Double-intelligent flexible beam device based on driving and oscillating of planetary reducer

A technology of planetary reducer and flexible beam, which is applied in the field of double intelligent flexible beam device driven by planetary reducer. The effect of large transmission speed ratio and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

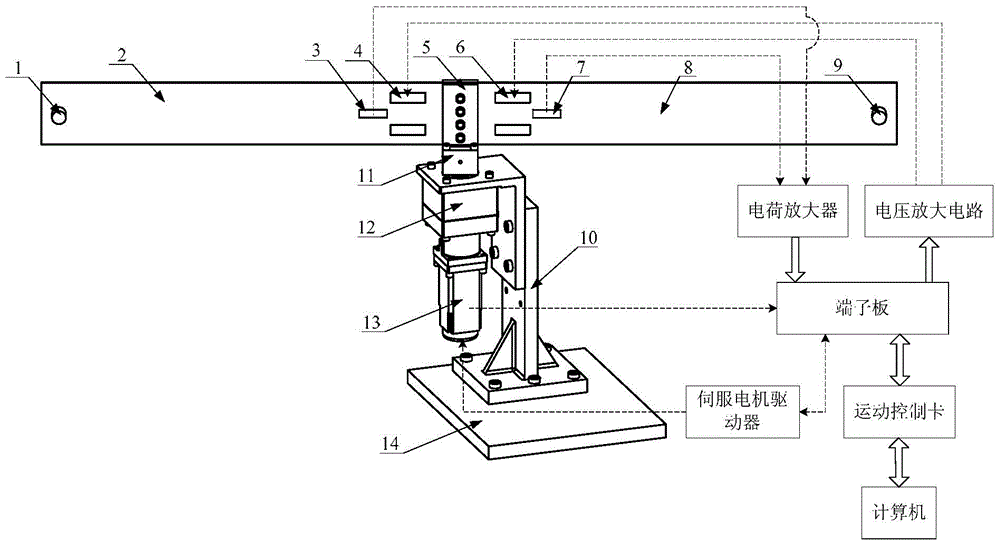

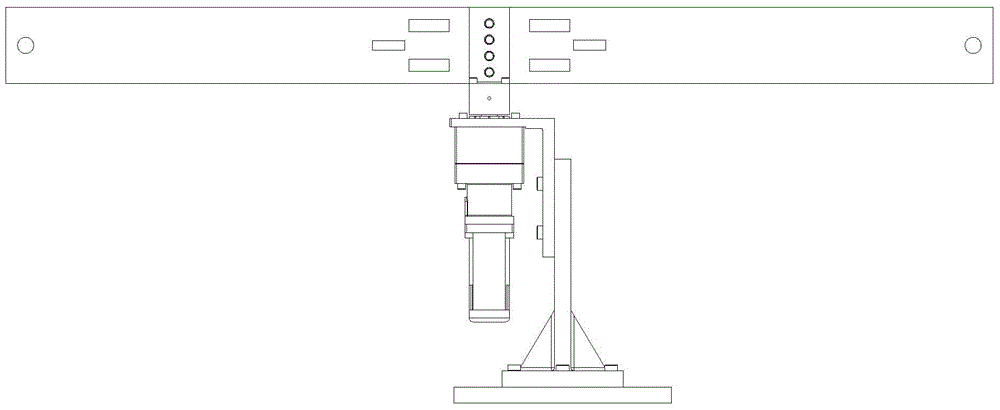

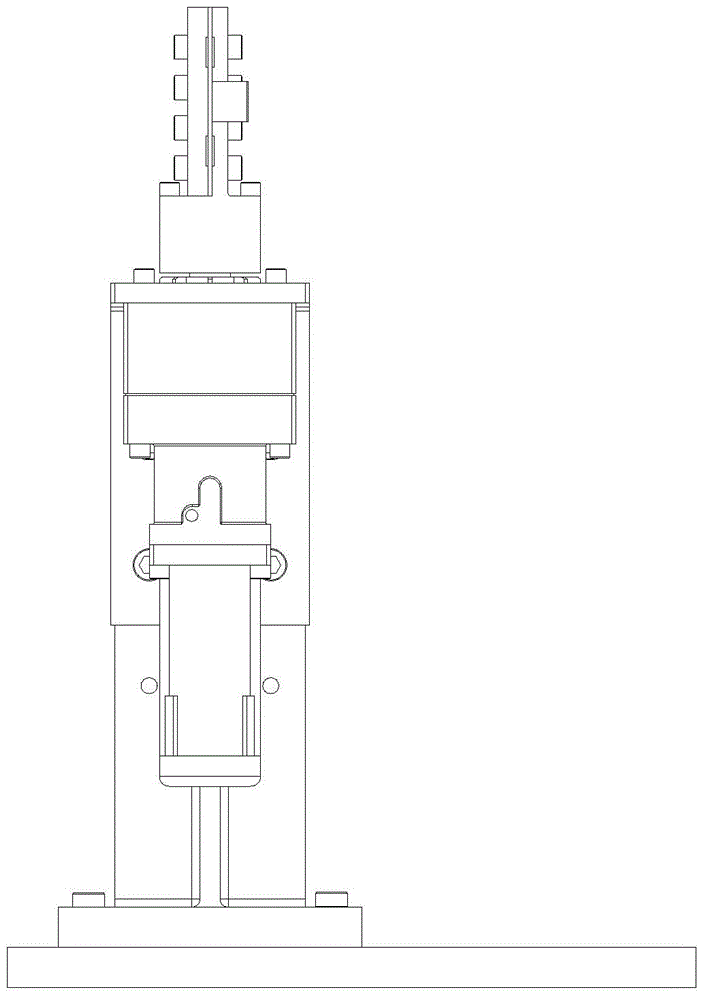

[0036] Such as Figure 1-Figure 5 As shown, a double intelligent flexible beam device driven by a planetary reducer, including

[0037] The first flexible beam 2 has one end as a free end and the other end as a fixed end; the second flexible beam 8 has one end as a free end and the other end as a fixed end, and the fixed ends of the first and second flexible beams pass through the wheels The socket 11 and the splint 5 are installed on the output shaft of the planetary reducer 12, so that the first flexible beam 2 and the second flexible beam 8 can rotate horizontally around the output shaft of the planetary reducer 12, and the planetary reducer 12 is fixed on On the fixed bracket 10, the fixed bracket 10 is installed on the base 14 so that its output shaft can rotate around the vertical axis, the planetary reducer 12 and the servo motor 13 are connected for driving, and the servo motor driver converts the control signal sent by the computer into a drive The signal of the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com