FBG (fiber bragg grating)-based multifunctional flow sensor provided with embedded standard nozzle

A technology of flow sensor and optical fiber grating, which is applied in the field of multifunctional flow sensor, fiber grating embedded standard nozzle multifunctional flow sensor, can solve the problems of optical fiber grating temperature strain cross sensitivity, etc., to facilitate assembly, improve efficiency and yield , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

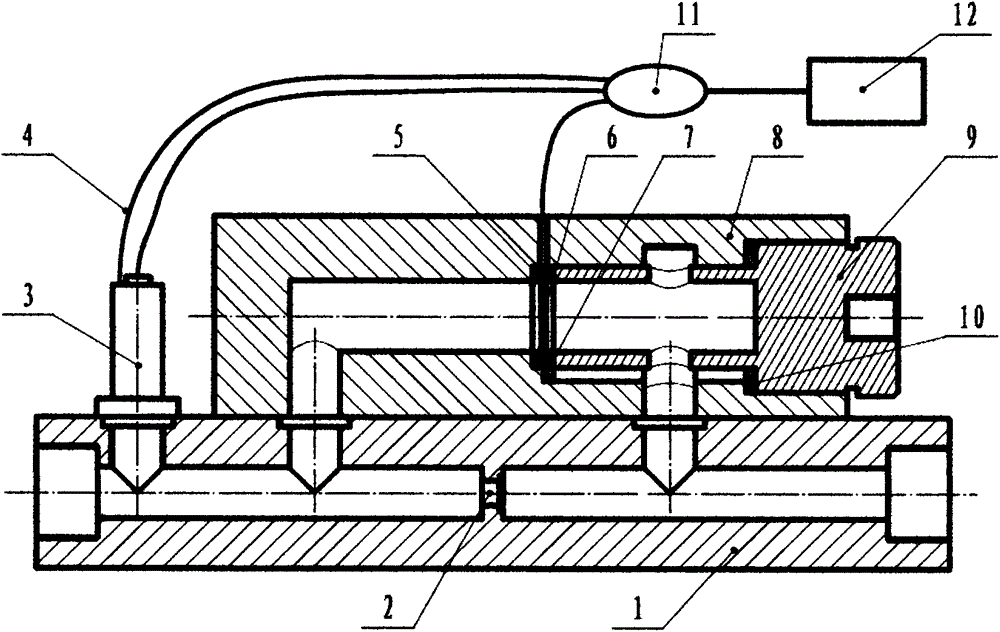

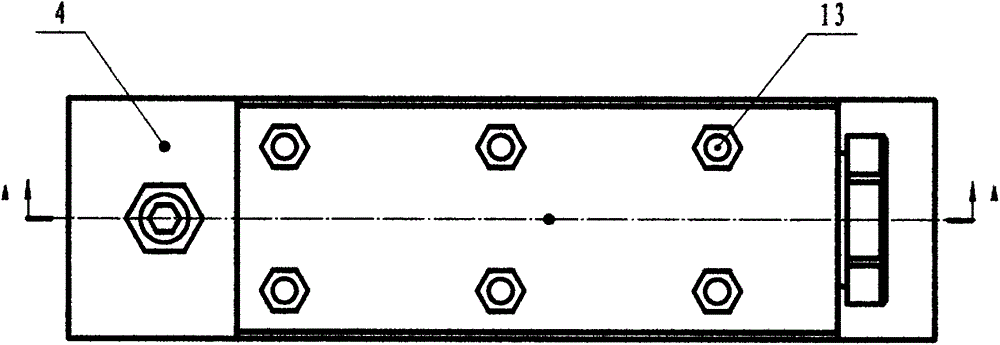

[0016] The structural principles and specific implementation methods of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 and figure 2 As shown, a fiber grating-based embedded standard nozzle multifunctional flow sensor, including the main valve body (1) and the ISA1932 standard nozzle (2) embedded in it, when the measured fluid flows through the ISA1932 standard nozzle (2) When , a pressure difference corresponding to the mathematical relationship with the flow is generated. The fluid to be measured is respectively introduced into the pressure taking cavity (8) through the pressure taking holes at the front and back of the ISA1932 standard nozzle (2). And the pressure difference acts on the alloy diaphragm (6) bonded with the optical fiber grating, and the deformation of the alloy diaphragm (6) will cause the change of the reflected wavelength of the optical fiber grating center.

[0018] Similar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com