Rock mass quality classification and dynamic parameter estimation method based on blasting vibration test

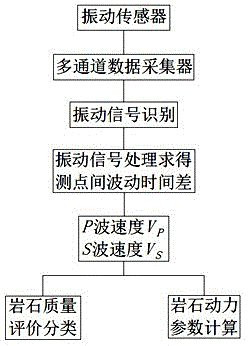

A technology for blasting vibration and rock mass quality, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve problems such as large differences in results, complicated operations, and difficulty in implementation, achieving reliable results, simple operations, and saving time and workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

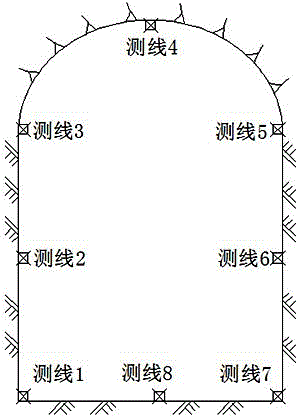

[0073] Cavern geological survey:

[0074] The blasting vibration detection sensor adopts a three-way vibration velocity sensor. During the detection process, each measuring point is equipped with a three-way vibration velocity sensor, which can measure vibration signals in the horizontal radial direction, horizontal tangential direction and vertical direction, and transmit the signals to the multi-channel data collector, and then input them into the computer for storage and analysis. Before the test starts, conduct a preliminary inspection of the object to be tested, and check the three-way vibration speed sensor and multi-channel data collector. The three-way vibration speed sensor is fixed on the measuring point with plaster.

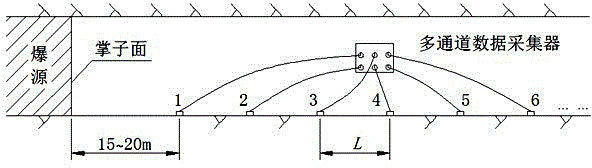

[0075] In this specific implementation, in order to prevent damage to the detection equipment (that is, three-way vibration velocity sensor and multi-channel data collector) during tunnel blasting, the first measuring point of each survey line (that ...

Embodiment 2

[0079] Slope geological survey:

[0080] The same detection equipment as in Example 1 was used. During the excavation process of slope blasting, seven measuring lines are arranged along different directions of the blasting source, as shown in Figure 4 As shown, each measuring line is arranged with multiple measuring points. In order to protect the safety of the detection equipment, the distance between the nearest measuring point and the explosion source on the same measuring line is 15-20m, and the distance between adjacent measuring points is 10-20m.

[0081] Using the same method as in Example 1 to process the blasting vibration signal, the propagation velocity of P wave and S wave between different measuring points during slope blasting excavation can be obtained, and the rock mass quality and dynamic parameters can be judged by the propagation velocity estimate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com