Method and tool for treating heating of drainage plate

A processing method and technology for processing tools, applied in the direction of manufacturing tools, hand-held tools, overhead line/cable equipment, etc., can solve the problems of complicated operation of the processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

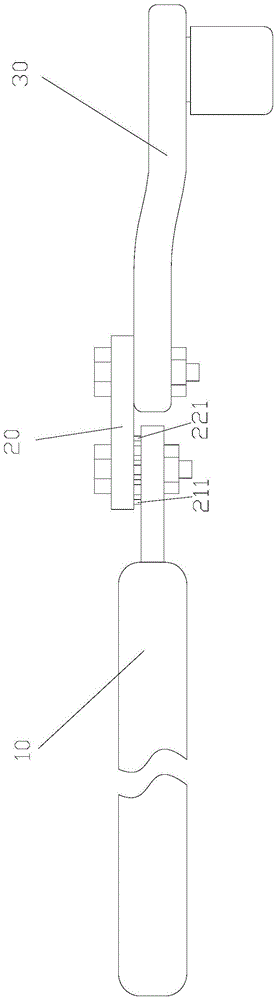

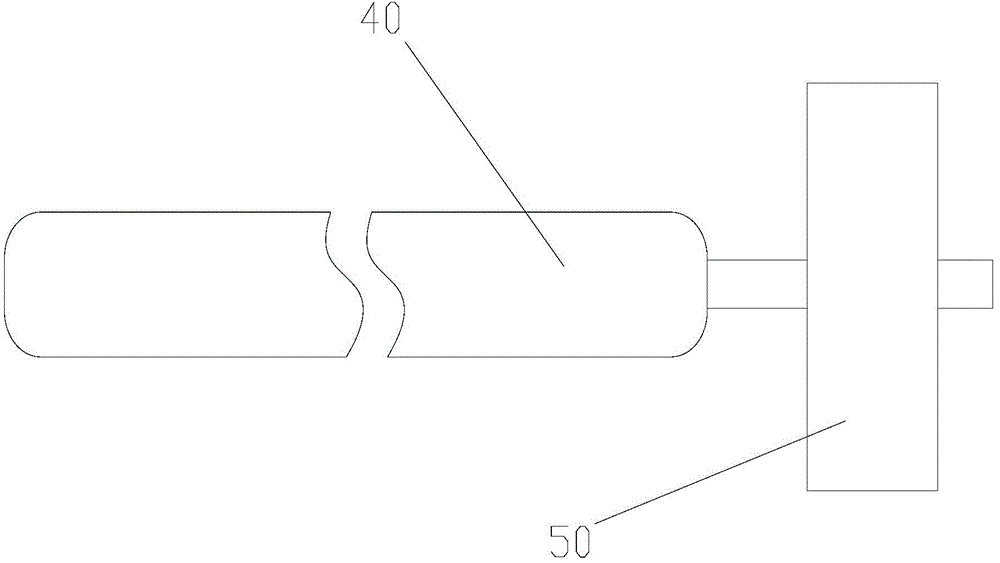

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

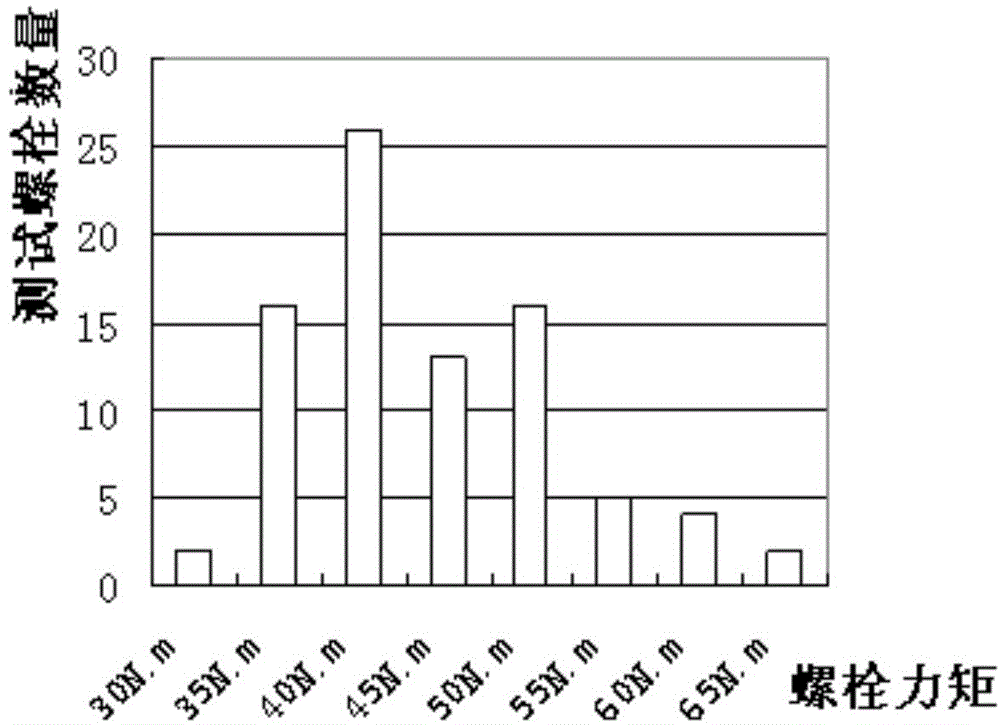

[0026] Aiming at the heat generation problem of the strain clamp drainage plate, the inventor of the present application conducted a series of tests and researches, and performed statistical analysis on the test results.

[0027] The inventor carried out temperature measurement and analysis on the diversion plates of multiple transmission lines. The inventor found that if the diversion plates generate heat due to problems with the installation process (not including bolts not firm) and raw materials, after the lines are put into operation It can be found in 1-2 times of temperature test analysis. If there is no heating phenomenon in the temperature test within two years of the line being put in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com