Luminance and chrominance correction production line for LED (light-emitting diode) display modules

A display module, brightness and chromaticity technology, applied in the direction of static indicators, instruments, etc., can solve the problems of long time-consuming manual calibration, inability to collect images of multiple cabinets, and affect data collection of LED cabinets, so as to reduce calibration manpower and reduce Inaccurate data collection and the effect of avoiding data collection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

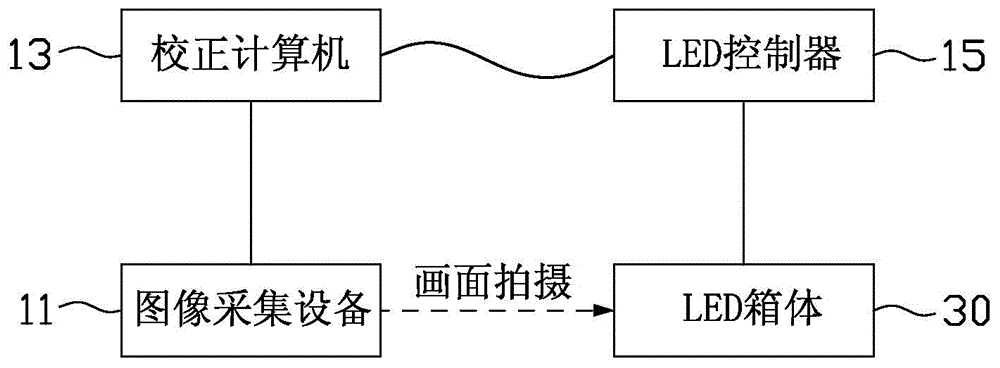

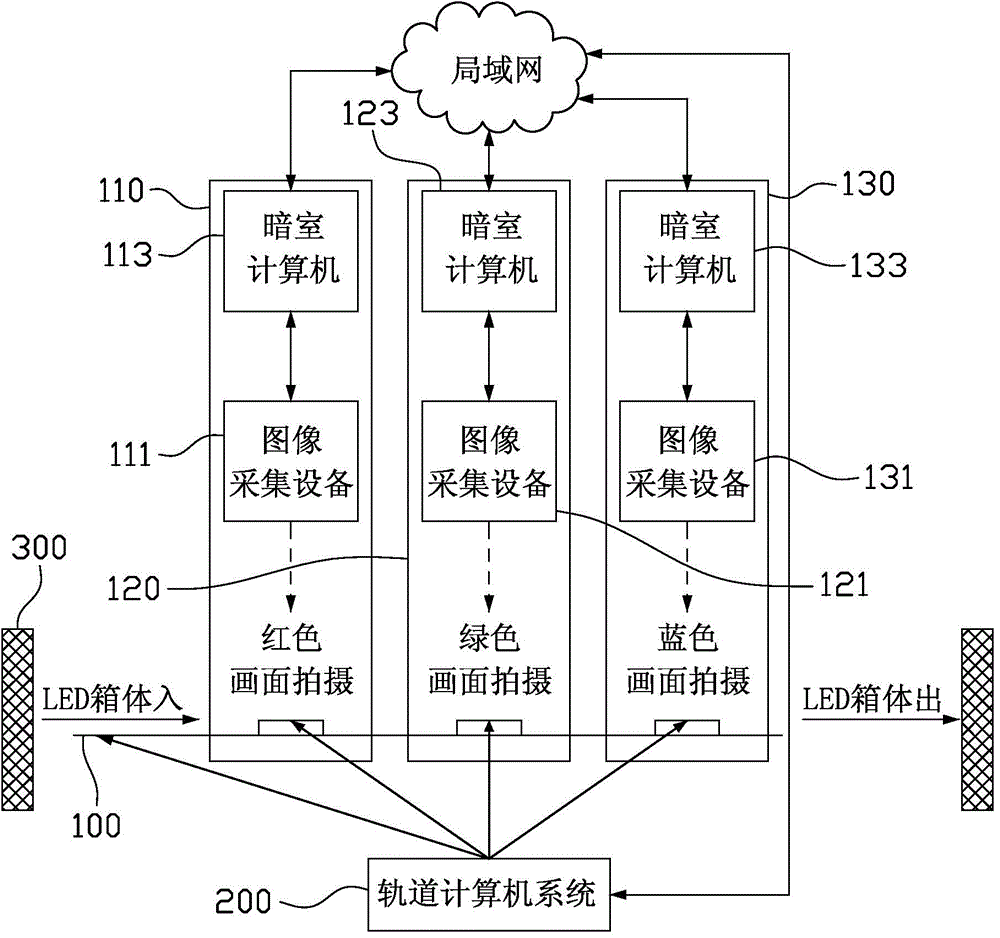

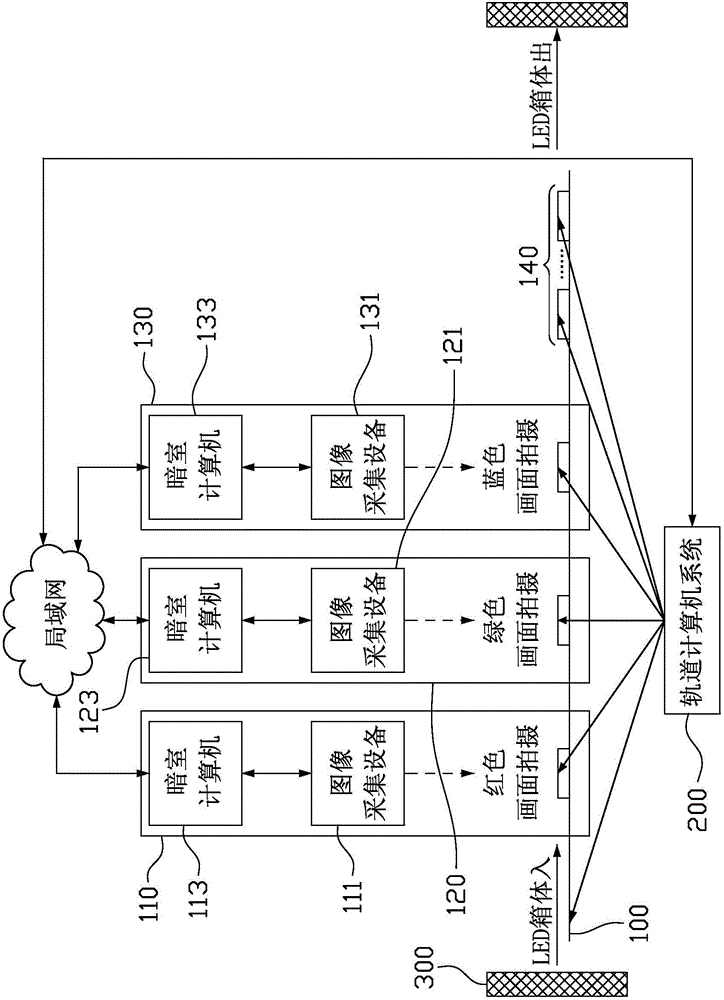

[0026] See figure 2 , which is a schematic diagram of the system architecture of a production line for brightness and chromaticity correction of LED display modules according to an embodiment of the present invention. Such as figure 2 The LED display module brightness and chromaticity correction production line includes: a track 100, a plurality of darkroom stations 110, 120, 130 arranged on the track 100, image acquisition equipment 111, 121, 131, darkroom computers 113, 123, 133 and a track computer system 200.

[0027] The image acquisition devices 111, 121, 131 are respectively arranged in the darkroom workstations 110, 120, 130, and the darkroom computers 113, 123, 133 are signally connected to the image acquisition devices 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com