High-and-low pressure chamber closed-loop gas path electronic controlled air suspension system

An air suspension, high and low pressure technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the influence of height adjustment without specific design, no mention of control strategy, complex closed-loop air system structure, etc. problems, to achieve the effect of improving the body height adjustment performance, improving the body height adjustment performance, and increasing the electronic control strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

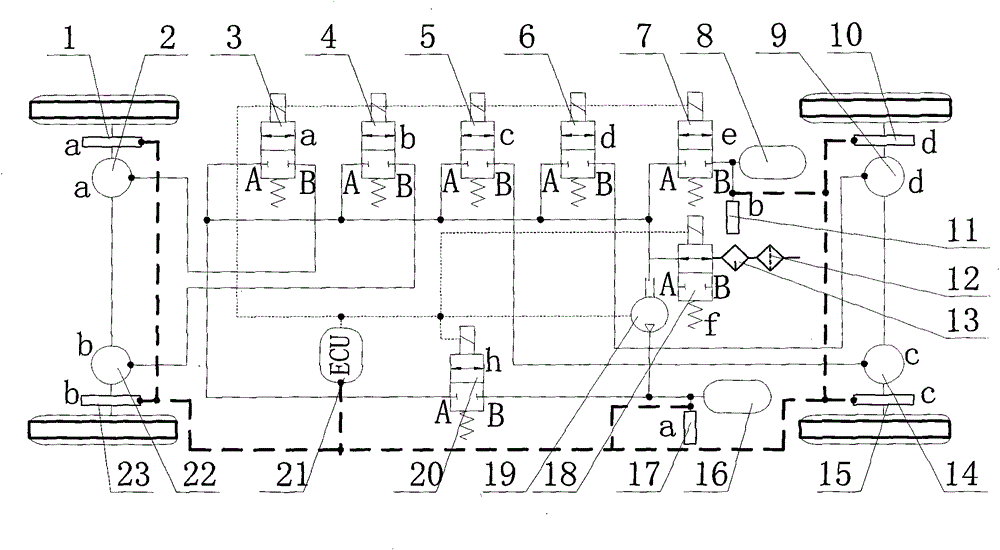

[0023] As shown in the figure, the high and low pressure cavity closed-loop air circuit electronically controlled air suspension system includes solenoid valve a3, solenoid valve b4, solenoid valve c5, solenoid valve d6, main deflation solenoid valve e7, solenoid valve f18, main inflation solenoid valve h20, Air spring a2, air spring b22, air spring c14, air spring d9, height sensor a1, height sensor b23, height sensor c15, height sensor d10, pressure sensor a17, pressure sensor b11, high pressure chamber 16, low pressure chamber 8, air pressure machine 19, electronic control unit ECU21, dryer 13, filter 12.

[0024] The high-pressure chamber 16 is connected in parallel to the hole B of the main charging solenoid valve h20 and the air outlet end of the air compressor 19, and the other end hole A of the main charging solenoid valve h20 is respectively connected in parallel to the hole A of the solenoid valve a3 and the hole A of the solenoid valve b4 , Hole A of solenoid valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com