Bilateral fitting confocal measuring method

A measurement method and confocal technology, applied in measurement devices, instruments, optical devices, etc., can solve the problem of confocal microscope resolution limitation and other problems, and achieve improved axial resolution, improved signal-to-noise ratio, and high signal-to-noise ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

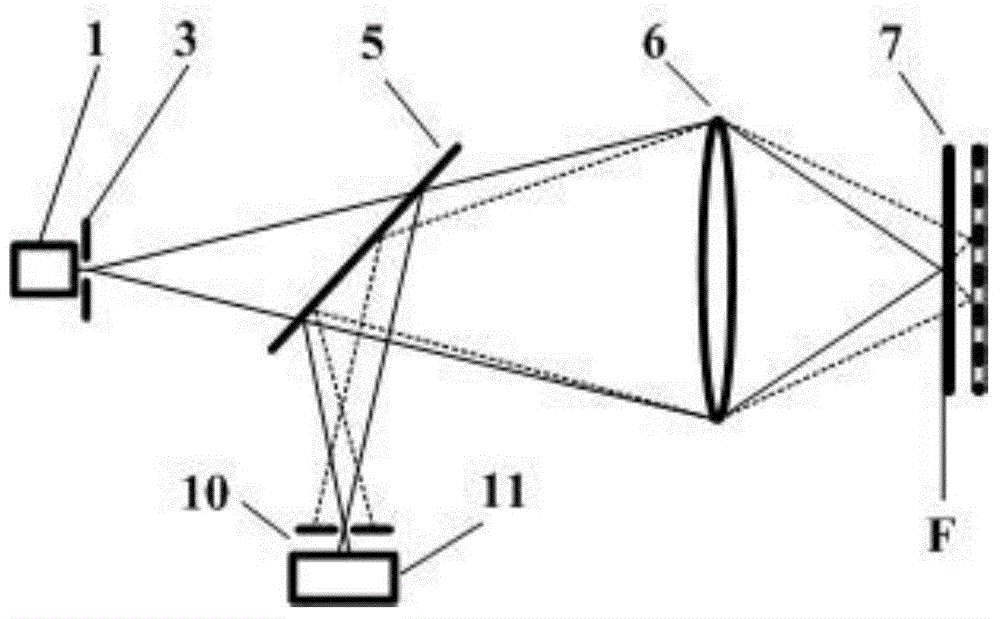

[0036] Combination of specific steps for carrying out single-point height value fitting measurement using the method of the present invention Figure 5 described as follows:

[0037] Step 1. Select a certain measurement point N(x,y) on the sample 7, make the objective lens 6 focus the light spot to scan the measurement point axially, and at the same time, the photodetector detection 11 detects the confocal axial intensity of the axial position of the sample The response value is 14, denoted as I(z), where x, y and z are the coordinates of the horizontal position and the axial height position of the sample measurement point respectively;

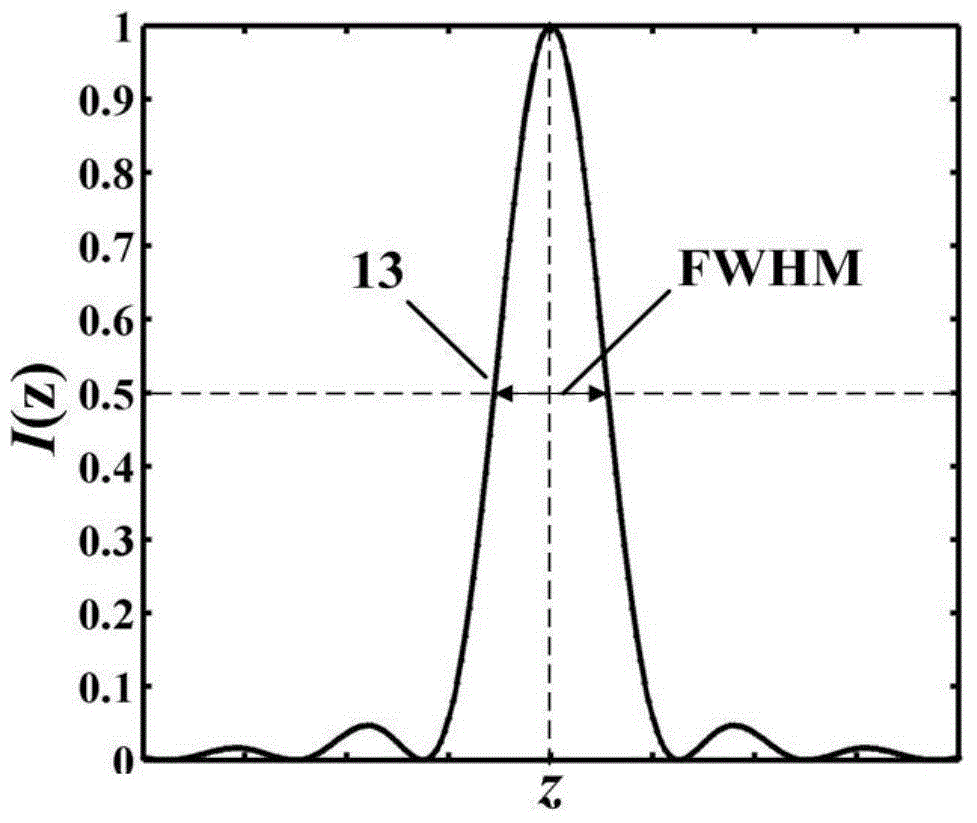

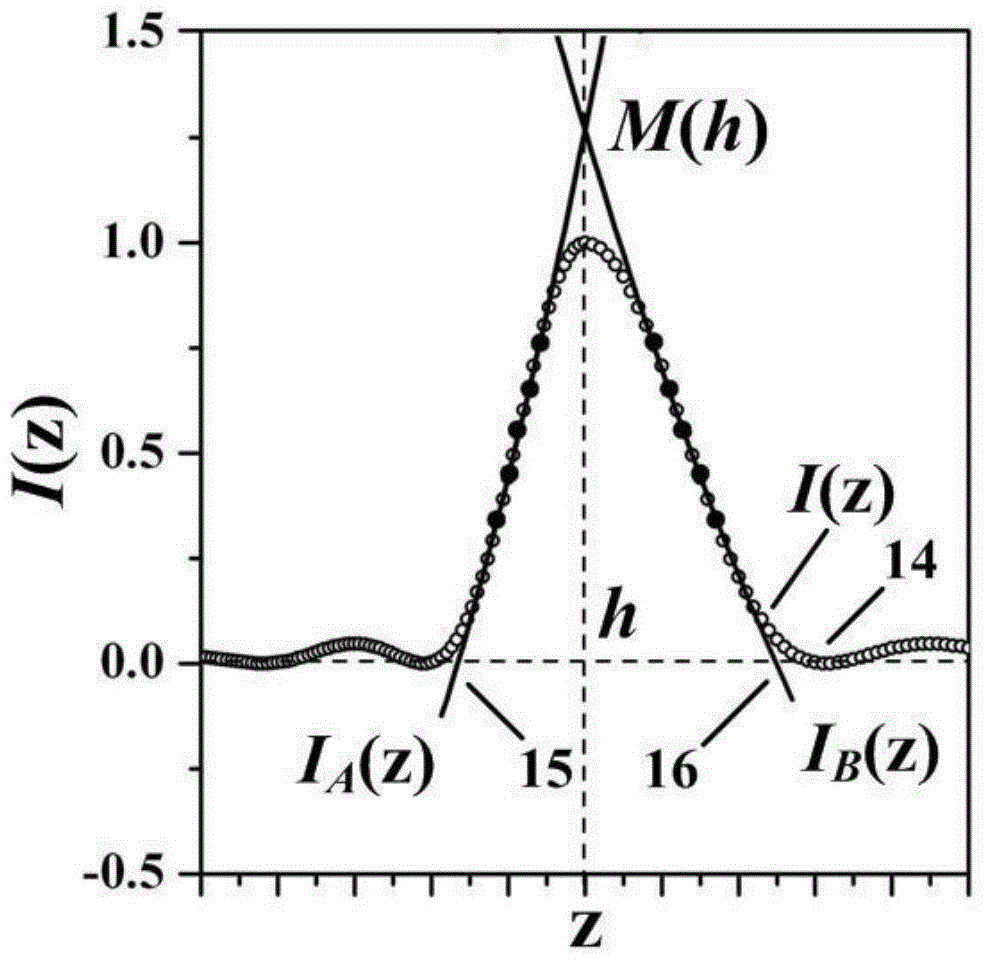

[0038] Step two, such as Figure 4 As shown, find the maximum value M of the confocal axial intensity response value 14;

[0039] Step three, such as Figure 4 As shown, on both sides of the confocal axial intensity response data, the data point whose intensity is M / 2 point is used as a reference point to select a data segment near it;

...

Embodiment 2

[0044] Under the scanning of the sample workbench, the method of the present invention is used to combine the measurement steps of point-by-point tomographic scanning imaging Figure 5 described as follows:

[0045] Step 1, move the workbench 8, write down the horizontal position coordinates N(x, y) of the measured point of the sample 7;

[0046] Step 2: Feed the objective lens 6 in axial steps relative to the sample 7 along the optical axis, and the photodetector 11 measures the confocal axial intensity response value 14 corresponding to each axial feeding position;

[0047] Step three, such as Image 6 As shown, use the computer measurement and control system 12 to extract the maximum value point position M corresponding to the measured interface in the sequence photoelectric signal value measured in step 2 k ;

[0048] Step 4, such as Image 6 As shown, take a section of data points at the positions where the steepness changes on both sides of each maximum point obtaine...

Embodiment 3

[0054] Under the scanning of the sample workbench, the measurement steps of layer-by-layer scanning tomography using the method of the present invention are combined Figure 5 described as follows:

[0055] Step 1. Focus the objective lens 6 on the first interface of the sample to be tested, and then move the workbench 8. In this interface, the photodetector 11 measures the photoelectric signal values of all the points to be measured, and simultaneously records the levels of all points to be measured. Position coordinates;

[0056] Step 2. According to the measurement accuracy requirements of the sample, select the micro-feeding step of the objective lens relative to the sample;

[0057] Step 3: Feed the objective lens 6 relative to the sample 7 in small steps along the direction of the optical axis, and then accurately move the worktable 8 according to the coordinates of the horizontal position points recorded in step 1, so that the focal spot of the objective lens is alig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com