Novel exhaust ejection postprocessor

A post-processor and exhaust gas technology, applied in exhaust devices, machines/engines, mufflers, etc., can solve the problems of catalysts failing to meet requirements, affecting treatment effects, and indirect exhaust emissions, achieving simple structure and improving conversion efficiency. , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

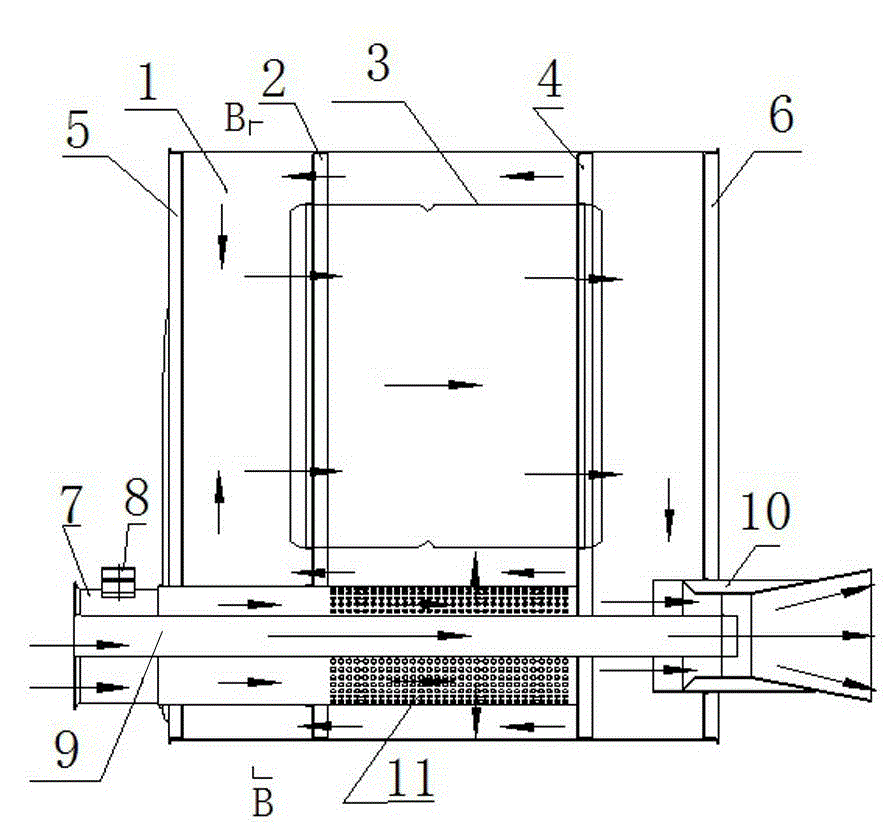

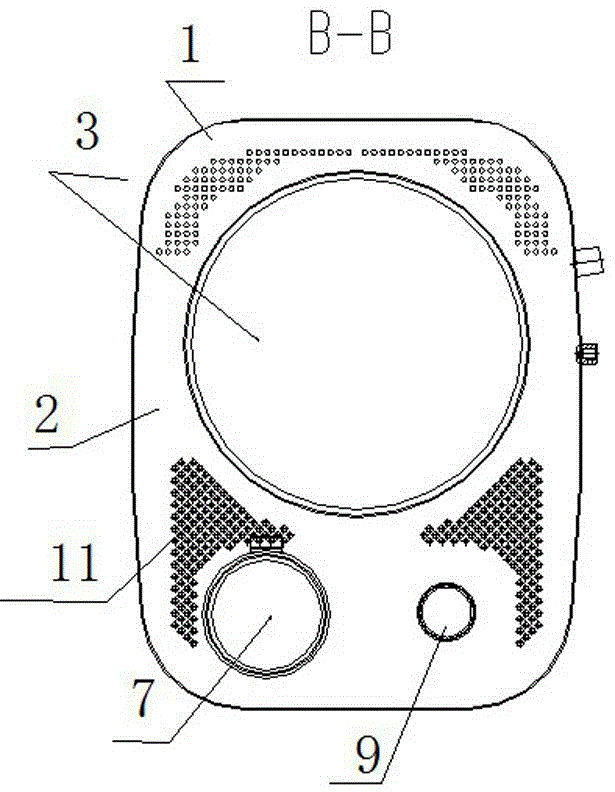

[0015] The invention as figure 1 , 2 shown.

[0016] A new type of exhaust gas injection post-processor, including a cylinder 1, the cylinder 1 is divided into three chambers by the front and rear end covers 5, the first partition 2 and the second partition 4, and the first partition 2 and the second partition 4 There is a carrier assembly 3 between them, and a plurality of small holes 11 are uniformly arranged on the first partition 2, and the air inlet port 7 passes through the front end cover 5 and the first chamber to the second chamber and is docked with the second partition 4 , the air inlet pipe 5 is evenly provided with a plurality of small holes 11 on the pipe wall in the second chamber; the air outlet terminal 10 is arranged on the rear end cover 6, and an ejector pipe 9 is arranged in the air outlet end 10, and the ejector pipe The other end of 9 passes through from dividing plate two 4, the second chamber, dividing plate one 2, front end cover 5 successively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com