A passive light-splitting rs-485 optical fiber bus embedded terminal

A RS-485, embedded terminal technology, applied in the field of industrial manufacturing, can solve the problem of not guaranteeing high-speed long-distance communication requirements, communication rate drop, etc., to achieve the effects of wide dynamic range, reduced pulse width distortion, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

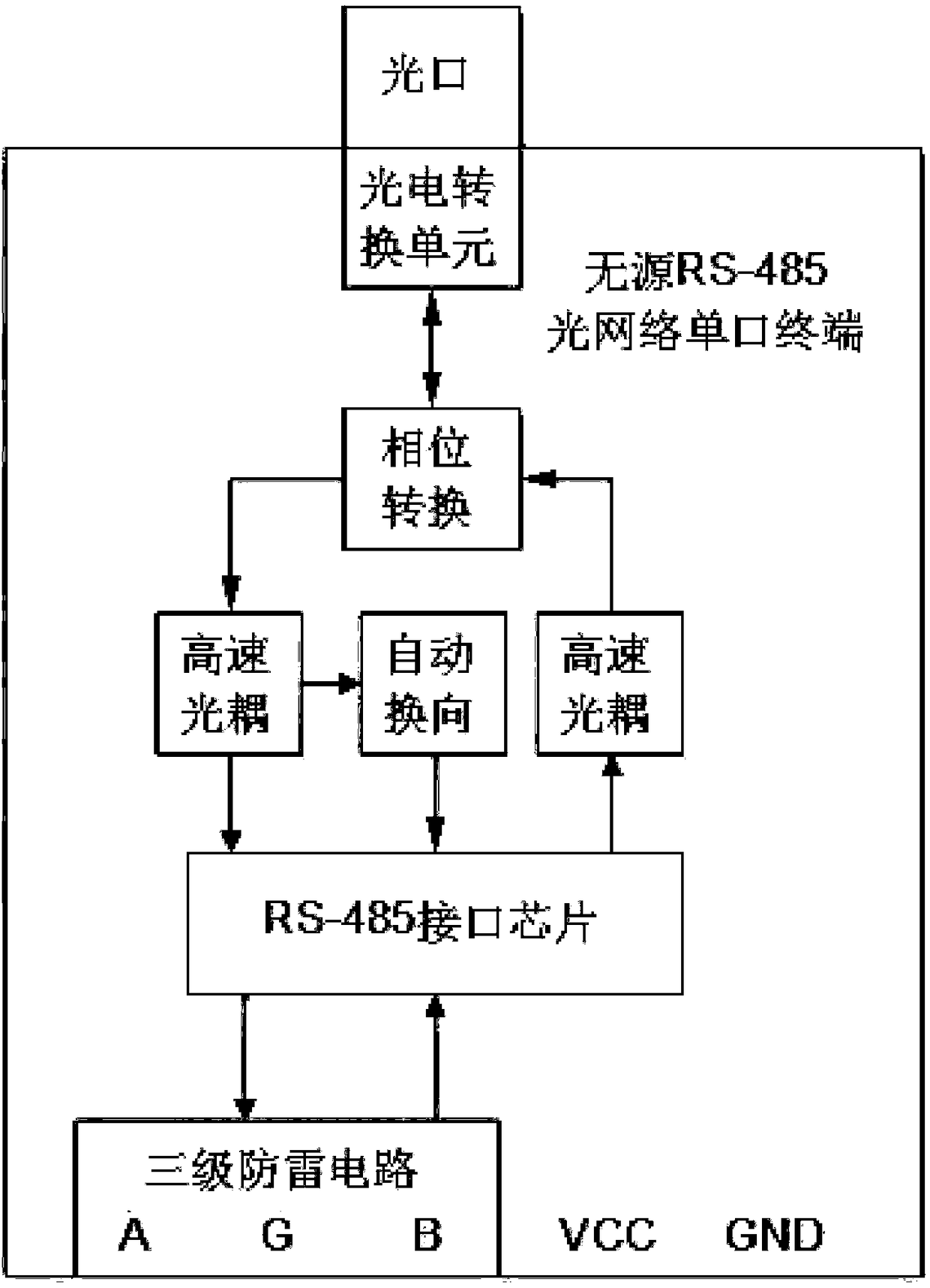

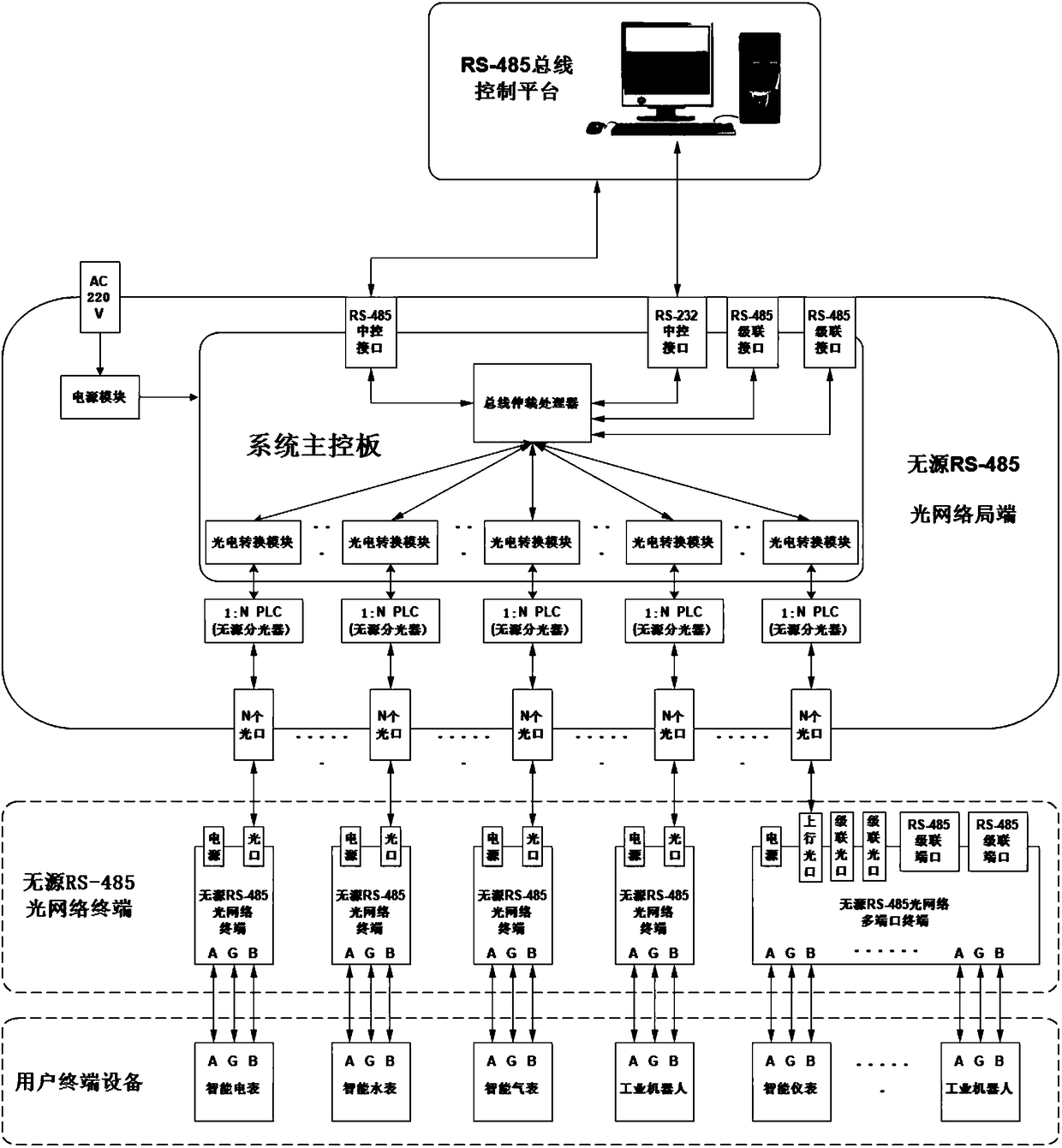

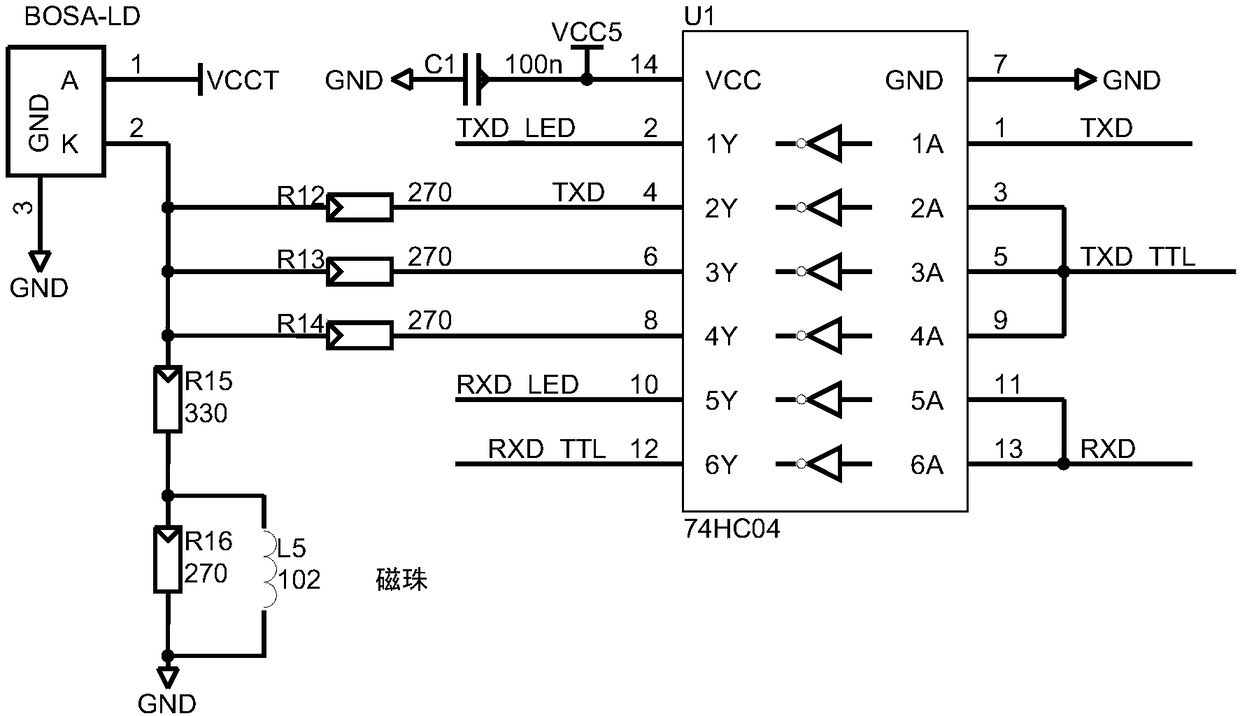

[0035] Example: see Figure 1 to Figure 8 This embodiment provides a passive RS-485 optical fiber bus embedded terminal, the two ends of which are respectively connected to the passive RS-485 optical network central office and terminal equipment of the passive optical RS-485 optical bus, which include a power module , Photoelectric conversion unit, RS-485 driver chip, high-speed optocoupler isolation circuit, non-polarity automatic transceiver commutation circuit and three-level lightning protection circuit, among which the photoelectric conversion unit is connected to one end of the high-speed optocoupler isolation circuit, and the high-speed optocoupler isolation circuit is another One end is connected to the non-polarity automatic transceiver commutation circuit and the RS-485 driver chip, and the RS-485 driver chip is connected to the three-level lightning protection circuit; the photoelectric conversion unit includes a transmitting unit and a receiving unit; the transmittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com