Transient fuel control method for air inlet passage injection type gasoline engine

A fuel control and gasoline engine technology, applied in fuel injection control, electrical control, engine control, etc., can solve the problems of large memory resource consumption, insufficient consideration of parameters, poor real-time performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

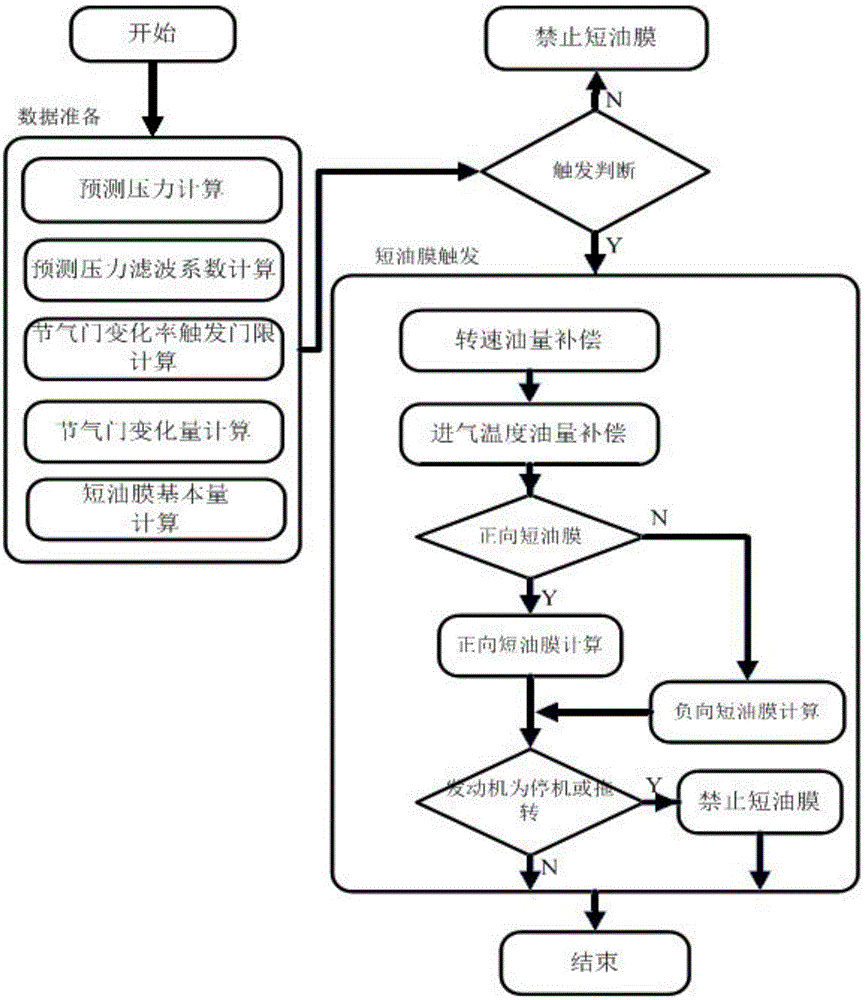

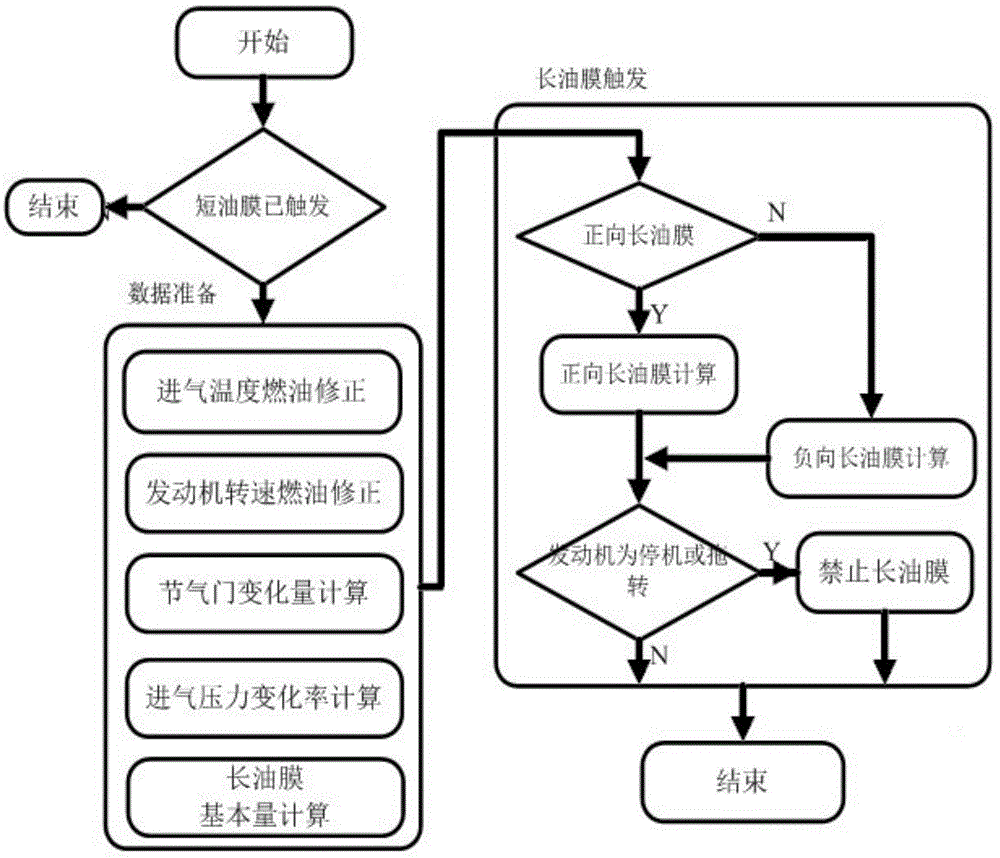

[0050] The transient fuel oil control method described in the present invention can be classified into two types: short oil film control and long oil film control. Among them, the short oil film is used to compensate the instantaneous large amount of oil film loss caused by the sudden change of the throttle valve, and the long oil film is used to compensate the oil film loss caused by the increase of the intake pressure. The long oil film lasts for a long time, and the process of its attenuation to zero is the process of the oil film reaching the evaporation-deposition equilibrium.

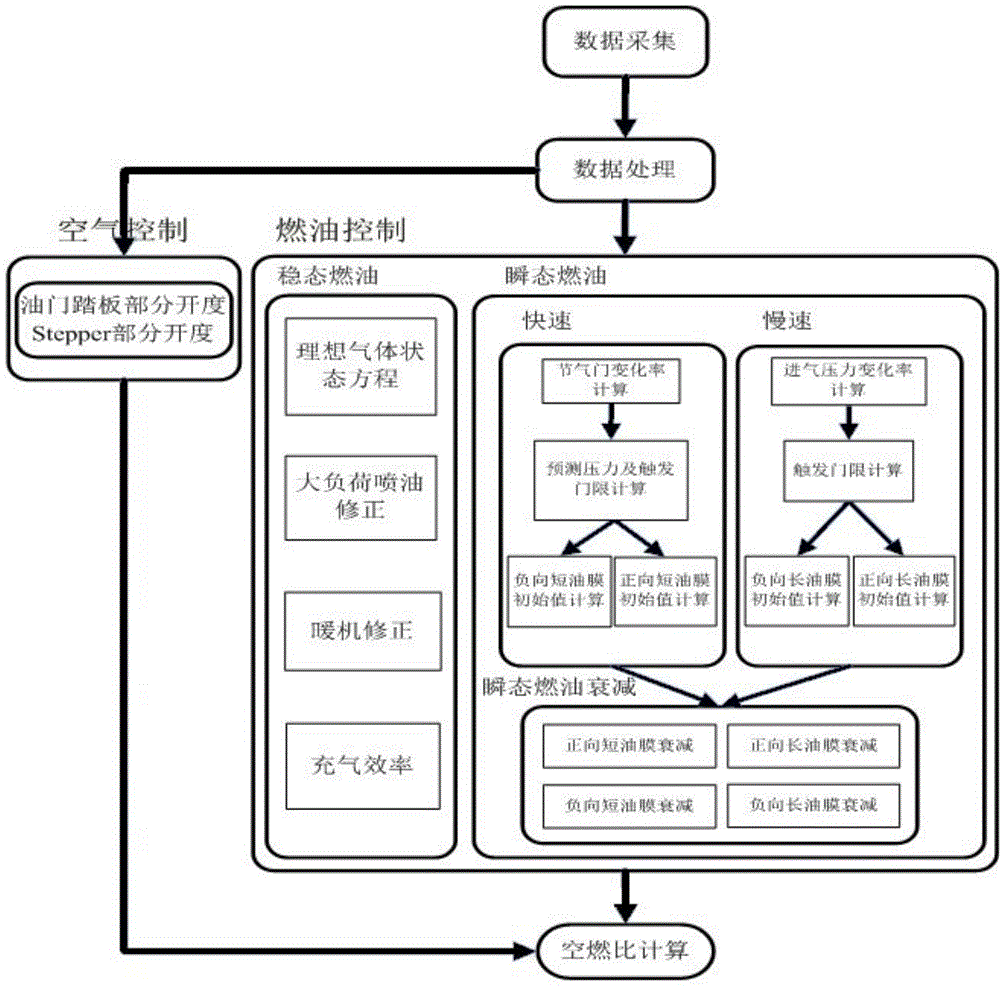

[0051] figure 1 It is a schematic diagram of the air-fuel ratio model, which can be roughly divided into five parts: data acquisition, data processing, gas circuit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com