Test structure for Young's modulus of thick-film silicon material on insulating substrate

A technology for testing structures on an insulating substrate, applied in the direction of testing material strength by applying a stable bending force, can solve problems such as unstable measurement data accuracy, achieve stable test process and test parameter values, simple calculation methods, The effect of low test equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

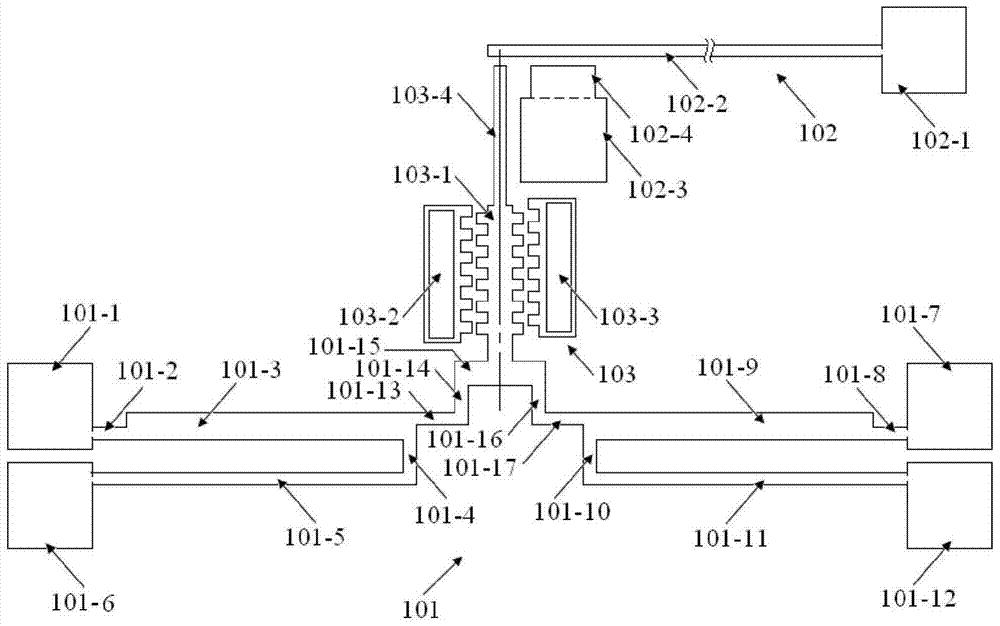

[0019] Attached below figure 1 The present invention will be further described.

[0020] The test structure consists of three parts: a relative electrothermal drive unit 101 ; a stopper unit 103 with a micrometer vernier; and an electrostatically driven cantilever beam unit 102 .

[0021] The relative electrothermal drive unit 101 is composed of two identical MEMS conventional electrothermal actuators connected oppositely. The MEMS electrothermal actuator on the left part consists of the first anchor area 101-1, the first thin beam 101-2, the first wide beam 101-3, the first connecting beam 101-4, the first thermal expansion thin beam 101-5, the first The six anchor zones 101-6 are connected clockwise. The MEMS electrothermal actuator on the right part is composed of the second anchor area 101-7, the second thin beam 101-8, the second wide beam 101-9, the second connecting beam 101-10, the second thermal expansion thin beam 101-11, the second Five anchor areas 101-12 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com