Synthetic method of decahydronaphthalene

A synthesis method and technology of decahydronaphthalene, applied in the field of chemical engineering, can solve problems such as high energy consumption, high reaction pressure, and large equipment investment, and achieve reduction of reaction pressure, improvement of reaction safety, reduction of equipment investment and reaction energy consumption small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

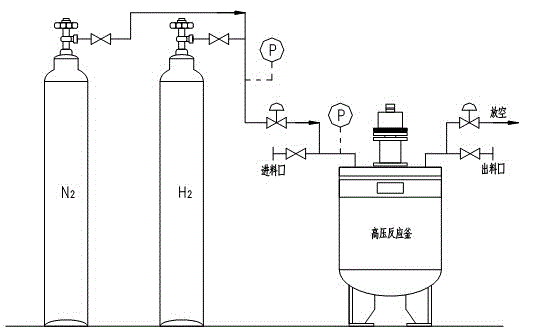

Method used

Image

Examples

Embodiment 1

[0035] Add 50 grams of naphthalene, 150 grams of tetrahydronaphthalene, and 50 grams of platinum-molybdenum catalyst into a high-pressure stirred reactor. Under the conditions of reaction temperature 160°C and reaction pressure 2 MPa, the liquid hourly volume space velocity (LHSV) is 0.5, and the single-pass conversion rate of naphthalene up to 99.5%, decahydronaphthalene selectivity up to 99.5%, decahydronaphthalene yield up to 99.0%.

Embodiment 2

[0037] Add 50 grams of naphthalene, 150 grams of tetrahydronaphthalene and 50 grams of platinum-molybdenum catalyst into the high-pressure stirred reactor. Under the conditions of reaction temperature 160 ° C and reaction pressure 1 MPa, the liquid hourly volume space velocity (LHSV) is 0.5, and the single-pass conversion rate of naphthalene The decahydronaphthalene selectivity reaches 99.2%, the decahydronaphthalene selectivity reaches 99.5%, and the decahydronaphthalene yield reaches 98.7%.

Embodiment 3

[0039] Add 50 grams of naphthalene, 150 grams of tetrahydronaphthalene, and 50 grams of platinum-molybdenum catalyst into a high-pressure stirred reactor. Under the conditions of reaction temperature 180 ° C and reaction pressure 0.5 MPa, the liquid hourly volume space velocity (LHSV) is 0.5, and the one-way conversion of naphthalene The rate reaches 99.1%, the decahydronaphthalene selectivity reaches 99.5%, and the decahydronaphthalene yield reaches 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com