Method for prelithiation, method for fabricating lithium secondary battery comprising the method, and lithium secondary battery fabricated from the fabricating method

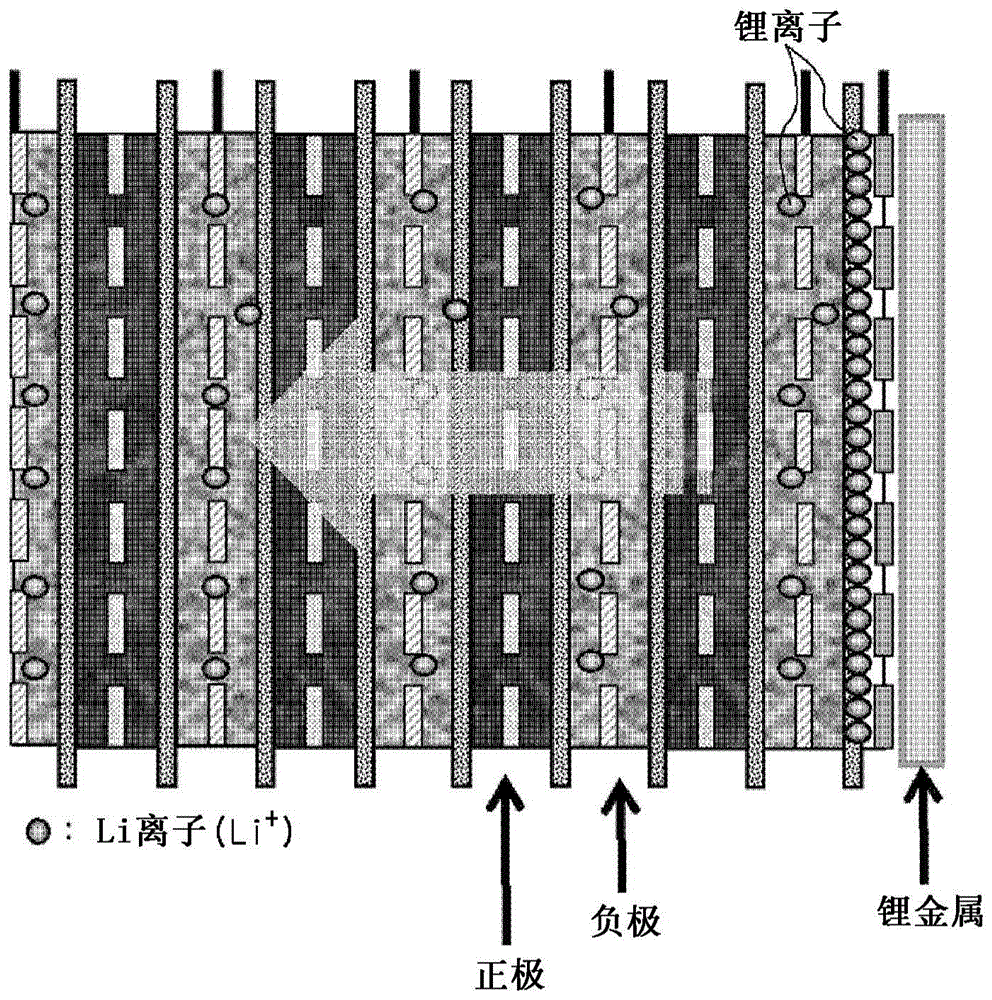

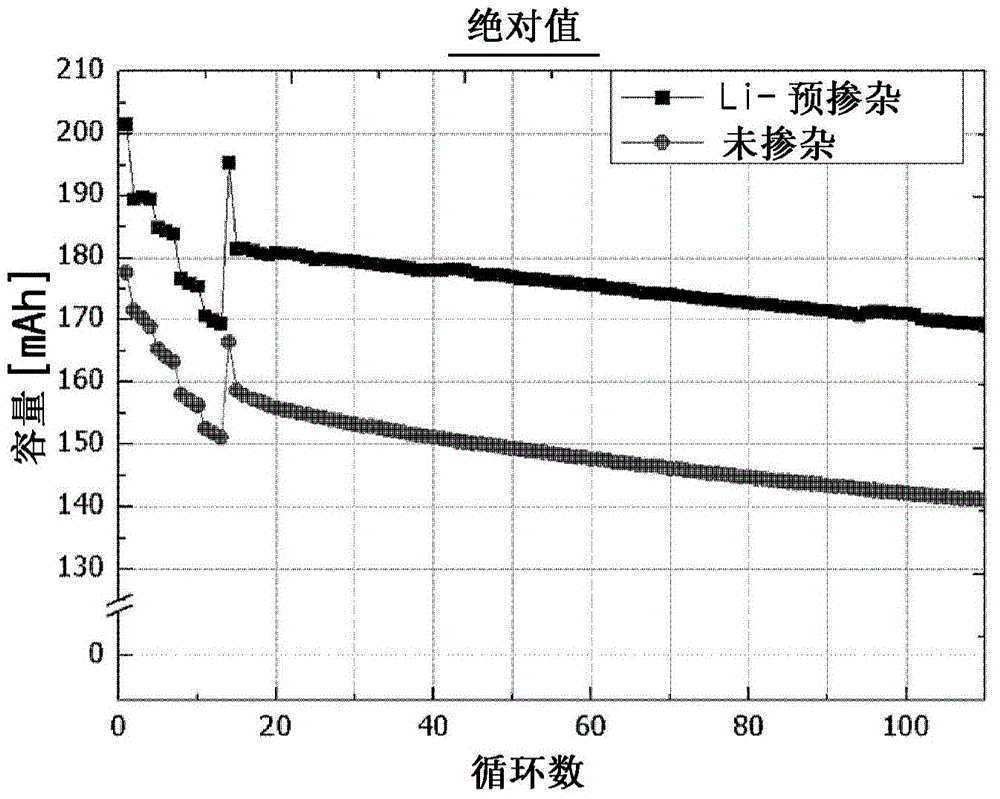

一种预锂化、单元电池的技术,应用在预掺杂锂领域,能够解决容量下降、电流电阻增大、电极活性材料与集电器接触面积下降等问题,达到提高容量和循环寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

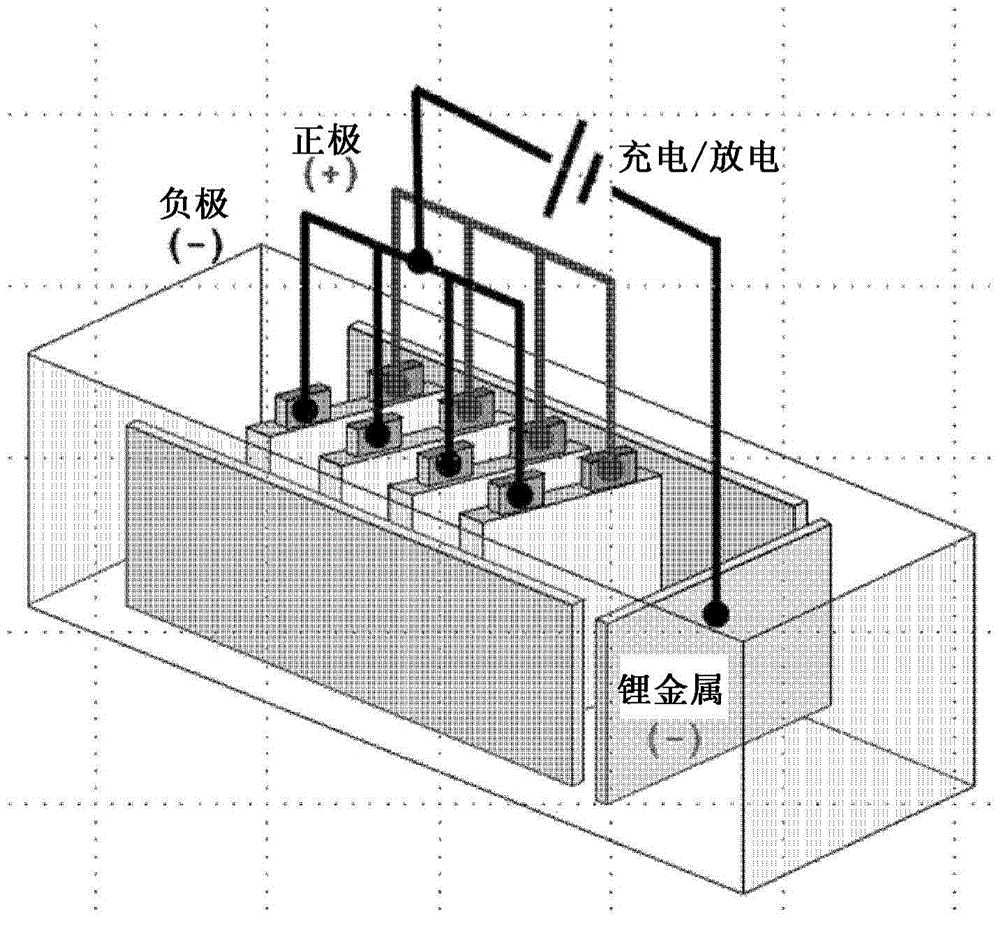

[0065] Prepare a positive electrode active material in which a three-component system consisting of Ni, Co, and Mn, or a spinel structure such as LiM is coated on an aluminum foil serving as a positive electrode current collector. 2 o 4 (M=Mn, Ni 0.5 mn 1.5 , CoMn), or olivine-structured cathode active materials such as LiMPO 4 (M=Fe, Mn, Co) positive electrode, and prepare a negative electrode in which a Si-based negative electrode active material is coated on a copper foil as a negative electrode current collector, and pass to provide a porous film as a separator between the positive electrode and the negative electrode At least one unit cell was prepared by roll forming the positive electrode and the negative electrode by means of a polyethylene film. The prepared unit cells were arranged in a reaction tank, and electrodes of the same polarity were connected by cables.

[0066] LiPF containing 1M as lithium salt 6 And an electrolyte solution of a mixture of ethylene ca...

Embodiment 2

[0069] A lithium secondary battery was manufactured by the same method as in the above-described examples, except that the positive electrode and the negative electrode included leads connected thereto through tabs, and predoping was performed by connecting the respective leads.

[0070] In this way, in the case of a stacked cell structure, a parallel predoping of the stacked cells is achieved instead of a predoping of the individual electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com