Underground gasification well cementing method and well structure

A technology of underground gasification and well structure, applied in the direction of coal gasification, underground mining, drilling equipment and methods, etc., can solve problems such as casing fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

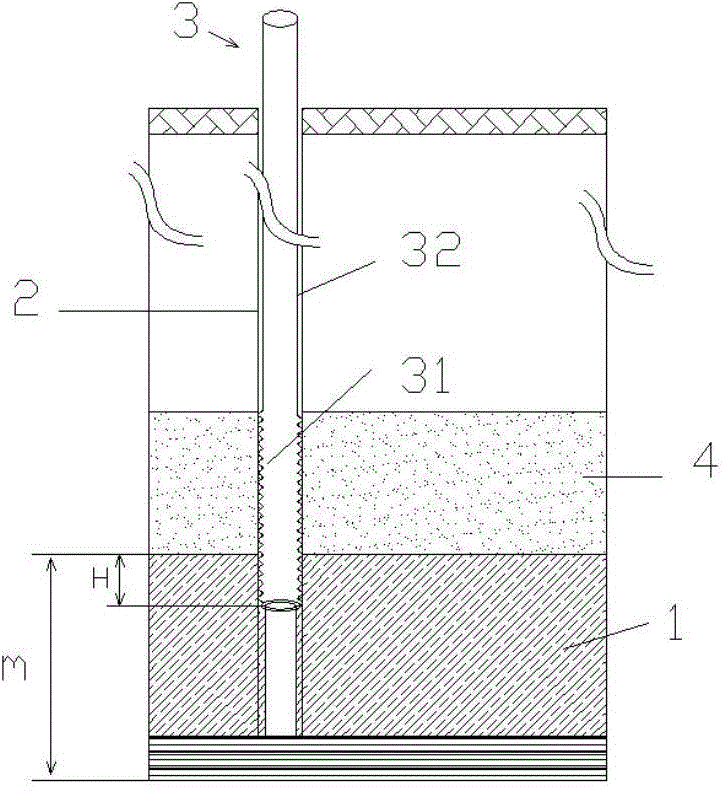

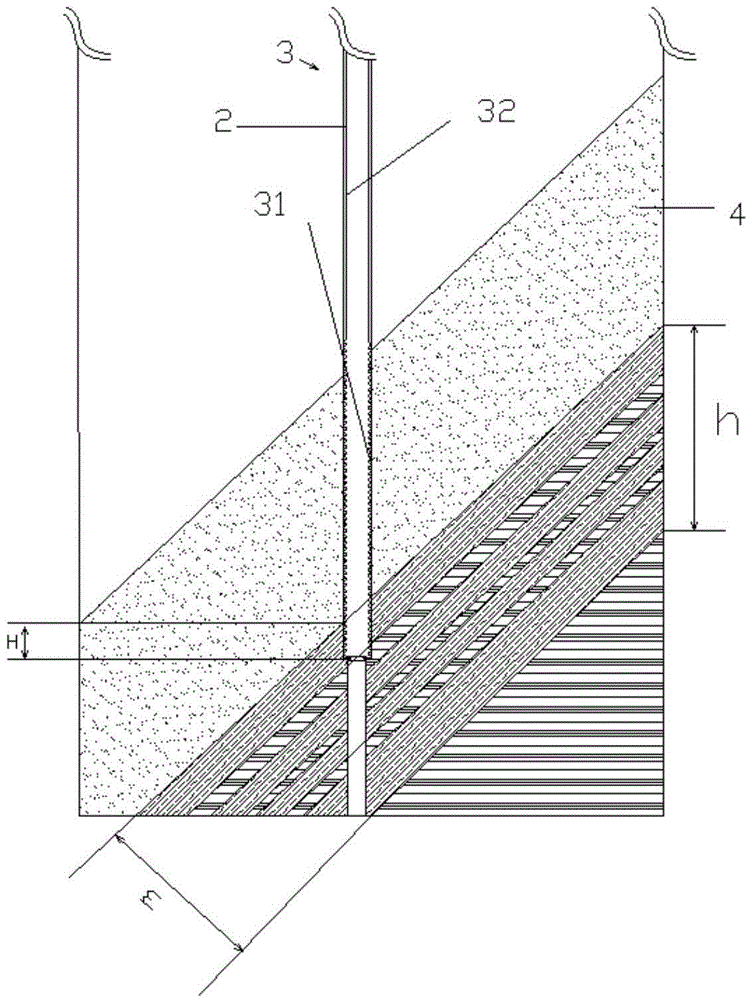

[0021] Embodiments of the present invention are described below with reference to the drawings.

[0022] see figure 1 In this embodiment, an embodiment of the underground gasification cementing method of the present invention is provided, which is used for the gasification of underground coal seams.

[0023] In the method of this embodiment, during the construction process of the well 2 leading into the coal seam 1 from the ground, or after the construction is completed, the following step of setting the cementing casing 3 is performed: the cementing casing 3 is lowered into the well 2 until the cementing casing 3 is set. The bottom end of the well casing 3 enters the coal seam 1 to a set depth and stops, and the cementing casing 3 is connected to the well wall of the well 2 . Wherein, the cementing casing 3 at least includes a telescopic flexible casing 31, the bottom end of the telescopic flexible casing 31 constitutes the bottom end of the cementing casing 3, and the lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com