Vehicle sunroof production equipment

A technology for production equipment and automobile sunroofs, applied in metal processing equipment, vehicle parts, clamping, etc., can solve the problems of cumbersome installation steps, inconvenient operation, low productivity and cost of manual installation, so as to avoid manual movement and improve efficiency , The effect of solving the difficulty of reed installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

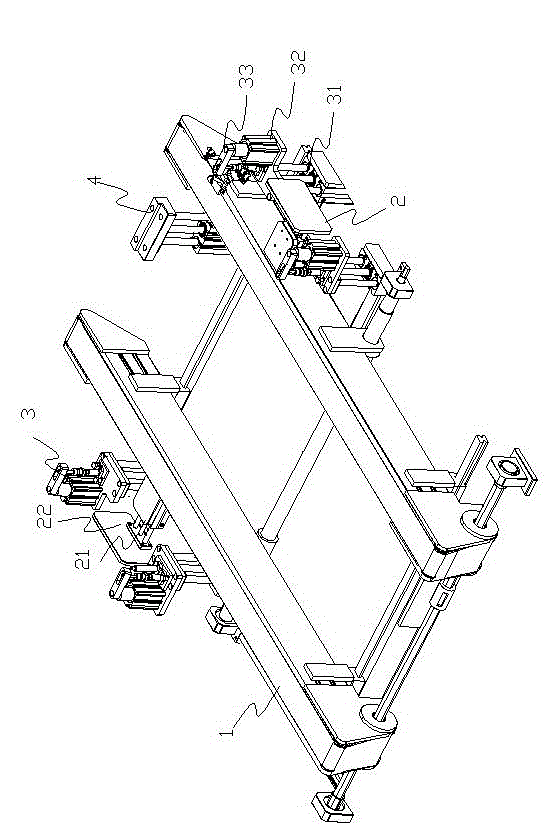

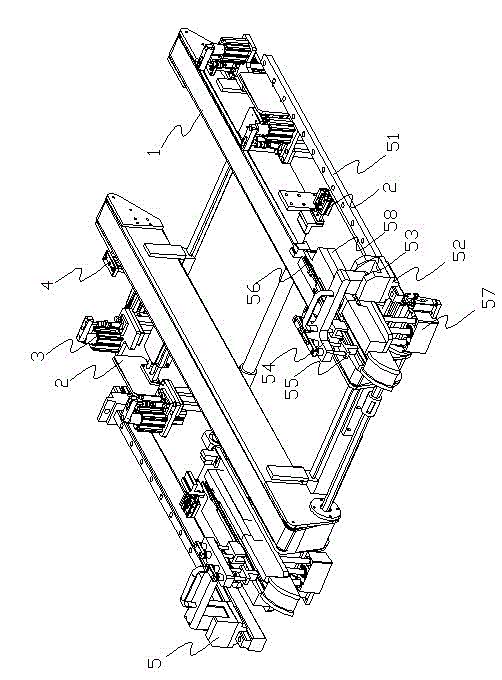

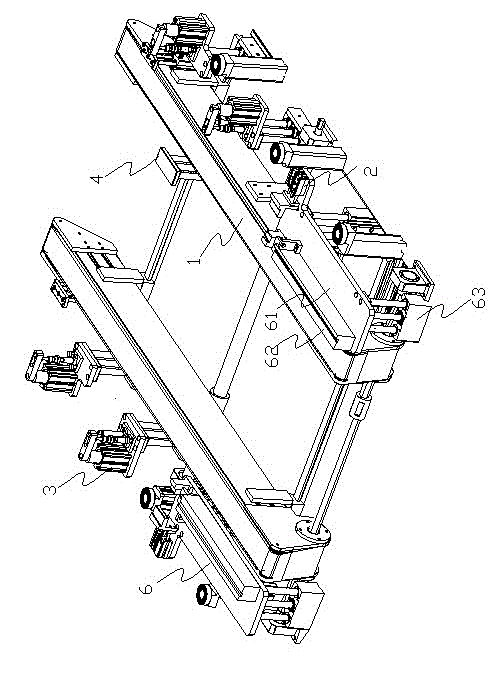

[0037] As shown in the figure, an automobile sunroof production equipment includes a beam and guide rail riveting station connected in sequence, a front frame riveting station, a chain tube assembly and wind deflector installation station, a mechanical group installation station, and a sun visor installation station. Workstation, glass and motor installation station, initial run-in station, surface difference test station and noise test station;

[0038] The beam and guide rail riveting station and the front frame riveting station are manual pre-sequence stations, both of which include a positioning device and a clamping device. The positioning device includes a plurality of positioning blocks and / or a plurality of positioning pins. The clamping device It includes four cylinders, and the protruding ends of the cylinders are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com