-drying sublimation transfer printing digital cloth, such as Figure 1-2 As shown, it includes a digital substrate cloth 1 , a bonding water-permeable layer 2 , a water-absorbing layer 3 , an ink-absorbing layer 4 and a mesh surface layer 5 from bottom to top.

[0027] The bonding water-permeable layer 2 is water-based silicone modified acrylic resin. The water-based silicone-modified acrylic resin is a dimethyl silicone oil-modified acrylic resin or a methyl ethyl silicone oil-modified acrylic resin or a vinyl silicone oil-modified acrylic resin or a methylphenyl silicone oil-modified acrylic resin. The mass of the water-permeable layer 2 bonded on the digital substrate cloth 1 per square meter is 0.5 g.

[0028] The water-absorbing layer 3 includes void pores. The water-absorbing layer 3 is an acrylic acid-2-acrylamide-2-methacrylate sodium copolymer. The mass of the water-absorbing layer 3 on the digital substrate cloth 1 per square meter is 2 g....

Embodiment 2

[0032] Self-adhesive fast-drying sublimation transfer printing digital cloth, such as Figure 1-2 As shown, it includes a digital substrate cloth 1 , a bonding water-permeable layer 2 , a water-absorbing layer 3 , an ink-absorbing layer 4 and a mesh surface layer 5 from bottom to top.

[0033] The bonding water-permeable layer 2 is water-based silicone modified acrylic resin. The water-based silicone-modified acrylic resin is a dimethyl silicone oil-modified acrylic resin or a methyl ethyl silicone oil-modified acrylic resin or a vinyl silicone oil-modified acrylic resin or a methylphenyl silicone oil-modified acrylic resin. The mass of the water-permeable layer 2 bonded on the digital substrate cloth 1 per square meter is 2 g.

[0034]The water-absorbing layer 3 includes void pores. The water-absorbing layer 3 is acrylic acid-2-acrylamide-2-sodium methacrylate copolymer, and the mass of the water-absorbing layer 3 on the digital substrate cloth 1 per square meter is 3g.

...

Embodiment 3

[0038] Self-adhesive fast-drying sublimation transfer printing digital cloth, such as Figure 1-2 As shown, it includes a digital substrate cloth 1 , a bonding water-permeable layer 2 , a water-absorbing layer 3 , an ink-absorbing layer 4 and a mesh surface layer 5 from bottom to top.

[0039] The bonding water-permeable layer 2 is water-based silicone modified acrylic resin. The water-based silicone-modified acrylic resin is a dimethyl silicone oil-modified acrylic resin or a methyl ethyl silicone oil-modified acrylic resin or a vinyl silicone oil-modified acrylic resin or a methylphenyl silicone oil-modified acrylic resin. The mass of the water-permeable layer 2 bonded on the digital substrate cloth 1 per square meter is 0.6 g.

[0040] The water-absorbing layer 3 includes void pores. The water-absorbing layer 3 is acrylic acid-2-acrylamide-2-methacrylate sodium copolymer, and the mass of the water-absorbing layer 3 on the digital substrate cloth 1 per square meter is 2.5g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com