Silicon slice prealignment device and method

A pre-aligned, silicon wafer technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inaccurate positioning, and achieve the effect of eliminating interference and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the technical solutions of the above invention in more detail, specific embodiments are listed below to prove the technical effect; it should be emphasized that these embodiments are used to illustrate the present invention and not limit the scope of the present invention.

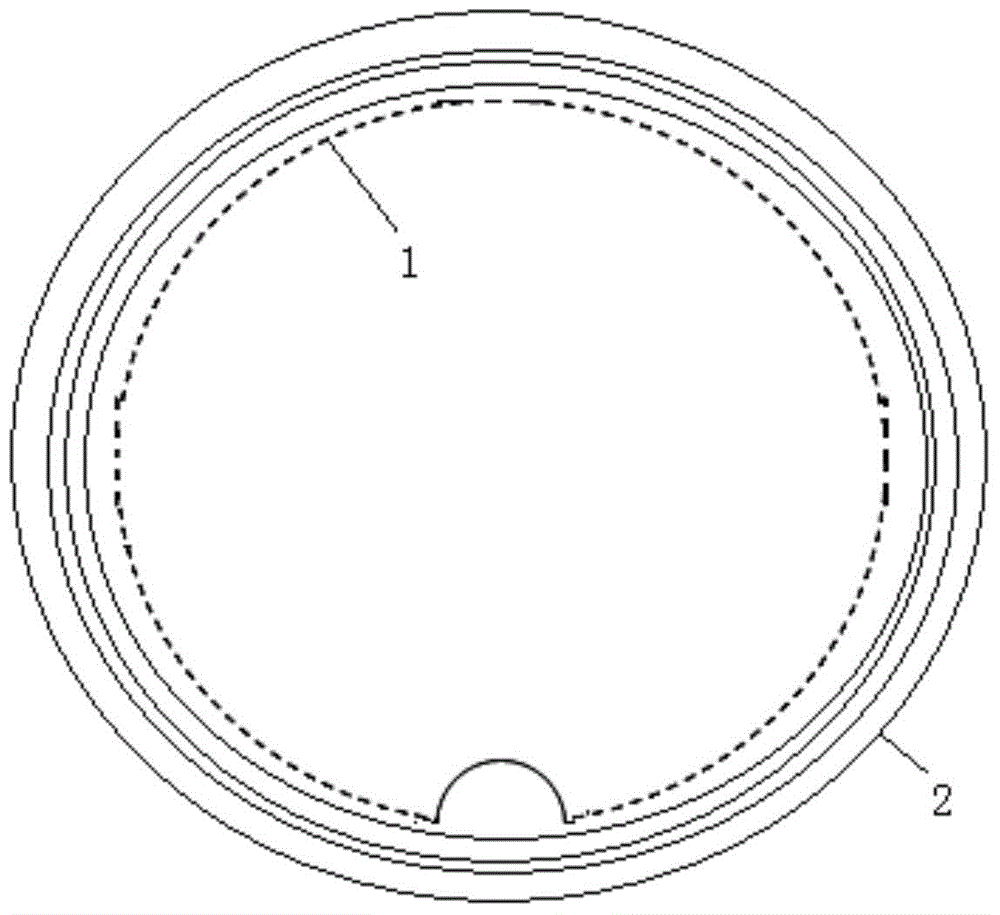

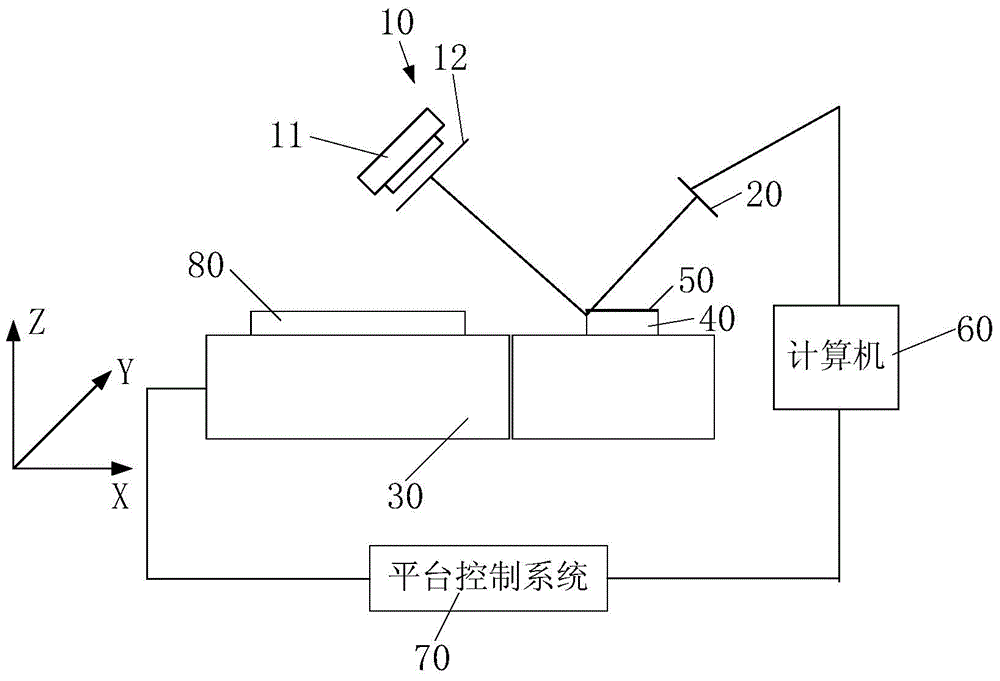

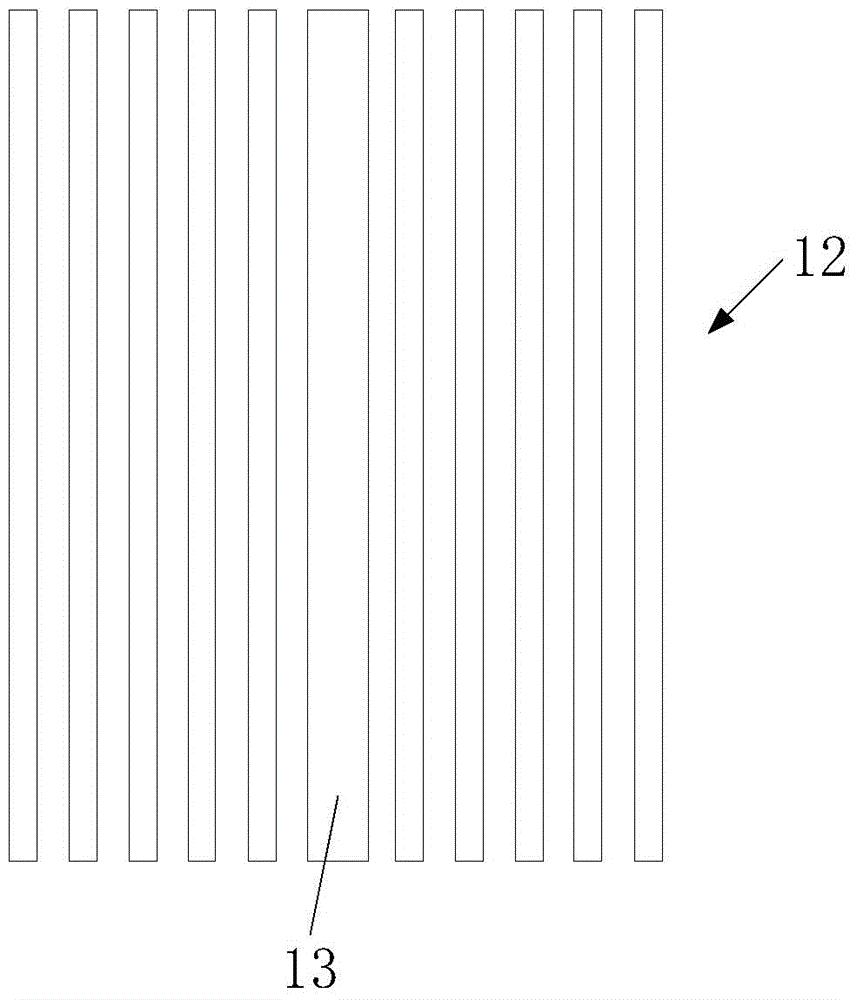

[0036] The silicon wafer pre-alignment device and method thereof provided by the present invention, such as figure 2 As shown, the device includes a structured light emission system 10, an imaging system 20, a workpiece table 30, a reference plate 40, a marker plate 50, a computer 60, and a platform control system 70. The silicon wafer 80 and the reference plate 40 are placed on the workpiece table, respectively. 30, the marking plate 50 is placed on the reference plate 40, the projection beam emitted by the structured light emission system 10 is irradiated to the edge of the reference plate 40, and the detection beam reflected by the projection beam is captured by the imaging s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com