Anti-freezing hydrogen and oxygen generator

A technology for generating machine, hydrogen and oxygen, applied in the direction of electrodes, cells, electrolysis process, etc., can solve problems such as high freezing point, decreased gas production efficiency, and inability to carry out electrolysis reaction, so as to avoid the effect of electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] The aforementioned and other technical content, features and effects of the present invention will be clearly understood in the following detailed description of a preferred embodiment with reference to the drawings.

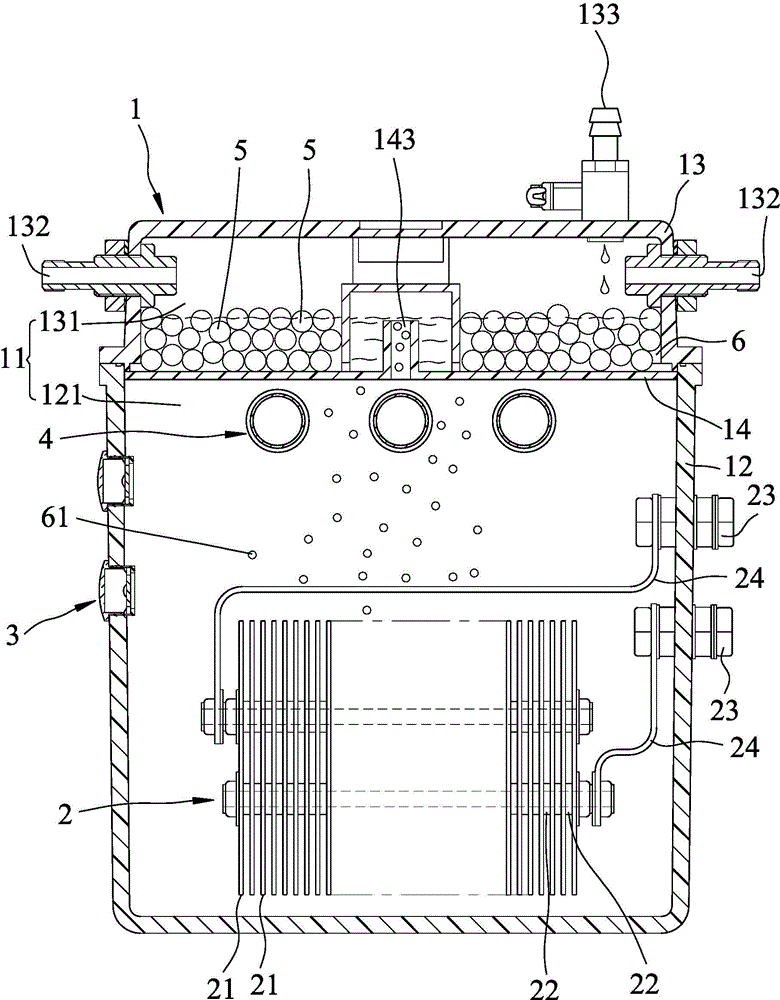

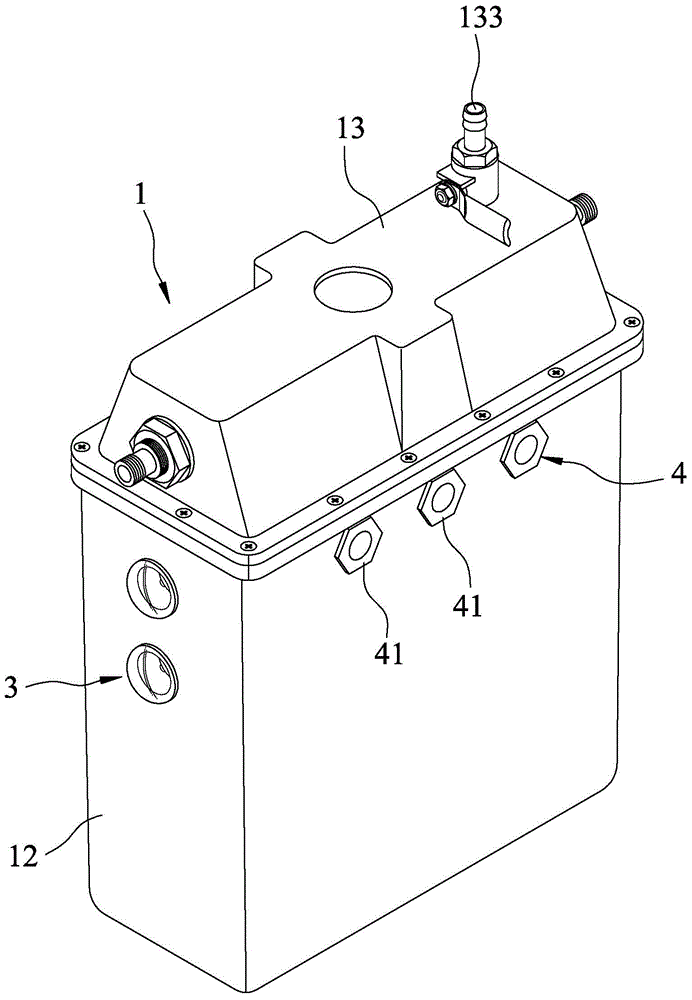

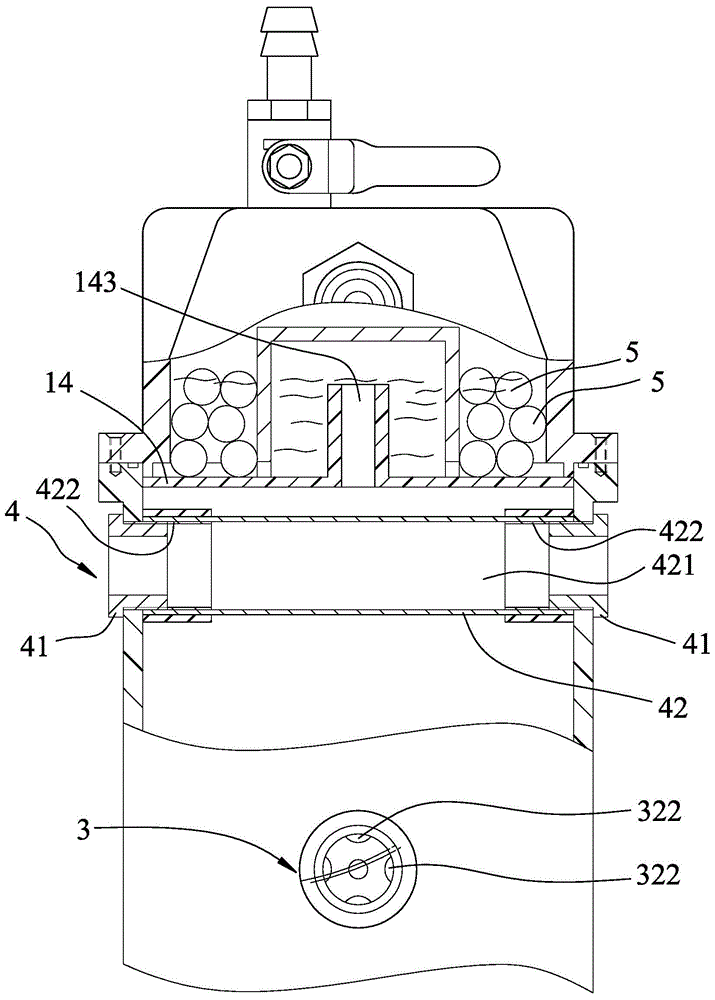

[0021] refer to Figure 1 to Figure 3 , the preferred embodiment of the antifreeze hydrogen oxygen generator of the present invention is suitable for holding a working liquid 6, and includes a housing unit 1, an electrode unit 2, at least one window unit 3, at least one heat dissipation unit 4, and a plurality of Antifreeze particles5. In this embodiment, the working fluid 6 is water.

[0022] The housing unit 1 surrounds and forms a main chamber 11 for accommodating the working liquid 6, and includes an electrolytic cell 12, a cover body 13 that is arranged on the top of the electrolytic cell 12, and a piece that is arranged b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap