Controlled directional solidification of silicon

A technology of directional solidification and crucibles, applied in self-solidification, polycrystalline material growth, crystal growth, etc., can solve the problems of expensive and difficult to maintain cooling or heating conduits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

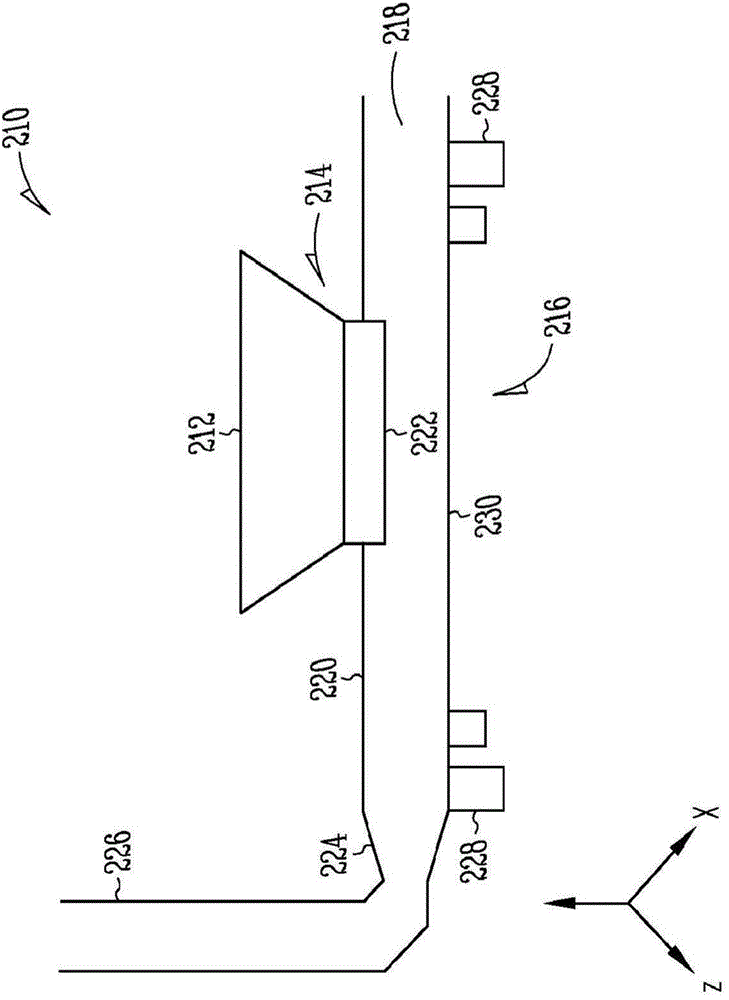

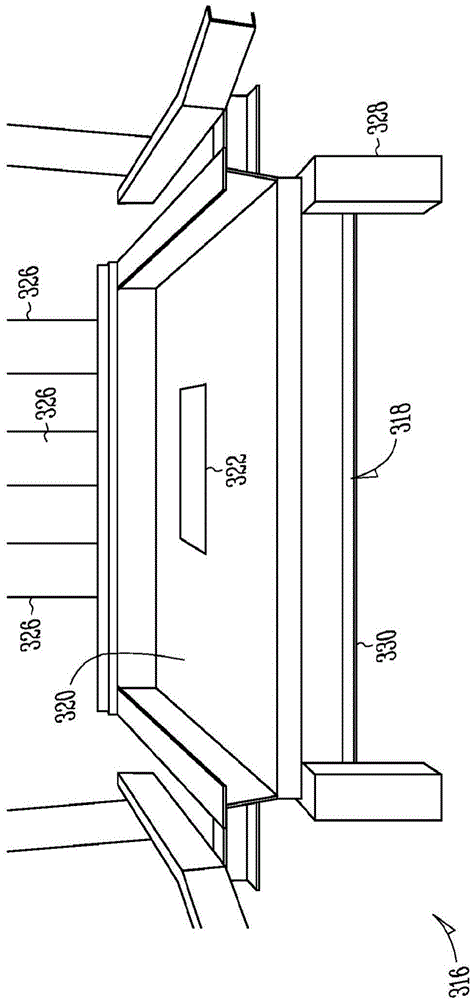

[0146] Embodiment 1 provides an apparatus for directional solidification comprising: a directional solidification crucible comprising a bottom; and a cooling platform comprising: a first surface defining an aperture configured to receive the directional solidification a portion of the bottom of the crucible, and a cooling conduit configured to provide a portion of the forced air to the portion of the bottom of the directional solidification crucible.

Embodiment approach 2

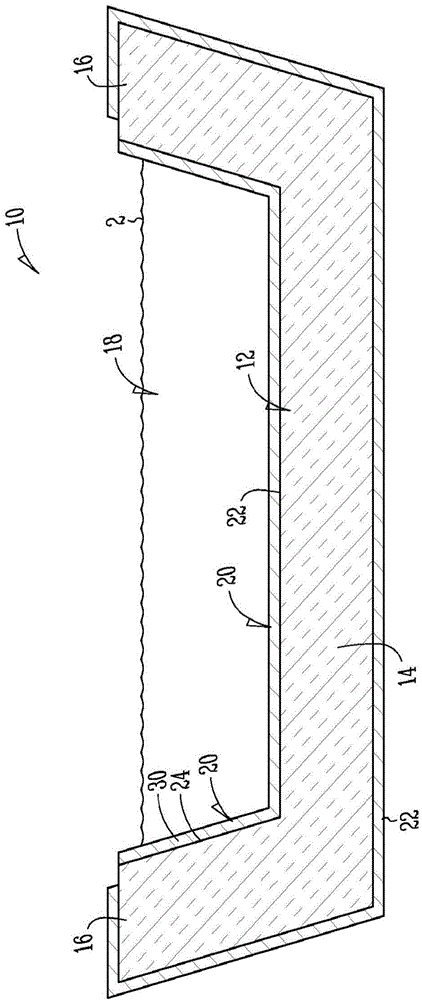

[0147] Embodiment 2. The apparatus of embodiment 1, wherein a plurality of sidewalls of the directionally solidified crucible comprise a hot face refractory material.

Embodiment approach 3

[0148] Embodiment 3. The apparatus of Embodiment 1 or 2, wherein the bottom of the directional solidification crucible comprises a conductive refractory material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com