Stamped and welded leaf spring seat for internal high-voltage axle housing and production method thereof

A technology of leaf spring and inner high pressure, applied in the direction of spring, spring/shock absorber, leaf spring, etc., can solve the problems of unreliable welding of inner high pressure axle housing body, heavy leaf spring seat, and many casting defects, etc. Low energy consumption, less process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

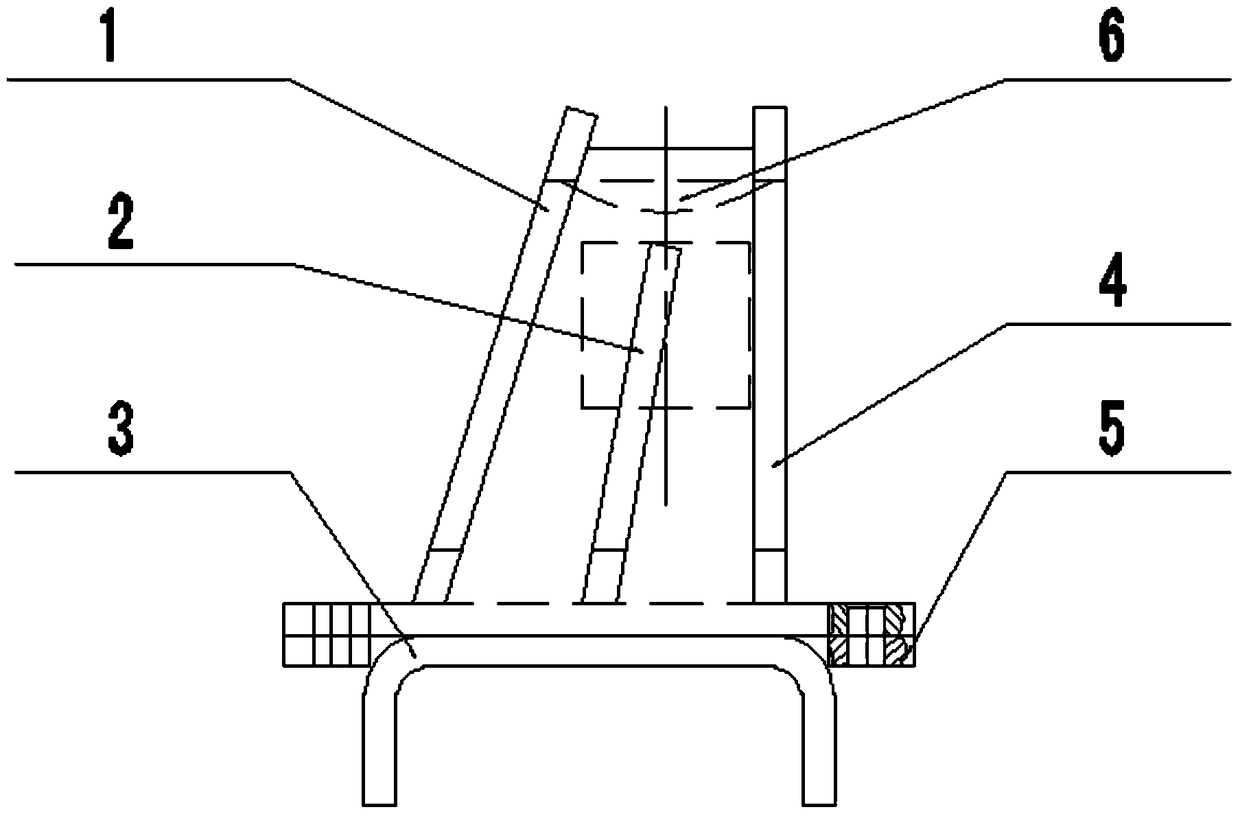

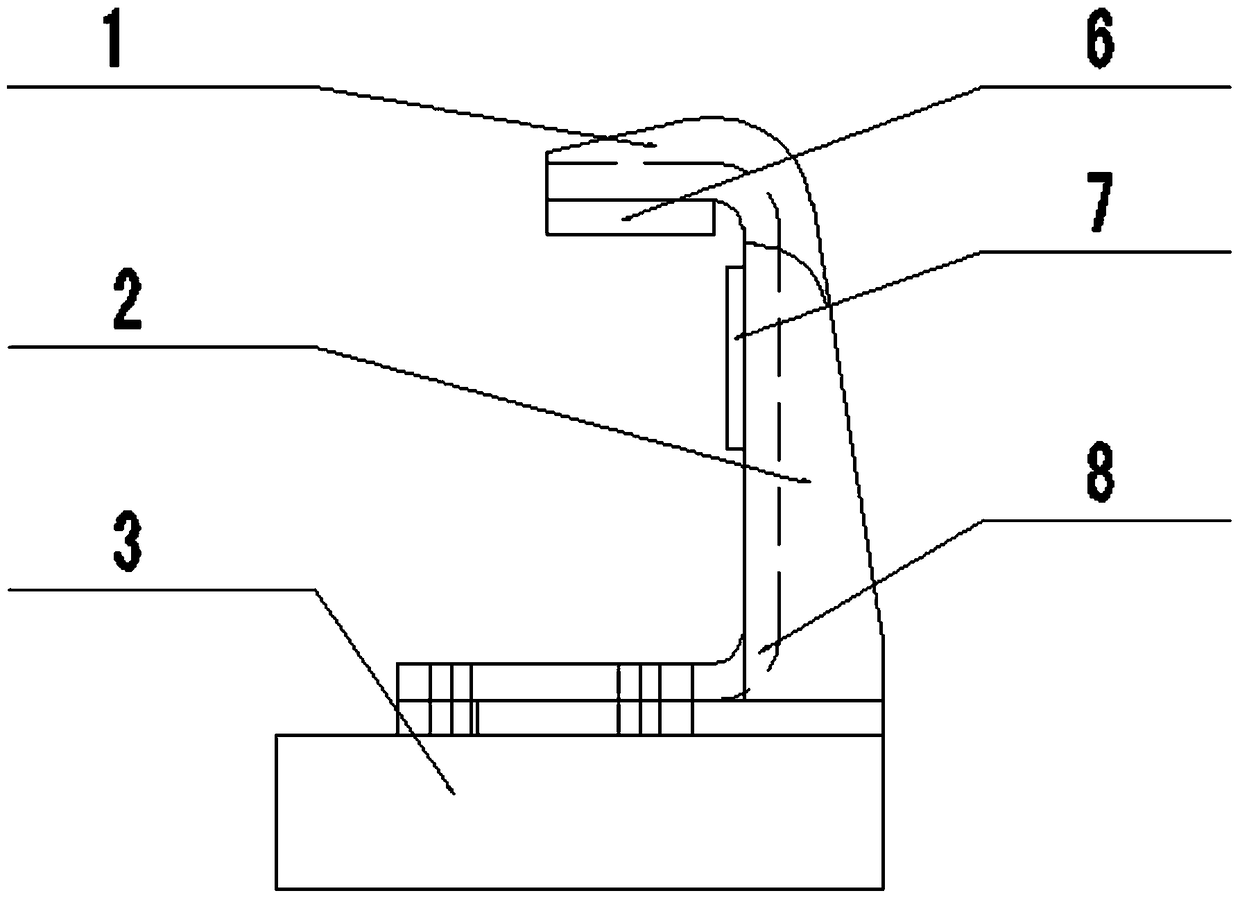

[0012] The structure of the stamped and welded leaf spring seat for the inner high-voltage axle housing of the present invention is as figure 1 , figure 2 As shown, including the bottom plate 3, a bent plate 8 is arranged above the joint of the bottom plate 3, and the bent plate 8 and the bottom plate 3 are stamped with bends respectively. The bending of the bottom plate 3 is "n" type, and the bending of the bent plate 8 is "J". ” type, and the bending direction is inconsistent, the bottom plate 3 supports the bent plate 8 and is welded together with the straight side hook plate 4 and the oblique side hook plate 1. The oblique side hook plate 1, the rib plate 2, the straight side hook plate 4 and the reinforcement plate 5 are spliced around the main body to reinforce the main body. The spliced parts are all welded by gas shielded weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com