Optical proximity correction method

A technology of optical proximity correction and optical model, which is applied in the direction of optics, original components for photomechanical processing, instruments, etc., can solve problems such as unsatisfactory effects, achieve good effects and ensure physical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

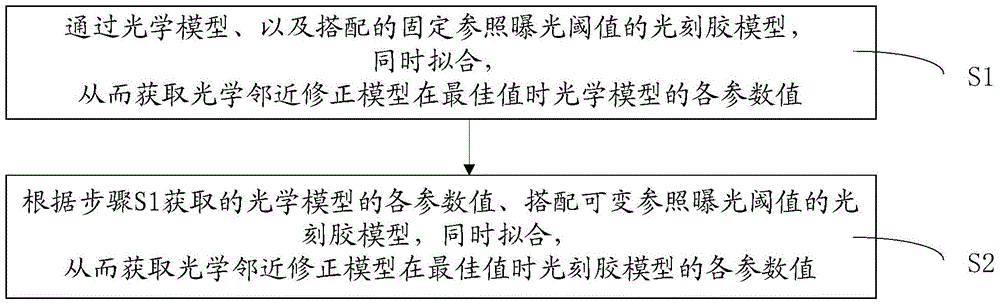

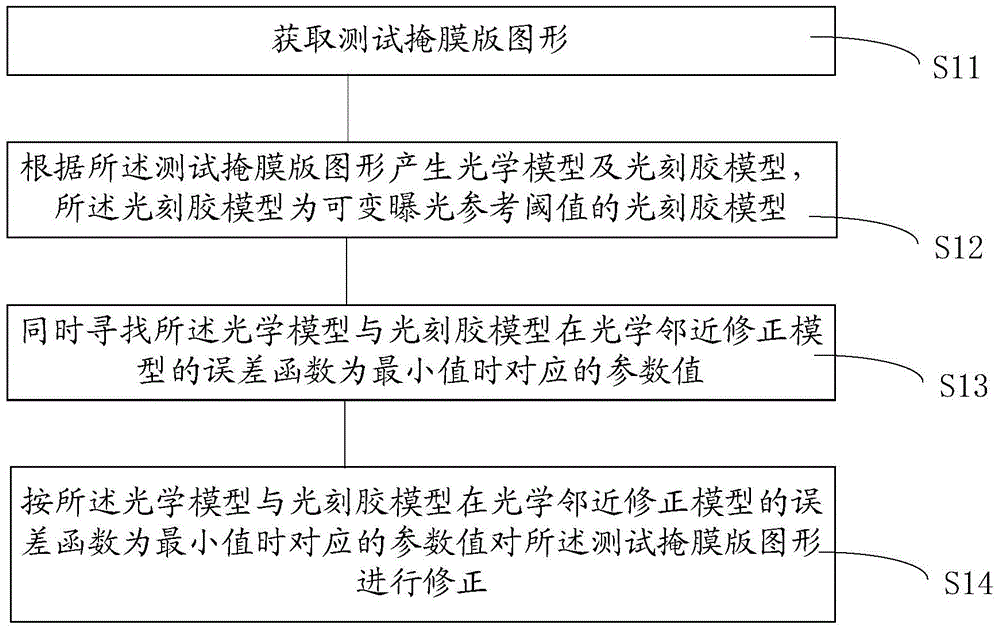

[0037] As mentioned in the Background Art, refer to figure 1 The parameters obtained by the existing optical proximity correction method shown are not ideal in the actual optical proximity correction process. After analysis, it is found that the reason is: through the optical model and the matching photoresist model (constant threshold resist model) with a fixed reference exposure threshold, the values of the parameters of the optical model corresponding to the optimal value of the optical proximity correction model are only Focuses on the mathematical fitting process and does not consider the physical properties of the optical proximity correction model. In other words, the exposure reference threshold of the photoresist model corresponding to each parameter value in the optical model is not the same. Therefore, the optical proximity correction model obtained by using the photoresist model with a fixed exposure reference threshold corresponds to the optical model at the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com