Chain ring blowout preventer lifting and transferring device

A blowout preventer, chain-type technology, applied in the direction of hoisting device, transportation and packaging, load hanging components, etc., can solve the problems of poor pressure loss braking performance, poor running stability, poor corrosion resistance, etc., and achieve rapid start-up. , Reliable work, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

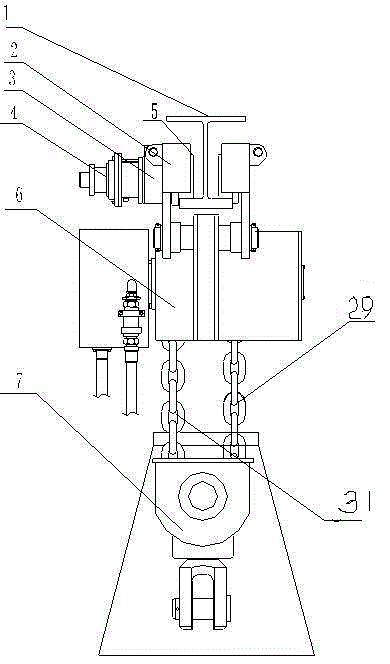

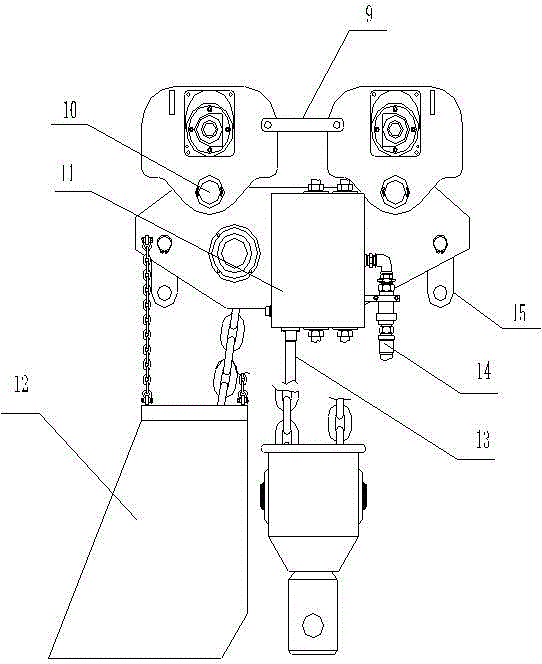

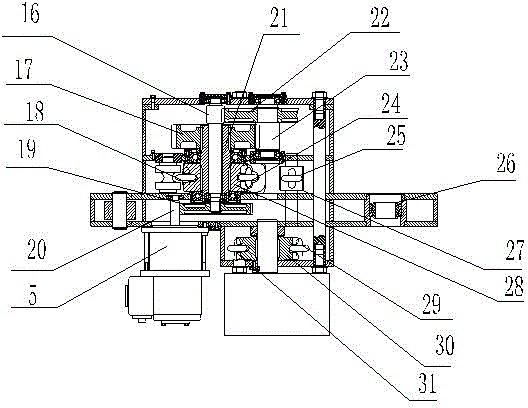

[0011] Such as figure 1 , figure 2 , image 3 As shown, a hoisting device for a ring-type BOP includes a guide rail 1, a trolley 2, a gearbox 3, a motor 4, wheels 5, a chain hoist 6, a hook frame 7, a connecting shaft 10, and a control box 11 , chain box 12, control pipeline 13, power pipeline 14, it is characterized in that: described walking trolley 2 front and rear two all are arranged on chain hoist 6, described walking trolley 2 and chain hoist 6 are connected by connecting shaft 10; The inner side of the trolley 2 is provided with a wheel 5, and the wheel 5 is suspended on the guide rail 1; the chain hoist 6 is a steel plate welded integral structure, and the two ends of the chain hoist 6 are provided with joint bearings 26 and safety lugs 15, The chain hoist 6 includes a sprocket shaft 21, a sprocket wheel 28, a primary passive gear 19, a primary driving ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com