Automatic engine stopping/restarting device

An automatic stop, engine technology, applied in the direction of engine starting, engine motor starting, engine components, etc., can solve problems such as delays, and achieve the effects of reducing fuel consumption, reducing noise, and increasing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, an embodiment will be described with reference to the drawings.

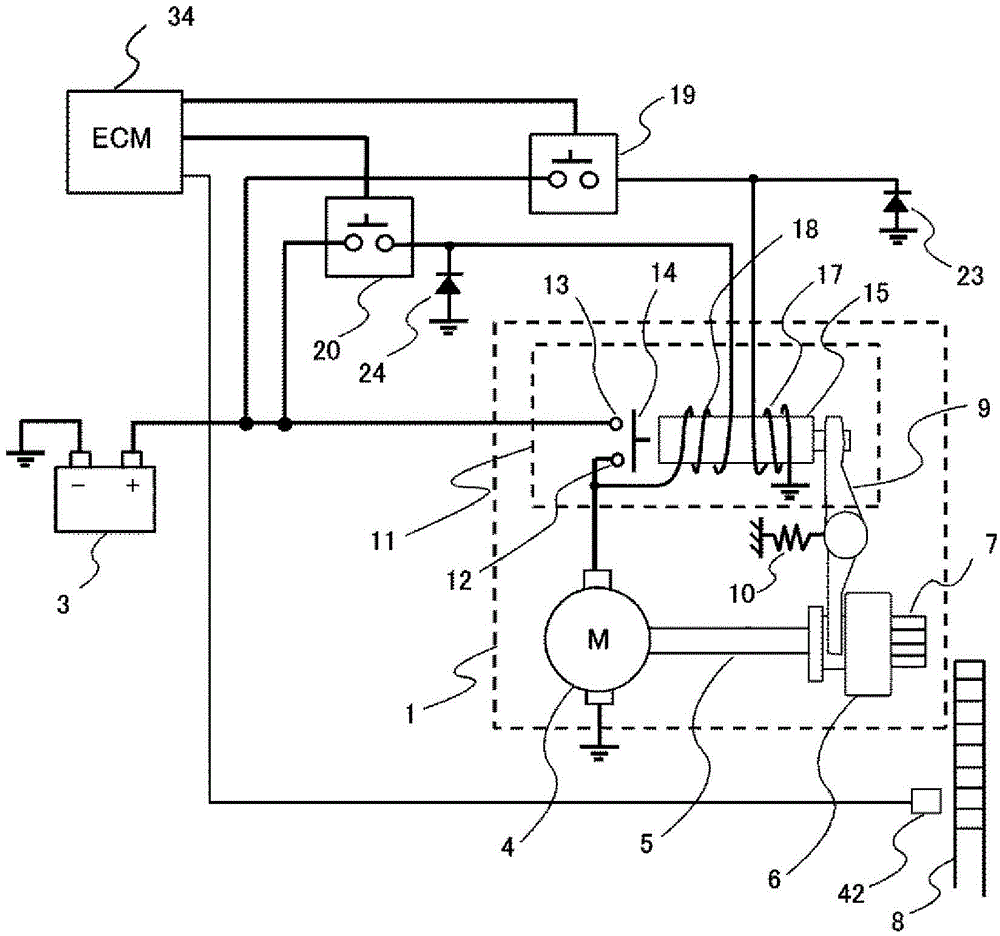

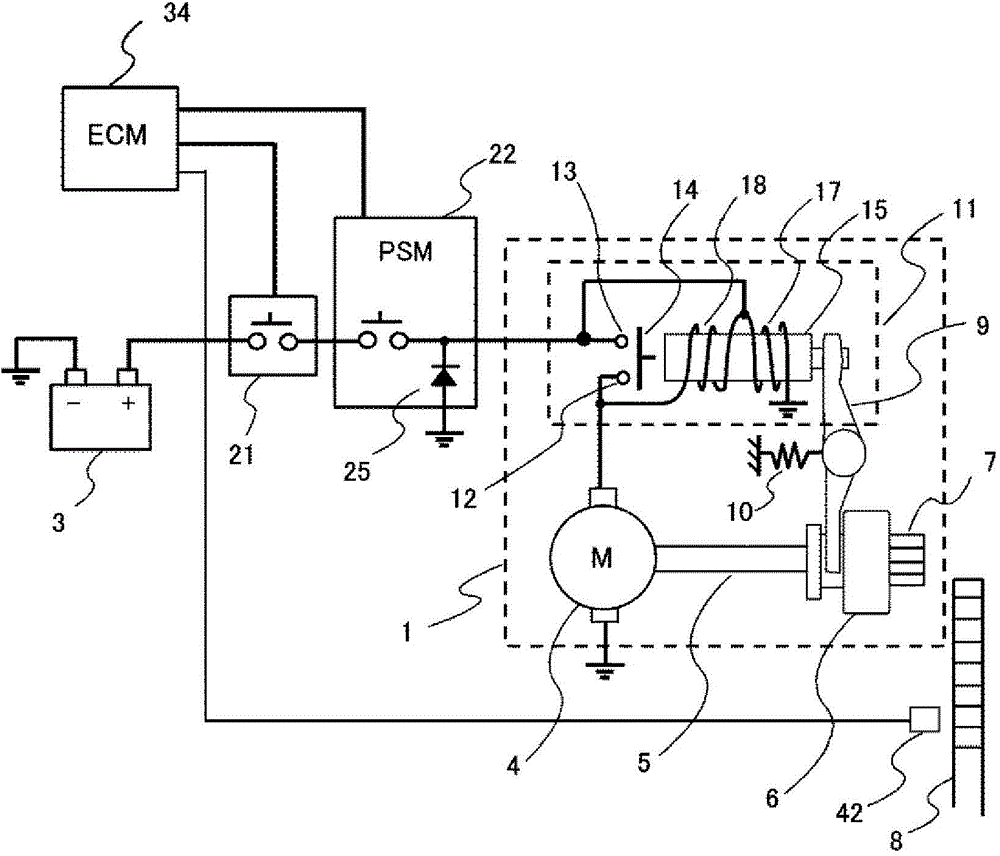

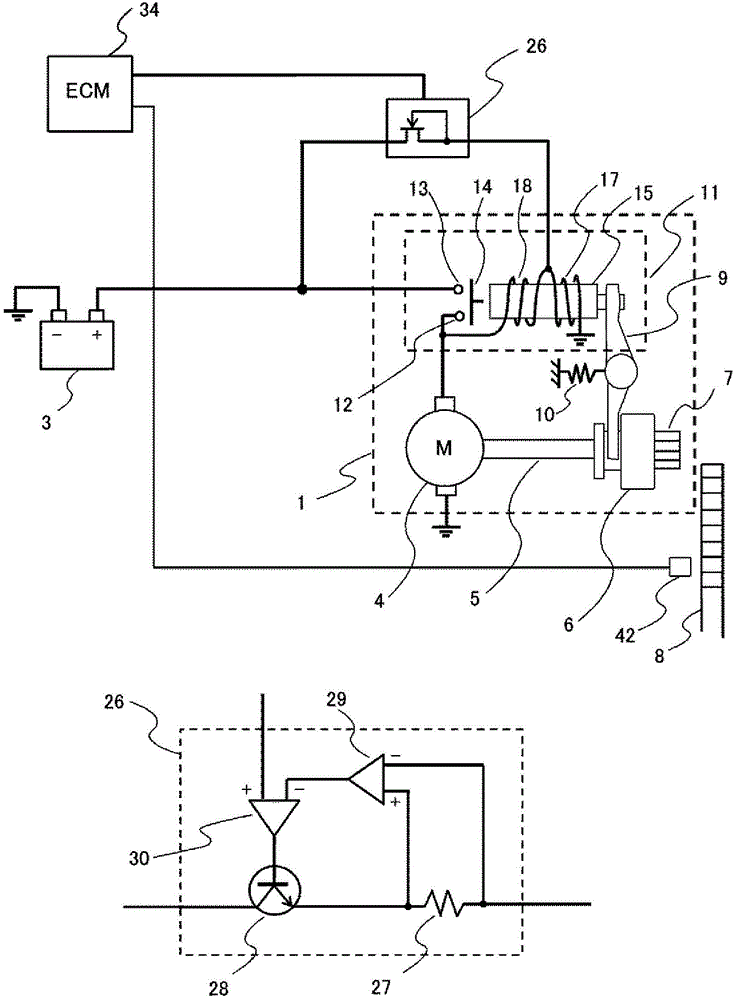

[0032] figure 1 It is a figure which shows the structure of the engine automatic stop restart apparatus in the 1st Example in this invention. The starter 1 is attached to a cylinder block (not shown) of the engine, and is connected to the battery 3 through wiring. When the electric motor 4 is energized, a rotational force is transmitted through the output shaft 5 to rotate a pinion 7 integrally formed with a one-way clutch 6 . The ring gear 8 is directly connected to a crankshaft (not shown) of the engine, and when the ring gear 8 meshes with the pinion gear 7, the power of the electric motor 4 is transmitted. When the pinion gear 7 is engaged, any one or both of the electromagnetic coils 17, 18 in the electromagnetic switch 11 is energized to generate a magnetic attraction force, thereby attracting the plunger (plunger) 15, through the shift lever ( shift lever) 9 to transmit its action t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com