Passive water replenishment and heat export system for spent fuel pool

A spent fuel pool and heat export technology, applied in the field of safety systems, can solve problems such as accident handling obstacles, temperature rise, damage, etc., to achieve the effects of preventing damage, effective cooling, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

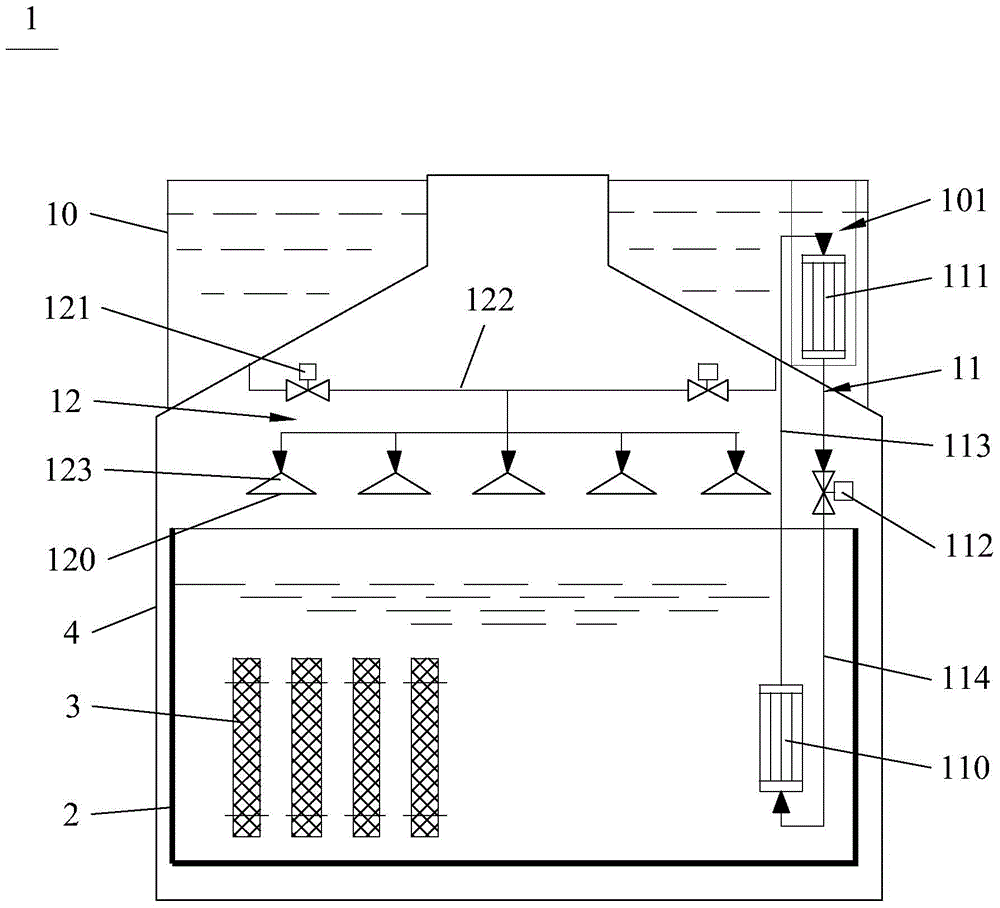

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings of the specification.

[0019] Such as figure 1 As shown, the passive water make-up and heat export system 1 for a spent fuel pool of the present invention includes a cooling pool 10, a loop heat pipe system 11, and a spray system 12. The cooling pool 10 is arranged above the spent fuel pool 2, and the loop The heat pipe system 11 has a closed loop structure and one end is set in the spent fuel pool 2 and the other end is set in the cooling pool 10, the loop heat pipe system 11 has a condensing medium, and the spray system 12 is set in Between the spent fuel pool 2 and the cooling pool 10 and in communication with the cooling pool 10, the spray system 12 includes a water spray port 120 for replenishing coolant in the spent fuel pool 2 and communicating or blocking the The spraying valve 121 of the cooling pool 10 and the spray port 120 is activated.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com