Belt-driven electric cylinder high-speed two-dimensional translational manipulator

A technology of electric cylinders and manipulators, which is applied to manipulators, program-controlled manipulators, and manufacturing tools. It can solve the problems of bloated robot structures and large footprints, and achieve compact overall structure, small footprints, kinematics and dynamics. good academic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

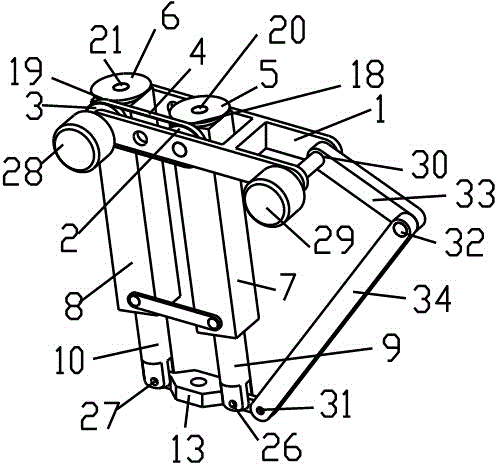

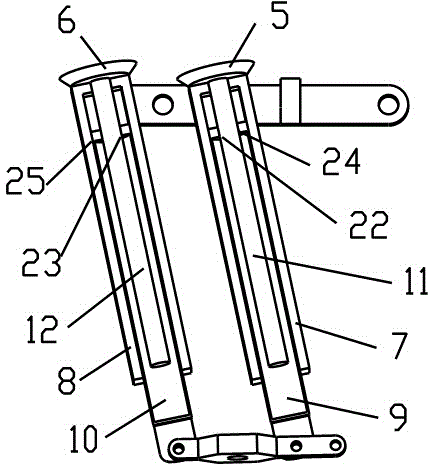

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

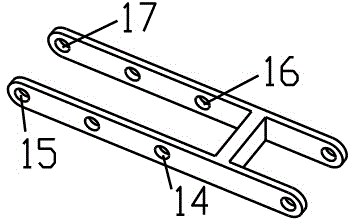

[0013] control figure 1 , figure 2 and image 3 , high-speed two-translational manipulator with drive electric cylinder, including frame 1, first transmission wheel 2, second transmission wheel 3, first bevel gear 5, second bevel gear 6, first outer rod 7, second outer rod 8. The first screw mandrel 11, the second screw mandrel 12, the first nut rod 9, the second nut rod 10, the moving platform 13, the first motor 28, the second motor 29, the first transmission rod 33, the second transmission rod 34 and band 4.

[0014] The first transmission wheel 2 is connected with the frame 1 through the first rotating pair 14, the first transmission wheel 2 is connected with the second transmission wheel 3 through the belt 4, and the first transmission wheel 2 is connected with the first cone through the first gear pair 18. The gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com