egg packing box

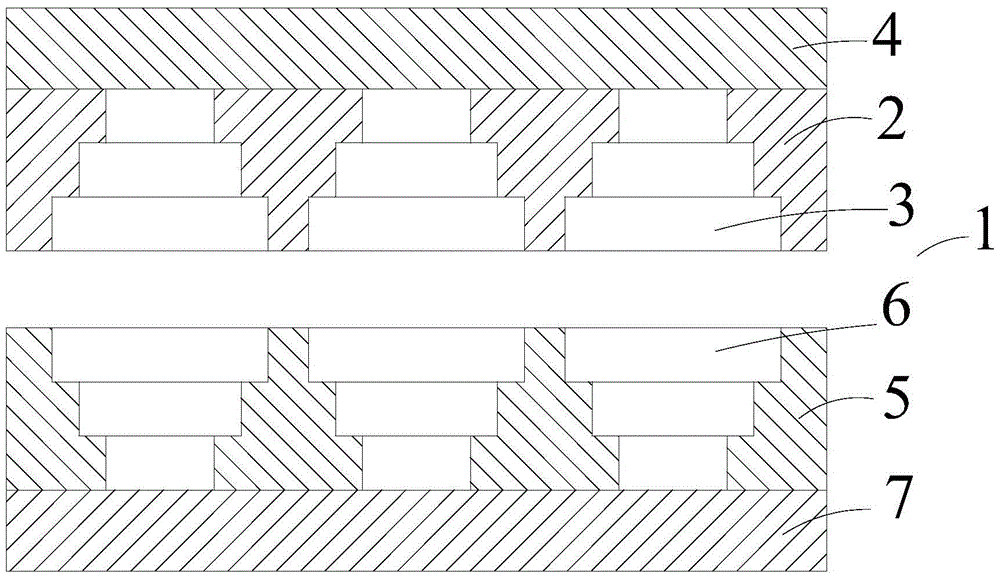

A technology for packaging boxes and eggs, which is applied in the field of egg packaging boxes for egg trays. It can solve problems such as poor vibration absorption, low shell hardness, and irregular shape. It is easy to achieve dimensional accuracy, low cost, and advanced processing equipment and processing technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028]According to a preferred embodiment of the present invention, the material of the upper shell 2 and the lower shell 5 is pearl cotton. Ordinary pearl cotton can be used for pearl cotton, and a good effect can be achieved with a foaming rate of more than 50%. Of course, other types of cushioning materials can also be used, such as EVA, PE, XPE, various modified rubbers, modified resins, etc. However, the processing cost and processing difficulty of these materials are generally high, and some materials have high hardness. It is higher than pearl cotton, and the breakage rate is close to zero.

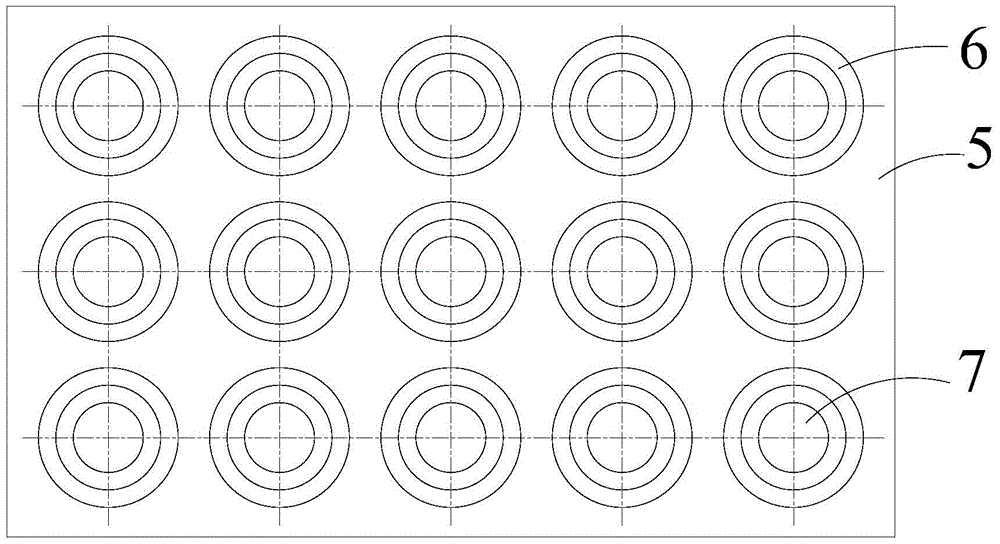

[0029] According to a preferred embodiment of the present invention, the number of steps between the upper recessed part 3 and the lower recessed part 6 is 3-4 layers. The stepped hole can be adjusted to four steps (three protruding right-angled sides) according to actual needs, but too many steps may increase the processing cost and difficulty, and because the protruding right-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com