Air distribution mechanism with concave shaft

A concave shaft valve mechanism and concave shaft technology, applied in exhaust devices, mechanical equipment, engine components, etc., can solve the problems affecting the engine compression ratio and complex structure, and achieve the effect of increasing the compression ratio and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

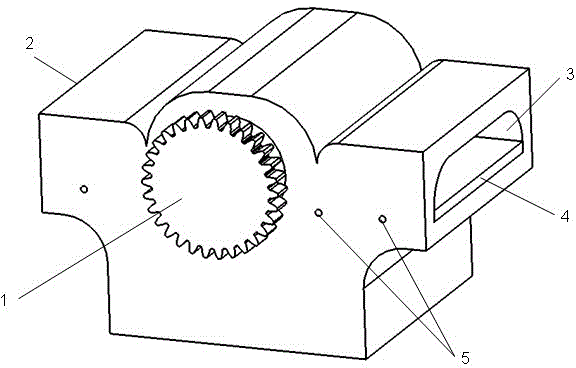

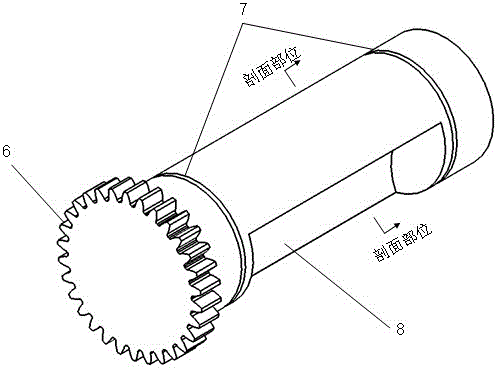

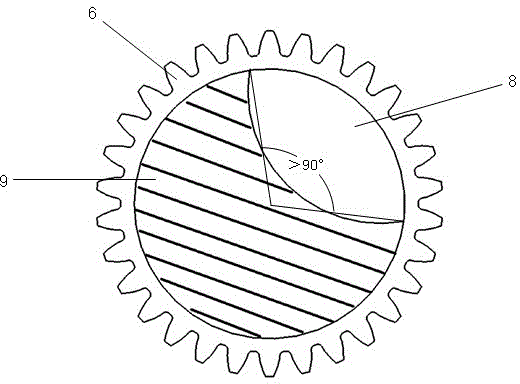

[0021] The concave shaft valve mechanism of the present invention will be further explained below in conjunction with the accompanying drawings.

[0022] The side of the concave shaft gas distribution cylinder head with spark plug is the intake channel, and the other side is the exhaust channel. The concave shaft through hole and the shrapnel positioning pin hole of the cylinder head are processed in the direction perpendicular to the front and rear. A positioning seal ring groove is processed on the through hole, a rectangular gas main passage is processed between the cylinder head concave shaft through hole and the cylinder, and the spark plug is installed on one side of the gas main passage; the concave shaft is a solid cylinder, A timing gear is welded at one end, and a concave channel is processed on one side of the shaft. On the profile of the concave shaft, the angle formed by the line connecting the concave channel and the center of the concave shaft is greater than 90 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com