Coal bed mining floor grouting infiltration-reducing simulation testing system

A technology of simulation test system and grouting system, which is applied in the field of grouting and seepage reduction simulation test system for coal seam mining floor, can solve the problems of providing less simulation environment, affecting the accuracy of test conclusions and on-site guidance, and avoiding corner effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

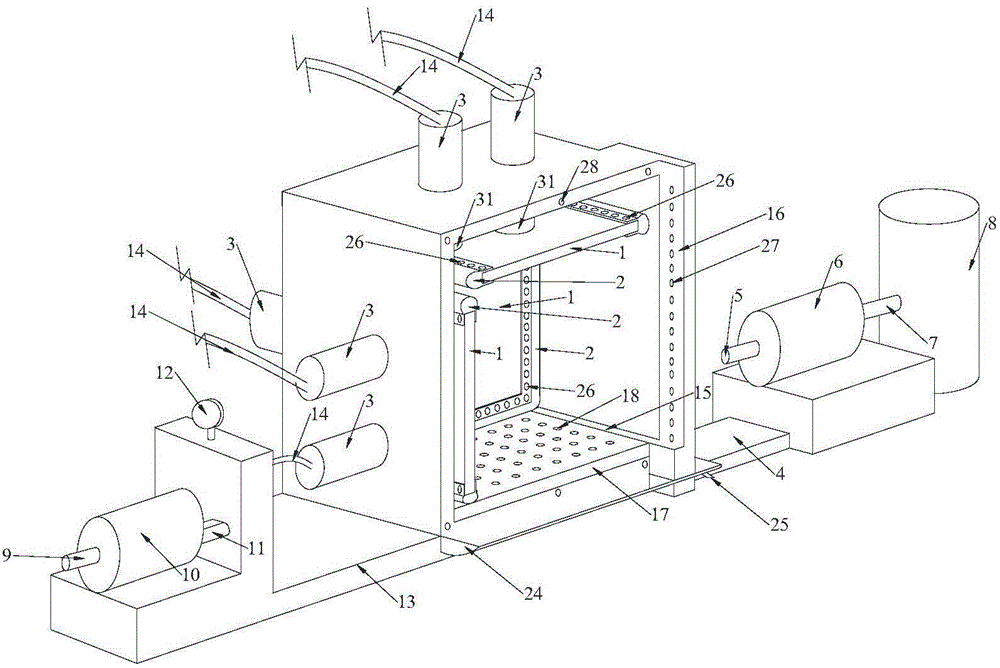

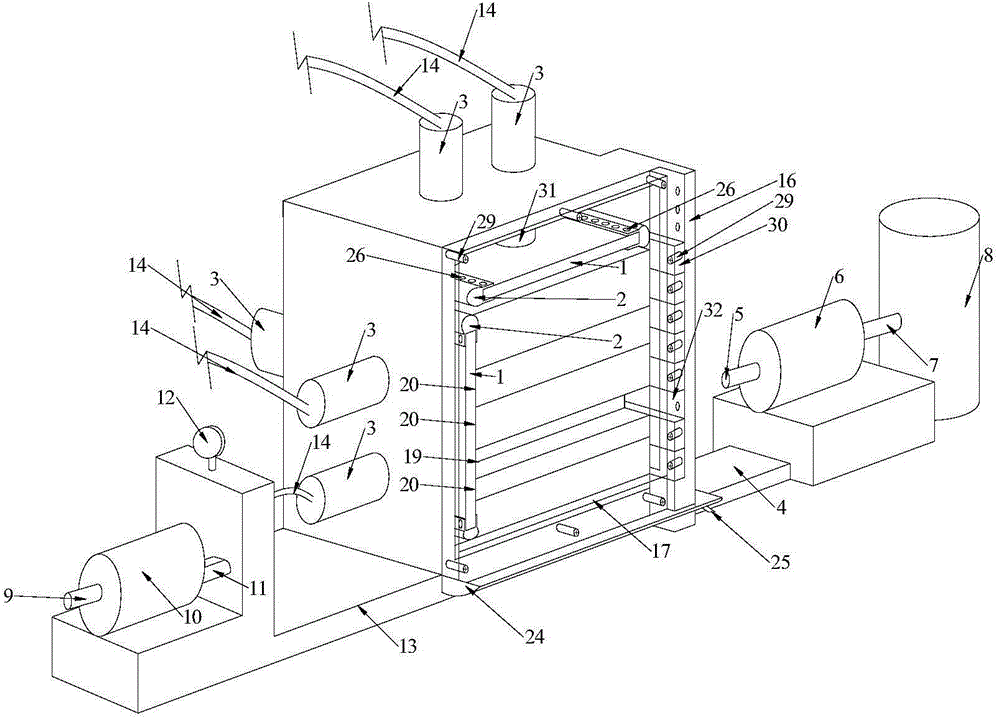

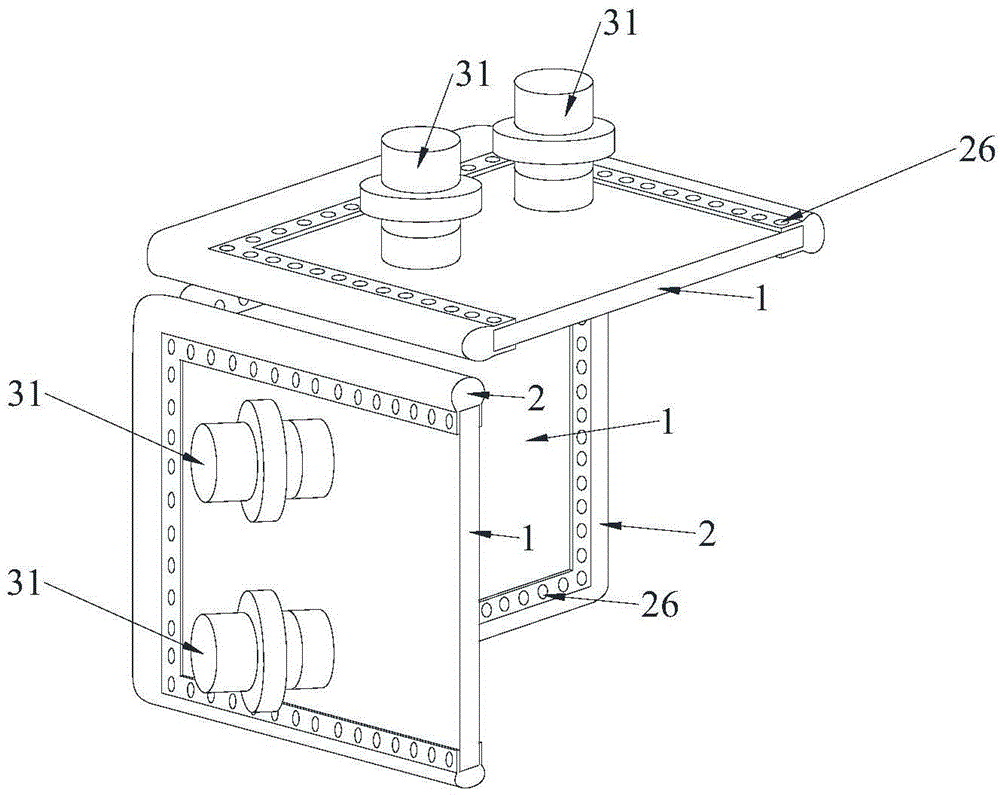

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] like Figure 1-Figure 6 As shown, a coal seam mining floor grouting seepage reduction simulation test system includes a test machine, the test machine has a pressure chamber inside, and also includes a grouting system and a hydraulic system. Described testing machine platform comprises the loading mechanism 3 that is arranged on X direction, Y direction and Z upwards of testing machine platform, and the telescopic shaft 31 of described loading mechanism 3 passes the outer wall of testing machine platform, and the inner end of described telescopic shaft 31 A pressure plate 1 is fixedly connected, and the edge of the pressure plate 1 is wrapped by a rubber edging strip 2 , and the rubber edging strip 2 is fixed on the pressure plate 1 by rubber fixing screws 26 .

[0029] The grouting system is connected with the test machine through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com