Tri-level four-leg T-shaped fault-tolerant converter and control method thereof

A technology of flat four-bridge and converter, applied in the field of three-level four-bridge T-type fault-tolerant converter and its control, to achieve the effect of good fault-tolerant operation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the drawings.

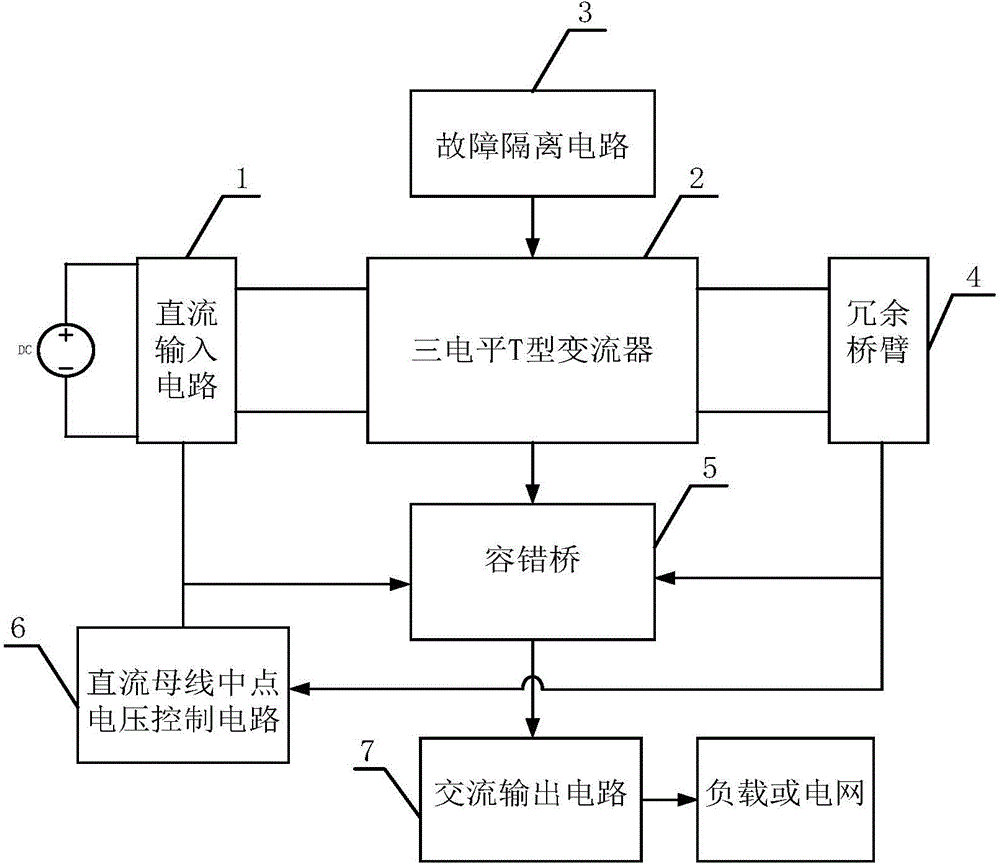

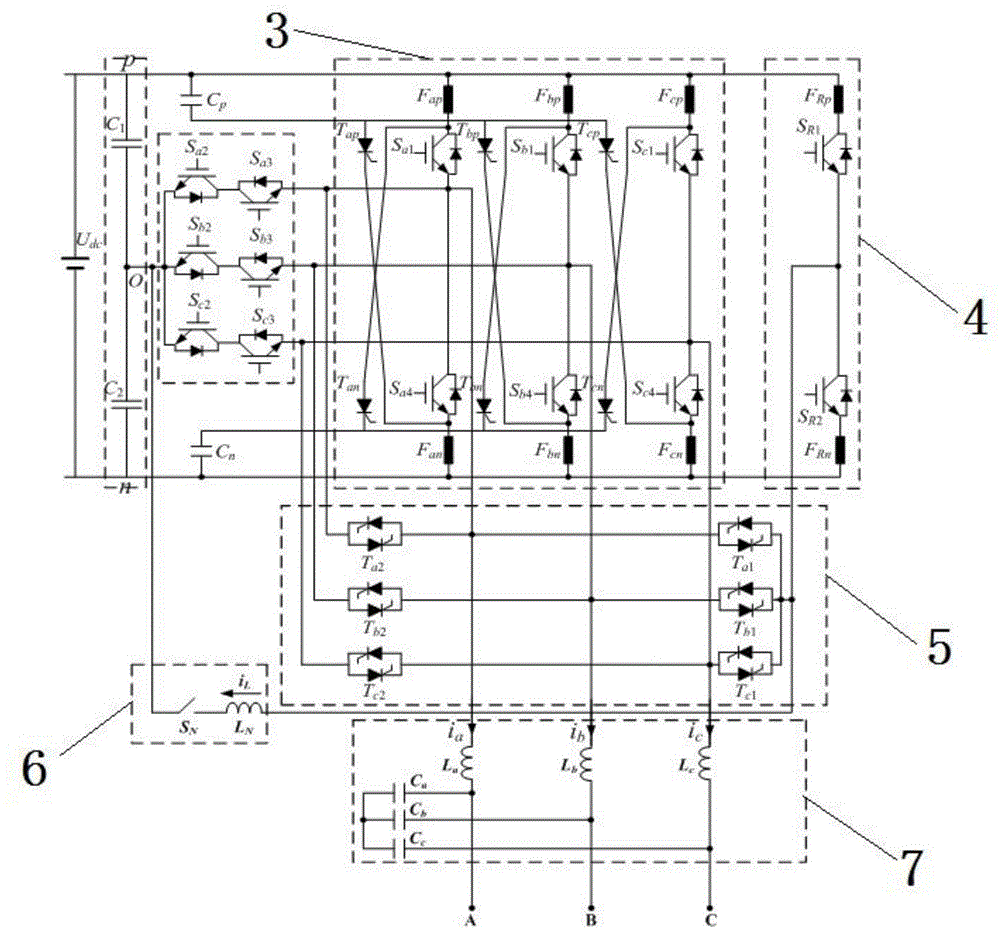

[0032] Such as figure 1 As shown, a three-level four-arm T-shaped fault-tolerant converter is characterized by including a DC input circuit 1, a three-level T-shaped converter 2, a fault isolation circuit 3, a redundant bridge arm 4, and a fault-tolerant Bridge 5, DC bus midpoint voltage control circuit 6 and AC output circuit 7;

[0033] The DC input circuit 1 consists of two electrolytic capacitors C 1 And C 2 The series connection is used to output electric energy to the converter. Before the converter is put into operation, first charge the DC input circuit through the DC source.

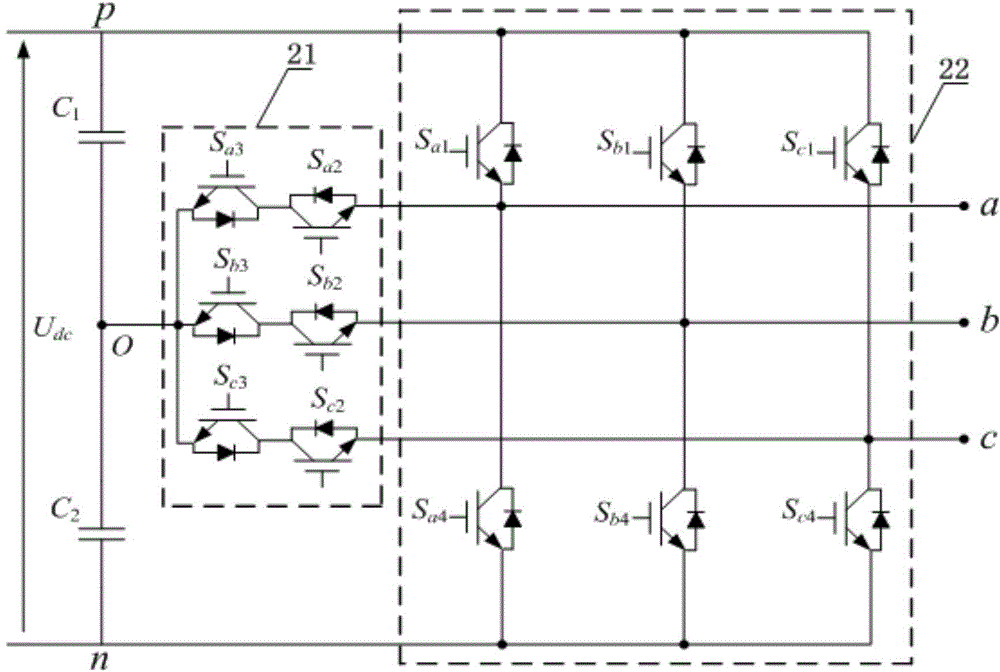

[0034] Such as image 3 As shown, the three-level T-shaped converter 2 includes a midpoint clamped bridge arm 21 and a two-level bridge arm 22; one end of the midpoint clamped bridge arm 21 is connected to the midpoint of the two-level bridge arm 22, The other end is connected to the midpoint of the DC in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com