Optical adjustment structure

A technology of optical adjustment and adjustment parts, which is applied in the field of mechanical components, can solve problems such as complex optical adjustment structures, and achieve the effect of simple adjustment methods and effective structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

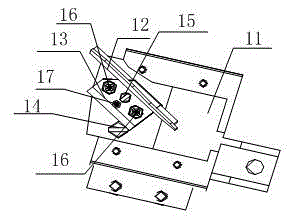

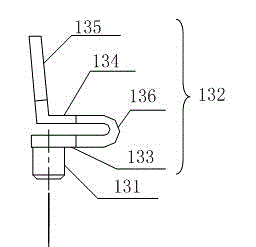

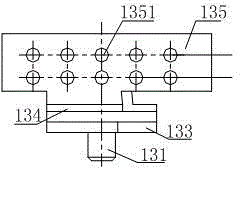

[0030] This embodiment provides an optical adjustment structure, such as Figure 1 to Figure 6 As shown, it includes a fixed frame 13 for installing the reflector 12. The fixed frame 13 is horizontally rotatably mounted on the base 11, and also includes a first adjusting member 14 for driving the fixed frame 13 to rotate horizontally on the base 11. An adjustment member 14 can rotate horizontally on the base 11 around the rotation axis, the outer surface of the first adjustment member 14 is arranged in contact with the side wall of the fixed frame 13, and along the horizontal rotation direction, the outer surface of the first adjustment member 14 is relative to the rotation axis The distance has a linear relationship.

[0031]The above technical solution is the core technical solution of the present invention, the fixed mount 13 is installed on the base 11 and can rotate horizontally on the base 11, the reflector 12 is installed on the fixed mount 13, and the rotation of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com