Under-vehicle lightweight bottom cover plate and welding method thereof

A bottom cover and bottom plate technology, applied in welding equipment, welding/welding/cutting items, railway car bodies, etc., can solve problems such as increased fatigue load, rivet fatigue fracture, rivet loss, etc., to achieve high welding quality and prevent deformation , Improve the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

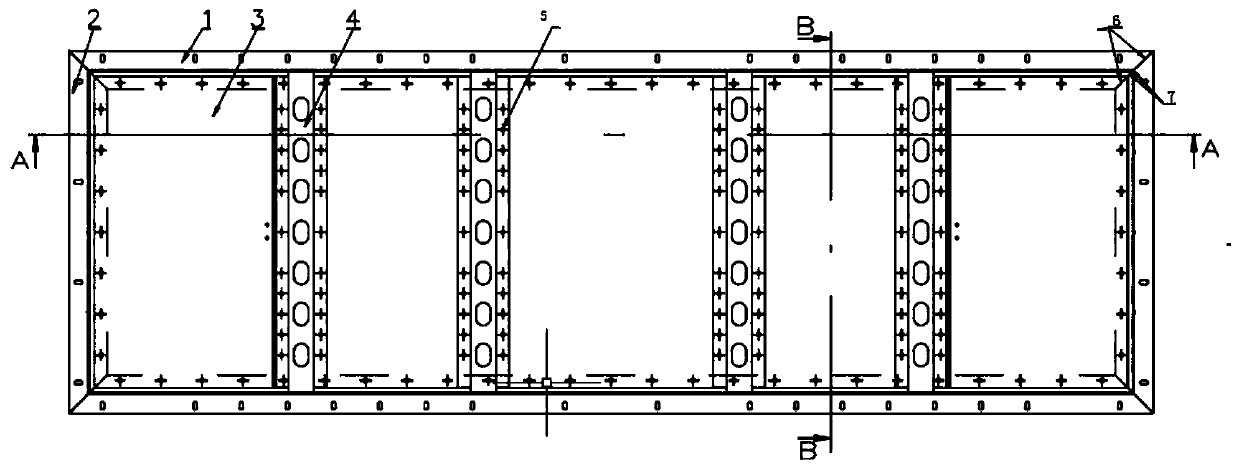

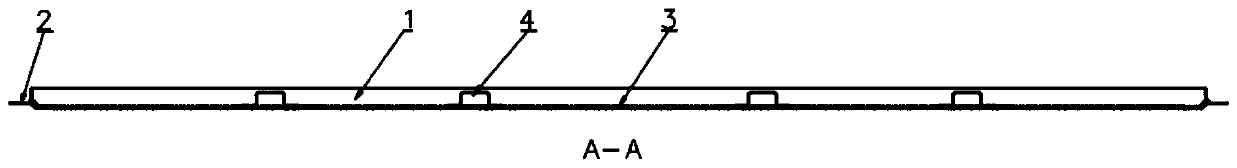

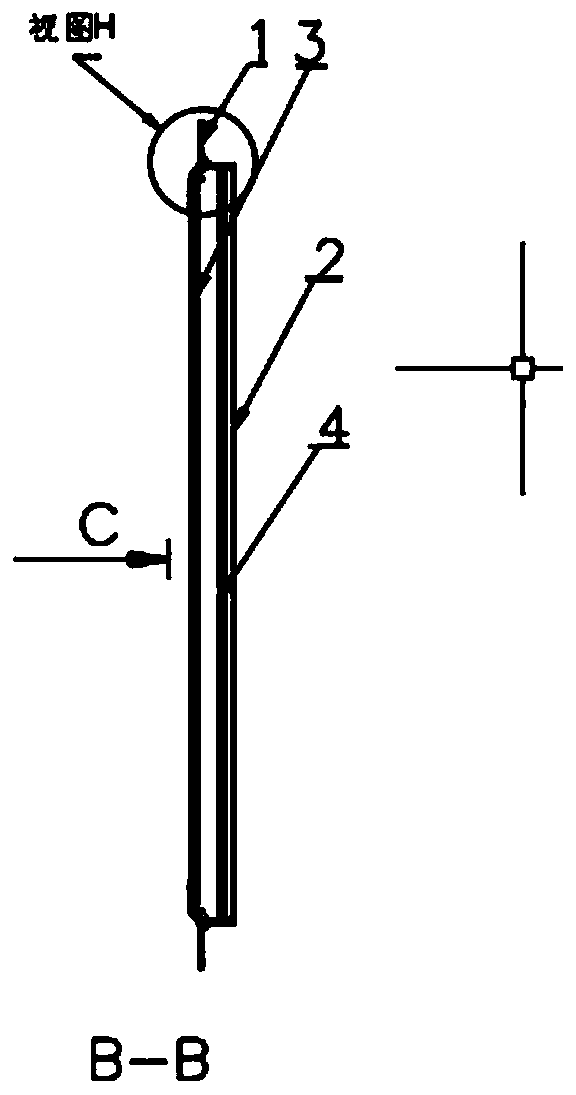

[0032] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0033] like Figure 1-12 As shown, an underbody cover plate includes an underbody cover plate body, the underbody cover plate body includes an aluminum alloy base plate 3 and an aluminum cover plate frame, the aluminum cover plate frame is set as an aluminum profile frame, The aluminum profile frame is welded by the first aluminum profile 1 and the second aluminum profile 2, the aluminum alloy base plate 3 is provided with aluminum profile reinforcing ribs, the thickness of the aluminum profile frame and the aluminum alloy base plate 3 are both 3 mm, so The thickness of the reinforcing rib 4 of the aluminum profile is 2mm;

[0034] Based on the structure of the lightweight bottom cover under the vehicle, the present invention also provides a welding method for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com