Multi-functional infrared gas sensor

A gas sensor, multi-functional technology, applied in the direction of instruments, scientific instruments, electric radiation detectors, etc., can solve the problems of low sensor integration, backward filter production process, complex production process, etc., to improve the detection rate and Response rate, high density and temperature drift, and the effect of reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

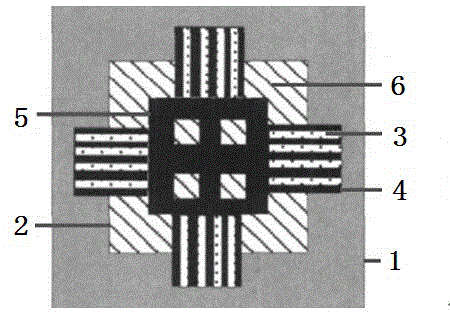

[0023] Such as figure 1 As shown, the multifunctional infrared gas sensor designed by the present invention includes an infrared characteristic filter and a thermopile 3 infrared detector, and the thermopile 3 infrared detector includes a plurality of sensing units, and each sensing unit includes a silicon substrate 1 , frame 2, thermopile 3, support arm 4, infrared absorbing layer 5 and etching opening 6, the center of silicon substrate 1 is provided with etching opening 6 through frame 2, and support arm 4 is provided on silicon substrate 1, and the interval between support arms 4 A thermopile 3 is provided, and the infrared absorbing layer 5 is suspended in the middle of the frame 2, and is fixedly connected to the frame 2 through the support arm 4. The silicon substrate 1 and the infrared absorbing layer 5 suspended in the middle of the frame 2 constitute the cold junction area and the thermopile 3 respectively. hot junction area.

[0024] The supporting arms 4 and the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com