Anti-corrosion chimney and installation and construction method thereof

A technology for anti-corrosion and chimney, which is applied in the direction of combustion method, exhaust gas device, combustion product treatment, etc. It can solve the problems of hidden dangers in the safe operation of chimneys, difficult construction, high material cost, etc., to solve the problem of corrosion leakage and shorten the construction period. Short, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

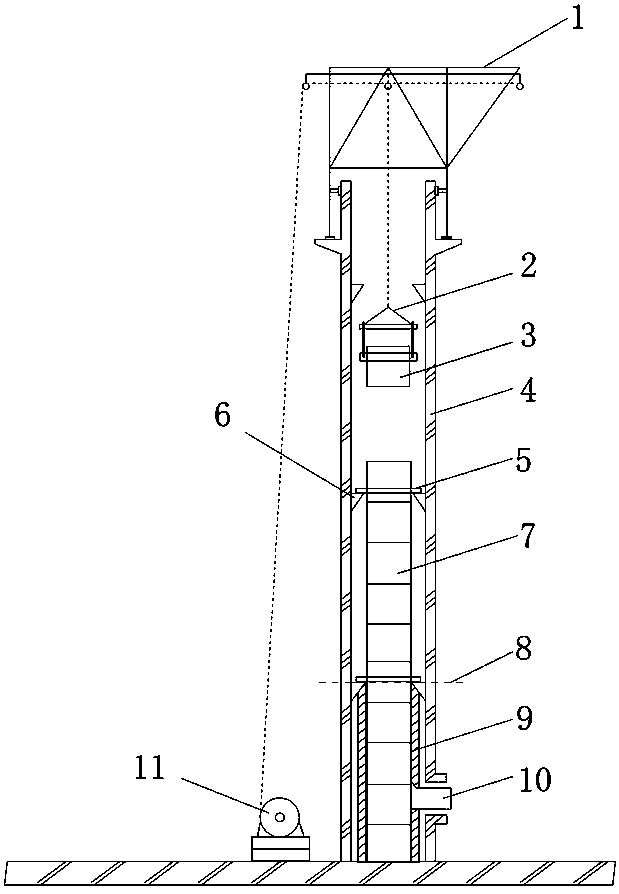

[0021] An anti-corrosion chimney and its installation and construction method. In the inner cylinder part of the chimney above the 26.5m elevation, a glass fiber reinforced plastic inner cylinder 7 is installed, and the glass fiber reinforced plastic inner cylinder is made in sections, each section is 5-7m, and each section is hoisted and spliced in sequence, and the joint is manual. Paste process; Imported ceramic vitrified bricks are added to the chimney steel inner cylinder and horizontal flue below the 26.5m elevation to form a ceramic vitrified brick sleeve 9; imported glue can also be applied instead to form a sleeve-type FRP inner cylinder structure.

[0022] The specific installation and construction procedures are as follows:

[0023] 1. Remove the steel inner cylinder and anti-corrosion lining that have lost their anti-corrosion function, repair the defects of the chimney accessories, and then install the fiberglass inner cylinder inside the concrete chimney and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com