Testing device for measuring cold-state flow field in gas burner based on PIV (particle image velocimetry) technique

A gas burner and test device technology, applied in the field of test devices based on PIV technology, can solve problems such as doubts about the reliability and accuracy of calculation results, inability to fully learn from PIV measurement devices, and the like, and achieve the effect of avoiding disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The test device designed according to the present invention takes an in-service air-staged gas burner as a prototype, processes it into a model burner with plexiglass at a ratio of 1:4 (model: prototype), and builds and measures the formation speed of the model burner in a cuboid combustion chamber. Field-specific test equipment. This embodiment is designed based on the principle of simulating a non-isothermal process with an isothermal medium, and mainly studies the influence of different nozzle structures on the shape of the flow field.

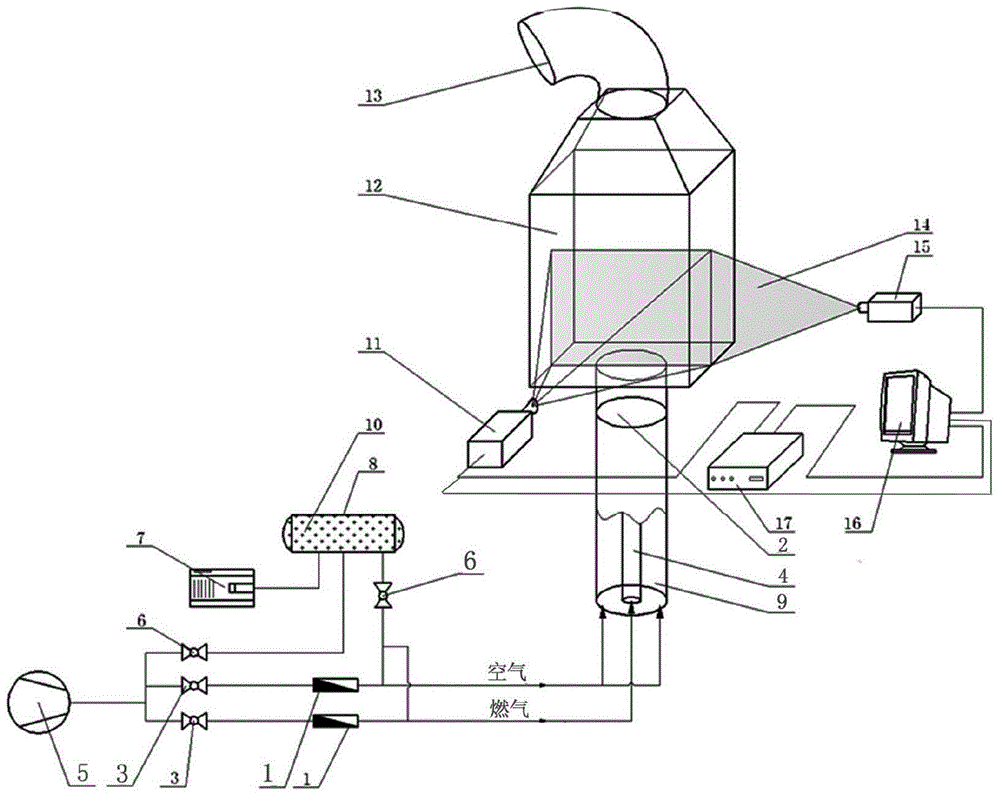

[0040] see figure 1, the test device of this embodiment, including a cold model of a heating furnace, a gas path system, a tracer particle dispersion device and a PIV test system. The cold state model of the heating furnace includes a burner 2 , a transparent combustion chamber 12 and a smoke exhaust pipe 13 , one end of the burner 2 is connected with the transparent combustion chamber 12 , and the upper part of the transparent com...

Embodiment 2

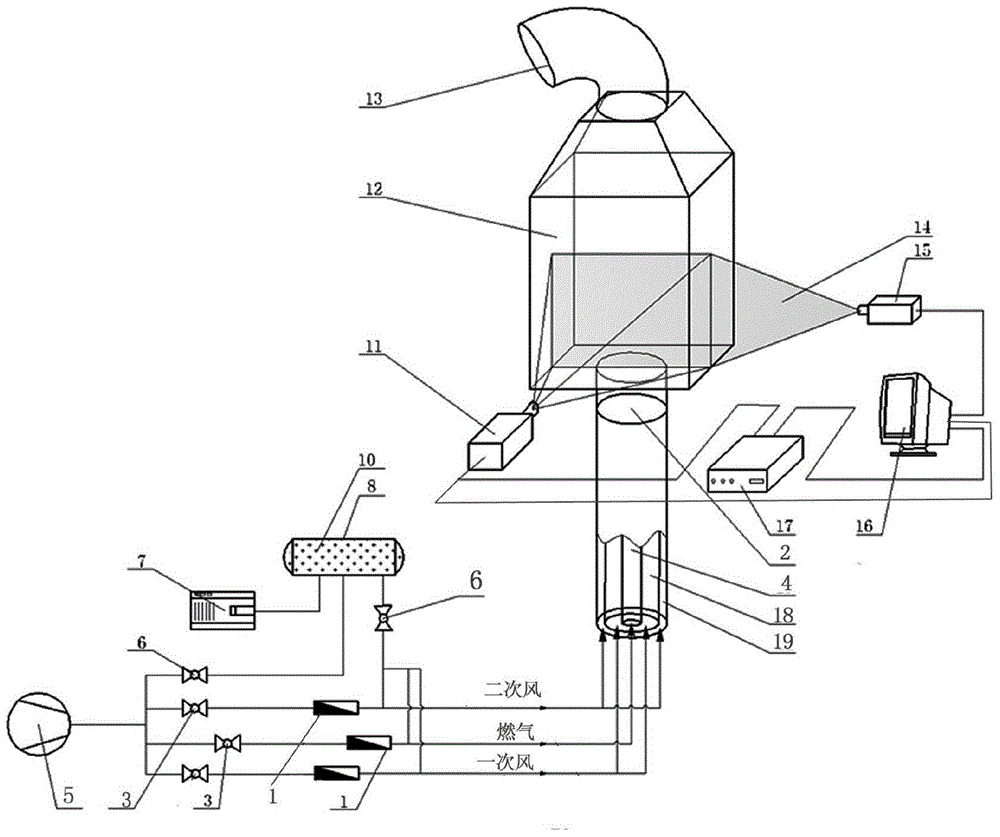

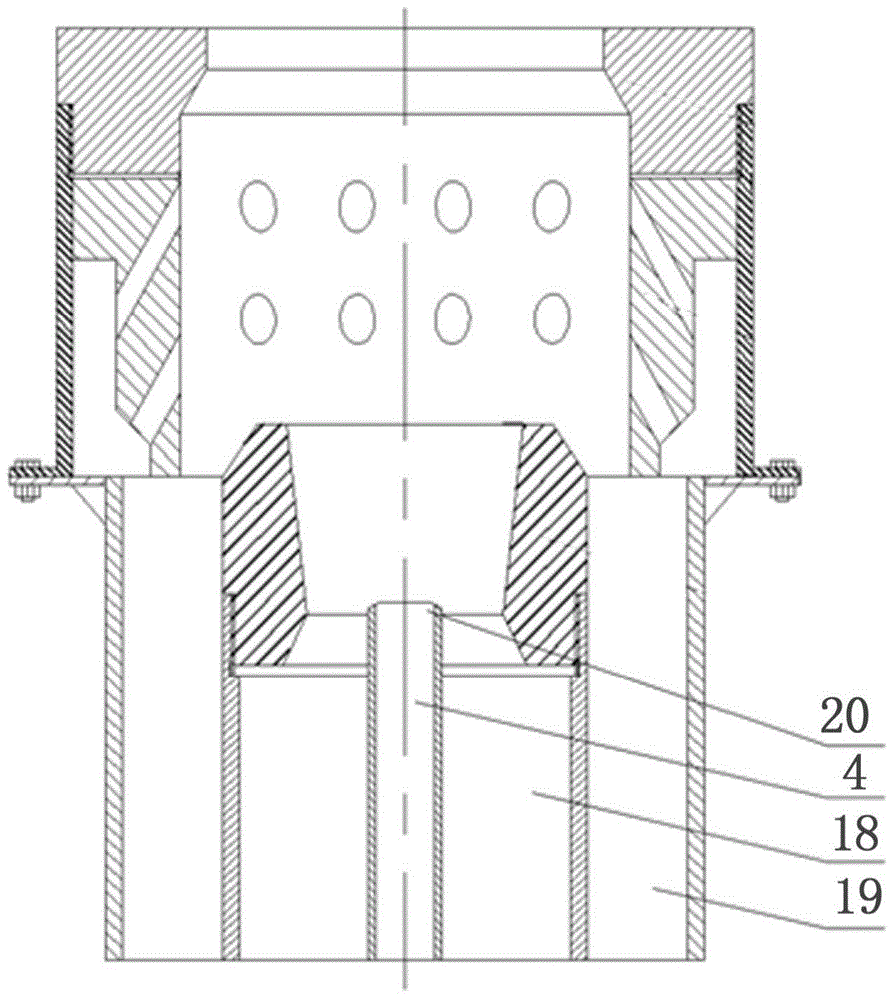

[0046] see figure 2 , the device in this embodiment is basically the same as that in Embodiment 1, the only difference is that the secondary air pipe 19 and the primary air pipe 18 are used to replace the air pipe in Embodiment 1, and the discharge port of the buffer tank 8 is connected to the primary air pipe. Tube 18 is connected. In this test device, the burner structure is shown in image 3 , the secondary air pipe 19, the primary air pipe 18 and the gas pipe 4 are coaxially nested and designed coaxially with the gas spray gun 20, and the dimensions are respectively Φ 160 × 7.5 mm, Φ 100 × 7.5 mm, Φ 20 × 3mm. The dimensions of the cuboid part of the transparent combustion chamber are 500 × 500 × 790 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com