Floor-heating solid wood floor board

A geothermal floor and solid wood technology, which is applied to floors, buildings, building structures, etc., can solve the problems of high difficulty in wood processing, lower floor heights, unbalanced forces, etc., to prevent deformation due to heat and moisture, increase floors, and damage force balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

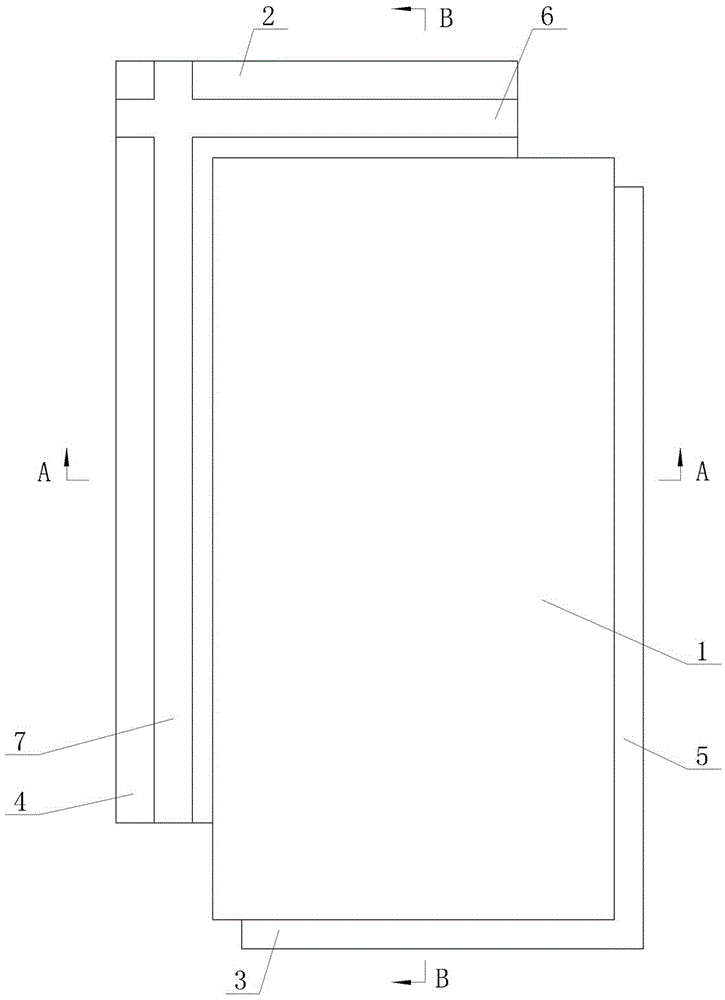

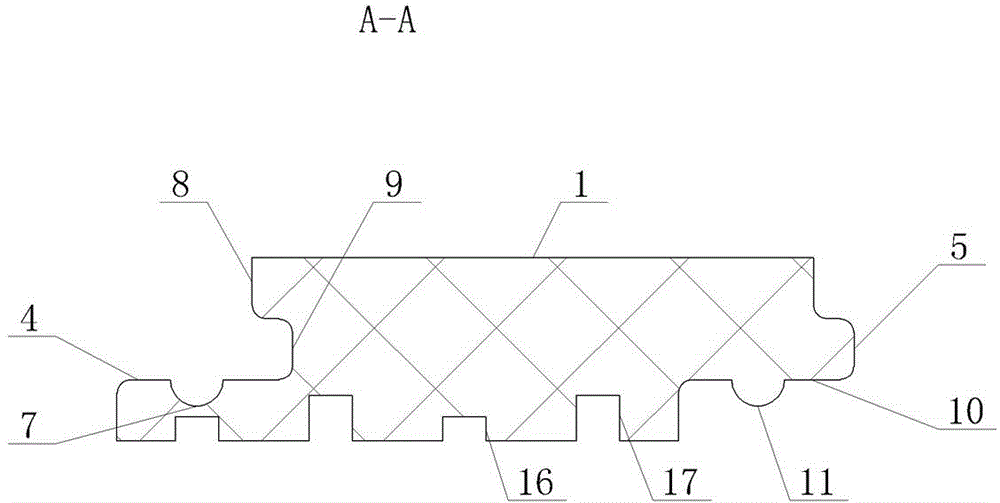

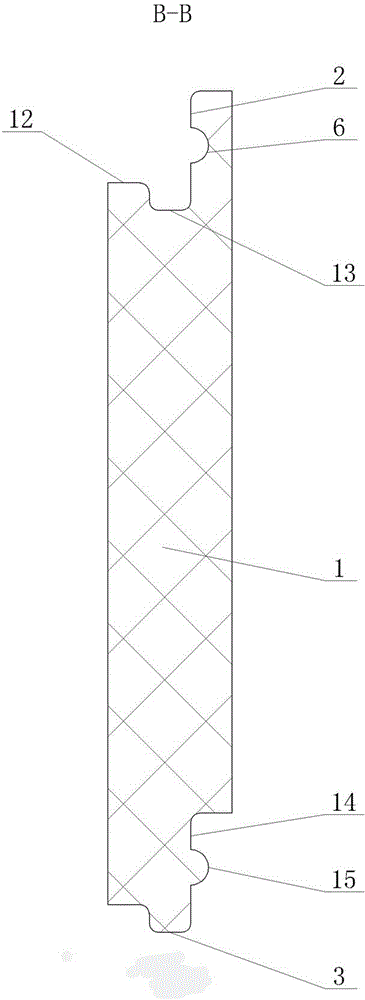

[0009] The present invention includes a base plate 1, the base plate 1 is in the shape of a cuboid, and every two adjacent side walls of the four side walls of the base plate 1 form a group, which are divided into two groups. The flashboard 2 and the second flashboard 4 are provided with a first baffle plate 12 and a second baffle plate 8 on the upper parts of the two side walls respectively. A first positioning groove 6 and a second positioning groove 7 are provided in the length direction of the flashboard 4, a first groove 13 is formed between the first baffle plate 12 and the first flashboard 2, and the second baffle plate 8 and the second flashboard 4 The second groove 9 is formed between them; the two side walls of the other group of the substrate 1 are respectively provided with a first bump 3 corresponding to the first groove 13 and a second bump 5 corresponding to the second groove 9, and The first slot 14 corresponding to the first plug board 2 and the second slot 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com