Automatic driving shaft sealing magnetic pump

A technology of automatic sealing and driving shaft, which is applied in the direction of pumps, pump control, pump components, etc., to achieve the effects of improving operation safety and reliability, convenient manufacturing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

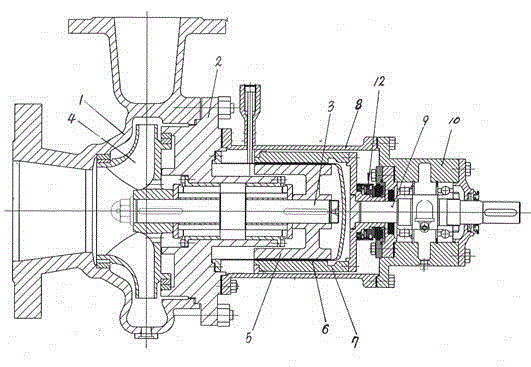

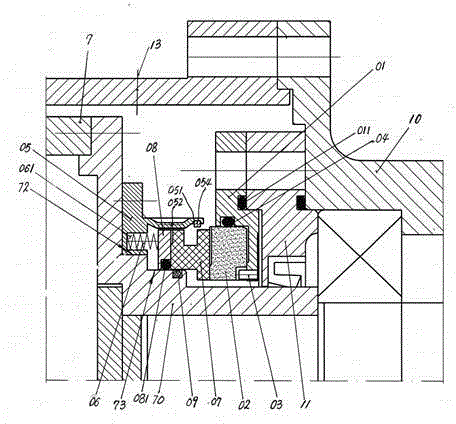

[0015] As shown in the accompanying drawings, the dry gas mechanical seal device 12 consists of a static ring seat 01, a static ring 02, a static ring anti-rotation pin 03, a static ring seal ring 04, a spring seat 05, a spring 06, a moving ring 07, and a spring retainer Ring 08, dynamic ring sealing ring 09;

[0016] On the gland 11 of the bearing box 10, there is a spigot platform, and the static ring seat 01 cooperates with the notch of the bearing box gland 11 and is fixedly connected with the bearing box gland 11 through screws. There is a sealing ring 011 on the mating surface;

[0017] The static ring 02 is installed in the spigot groove on the static ring seat 01, and the static ring sealing ring 04 is arranged between the outer ring surface of the static ring 02 and the static ring seat 01, and the static ring 02 rear side end surface and the static ring seat 01 There is an anti-rotation pin 03 between them;

[0018] A first seam 72 is provided on the sleeve portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com